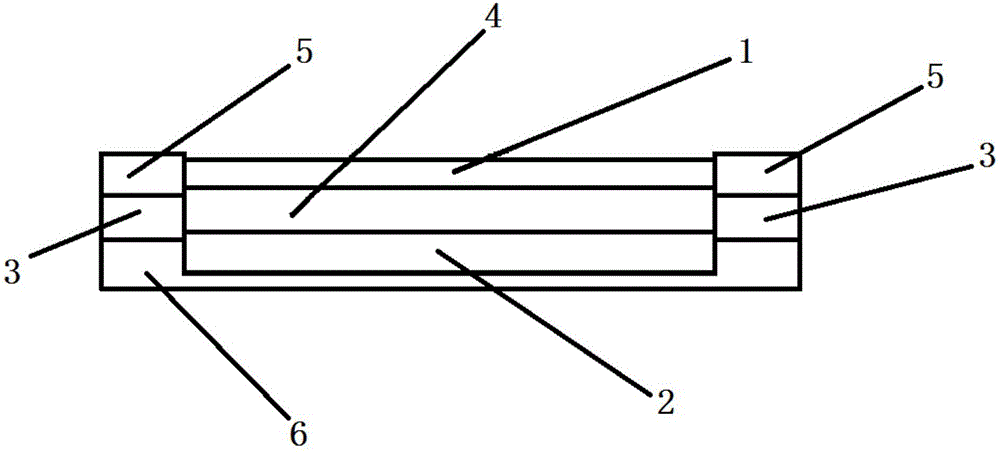

Full-lamination touch display screen with middle frame, manufacturing method thereof and touch device

A touch display, full-fit technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of time-consuming and laborious, high product cost, inapplicability, etc. , The effect of reducing the reflectivity and increasing the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for preparing a full-fit touch display screen with a middle frame. A middle frame is set between the display screen and the touch panel, and a hot-melt adhesive film is spread between the display screen and the touch panel in the middle frame. The lamination equipment is heated and fixed after lamination. The upper surface temperature of the hot-melt adhesive layer is 65°C during lamination, and the lower surface temperature of the hot-melt adhesive layer is 60°C during lamination. Lamination is performed for 5 minutes to obtain a full lamination contact with a middle frame. control display.

Embodiment 2

[0069] A method for preparing a full-fit touch display screen with a middle frame. A middle frame is set between the display screen and the touch panel, and a hot-melt adhesive film is spread between the display screen and the touch panel in the middle frame. The bonding equipment is heated and fixed after pressing. The temperature of the upper surface of the hot melt adhesive layer is 70°C during pressing, and the temperature of the lower surface of the hot melt adhesive layer is 65°C during pressing. Pressing for 1 minute, a full-fitting contact with a middle frame is obtained. control display.

Embodiment 3

[0071] A method for preparing a full-fit touch display screen with a middle frame. A middle frame is set between the display screen and the touch panel, and a hot-melt adhesive film is spread between the display screen and the touch panel in the middle frame. The lamination equipment is heated and fixed after lamination. The upper surface temperature of the hot melt adhesive layer is 68°C during lamination, and the lower surface temperature of the hot melt adhesive layer is 63°C during lamination, and the lamination lasts for 4 minutes;

[0072] Carry out defoaming with defoaming machine then, defoaming pressure is 0.1kPa, and defoaming time is 10min;

[0073] Then use a UV curing machine for UV light curing, and the UV light energy density is 800MJ / cm 2 , the UV curing time is 30s, and a fully laminated touch display screen with a middle frame is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com