Microwave plasma abatement apparatus

A microwave plasma and plasma technology, applied in separation methods, gas treatment, dispersed particle separation, etc., can solve problems such as reducing device destruction efficiency and microwave generator damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

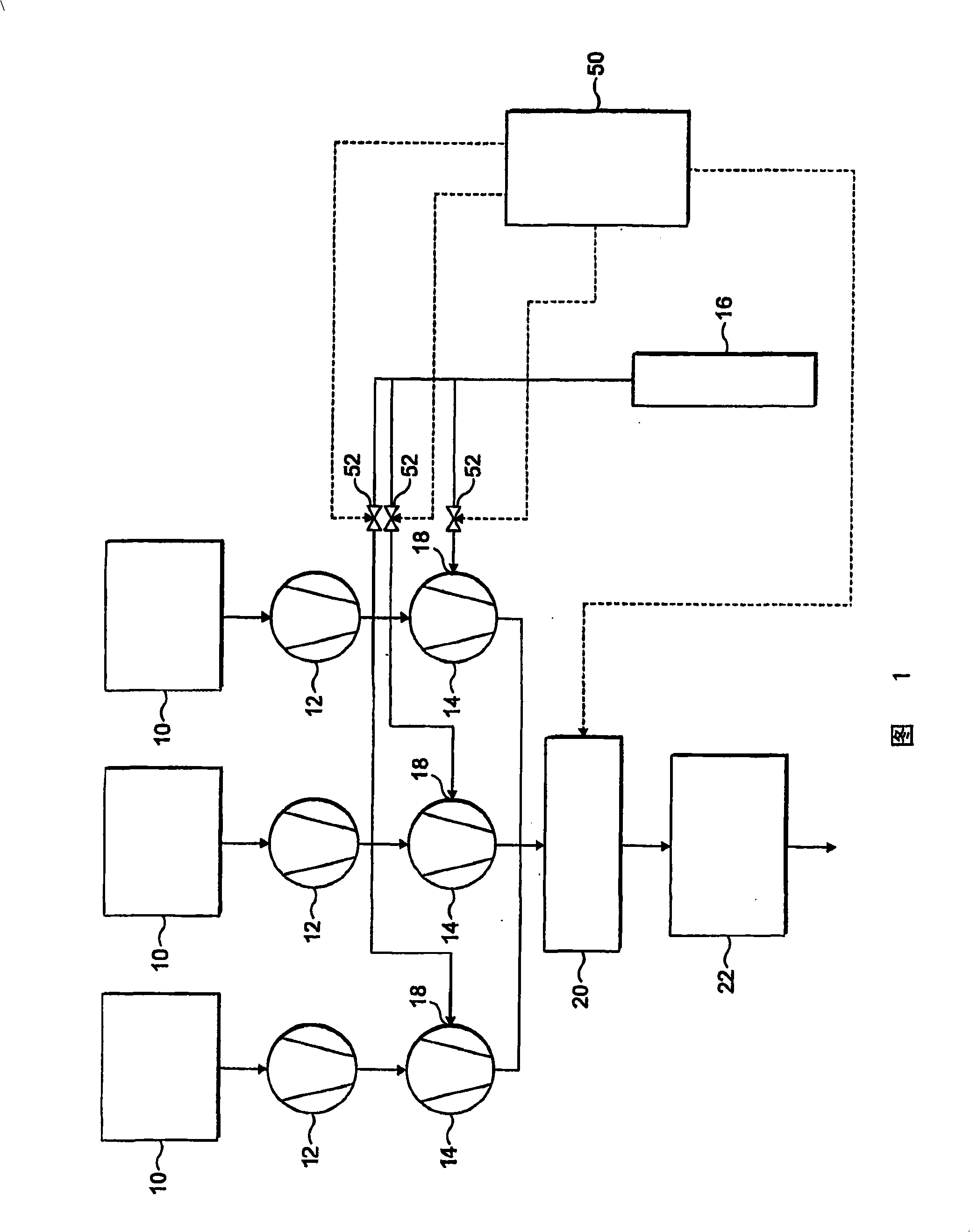

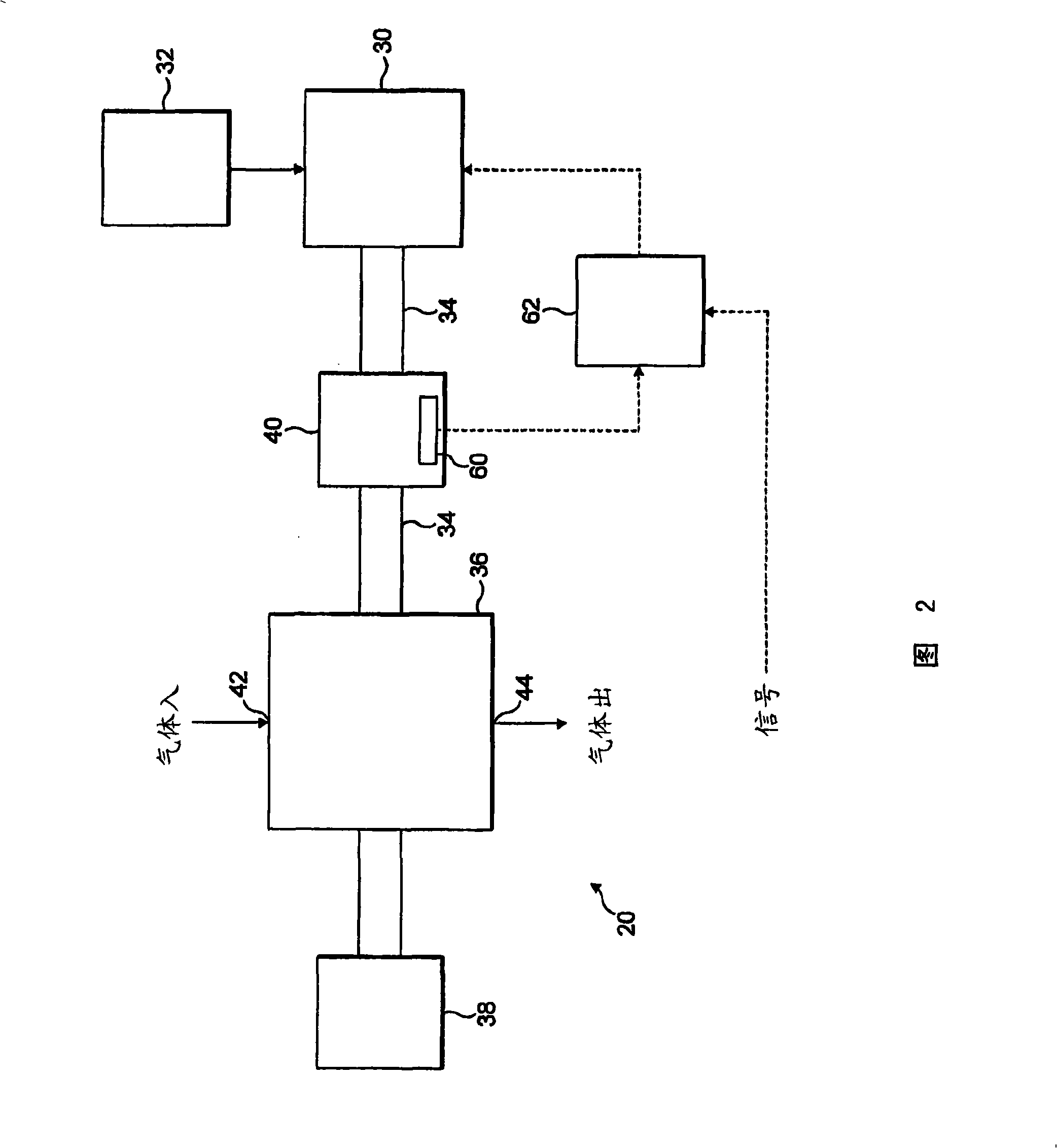

[0029] Referring first to FIG. 1, a processing tool includes a plurality of processing chambers 10, each for processing, for example, semiconductor devices, flat panel displays, or solar panel devices. Each processing chamber 10 receives various process gases for performing processing within the chamber 10 . For example, boron trichloride and chlorine may be provided for performing metal etch processes, ammonia and dichlorosilane may be provided for LPCVD processes, and sources of hydrogen bromide and chlorine for polysilicon etching. The process tool controls the supply of process gas to chamber 10 by providing control signals to valves and other flow control devices (not shown) for controlling the rate at which process gas is supplied to the chamber.

[0030] Exhaust gas is drawn from the outlet of each chamber 10 by a corresponding pump system. During processing within the chamber 10, only a portion of the process gas will be consumed, so the exhaust gas will contain a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com