Rubber composition for tyre belt layer and tyre prepared from the composition

A rubber composition and belt layer technology, which is applied to special tires, tire parts, rolling resistance optimization, etc., can solve problems such as driving difficulties and large changes in tire physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0111] [Manufacturing example: Manufacture of rubber composition]

[0112] Rubber compositions for tire belts according to Examples and Comparative Examples were produced using the compositions in Table 1 below. The rubber composition is produced according to the usual method for producing rubber compositions.

[0113] 【Table 1】

[0114]

[0115] (1) Natural rubber: RSS#3. Contains 25.5 parts by weight of TDAE oil based on 100 parts by weight of rubber.

[0116] (2) Carbon black: nitrogen adsorption specific surface area is 160m 2 / g, DBP (n-dibutyl phthalate) oil absorption is 210cc / 100g.

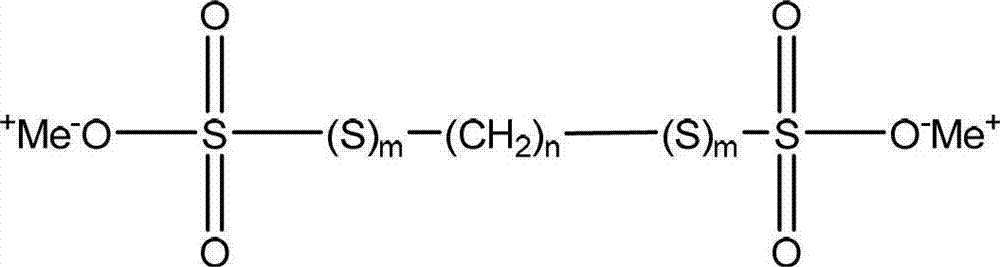

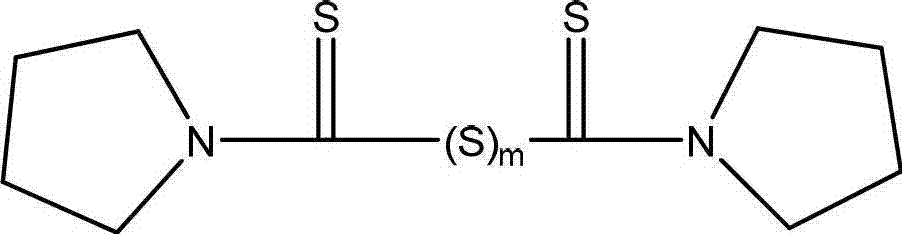

[0117] (3) Surface-treated aramid short fibers: a compound represented by the above chemical formula 1 (Me is Na , m is 1, n is 6) dihydrate 7.0 parts by weight and the compound represented by the above chemical formula 6 (R 1 and R 2 is hydrogen, m is 2) 6.5 parts by weight for surface treatment.

experiment example

[0118] [Experimental example: Measurement of physical properties of manufactured rubber composition]

[0119] Table 2 shows the physical properties of the rubber test pieces produced in the above Examples and Comparative Examples.

[0120]-100% modulus and elongation were measured according to the ISO37 standard.

[0121] -tanδ was measured by RDS (Rheo Dynamic Spectroscopy).

[0122] 【Table 2】

[0123]

[0124] Referring to the above Table 2, compared with the comparative example, the initial modulus of the example including the surface-treated aramid staple fiber was improved, and the heat generation was suppressed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption specific surface area | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com