Method and facility for adhesion of transverse joints of lining hoses for pipeline in-situ repair

A technology of in-situ repair and bonding method, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve problems such as construction failure and hose breakage, and achieve the effect of stable mechanical properties and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

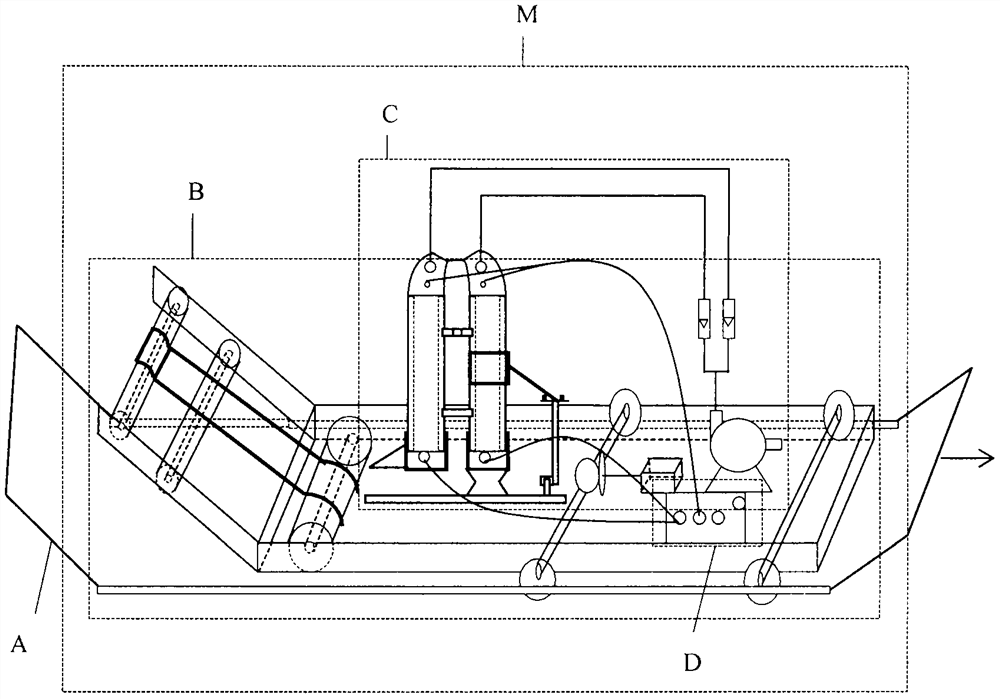

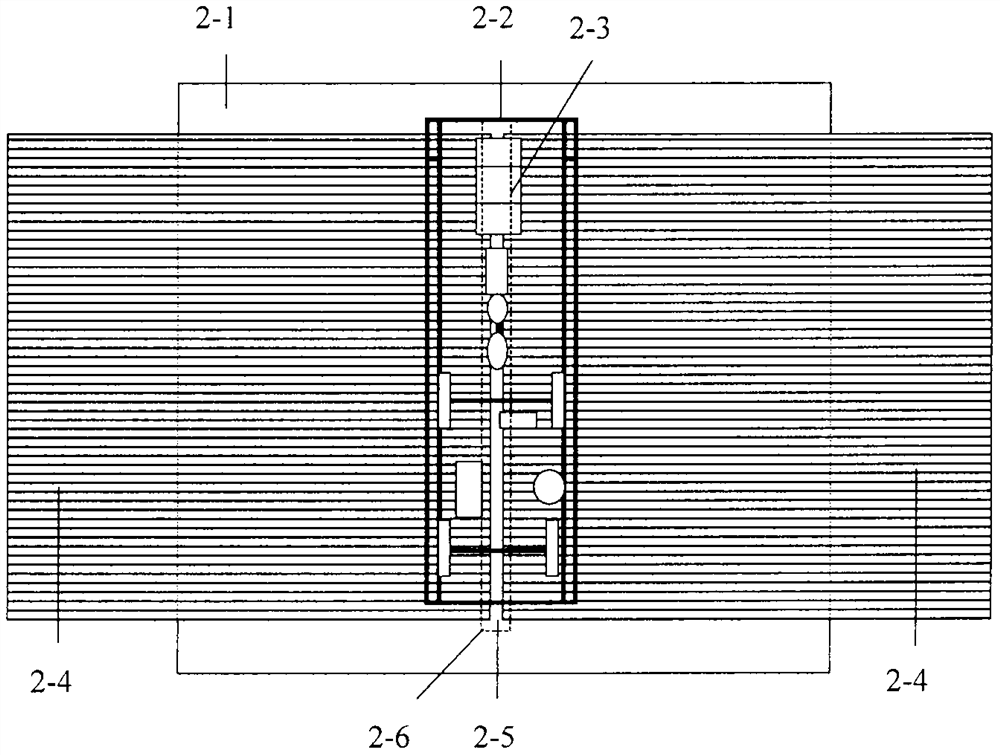

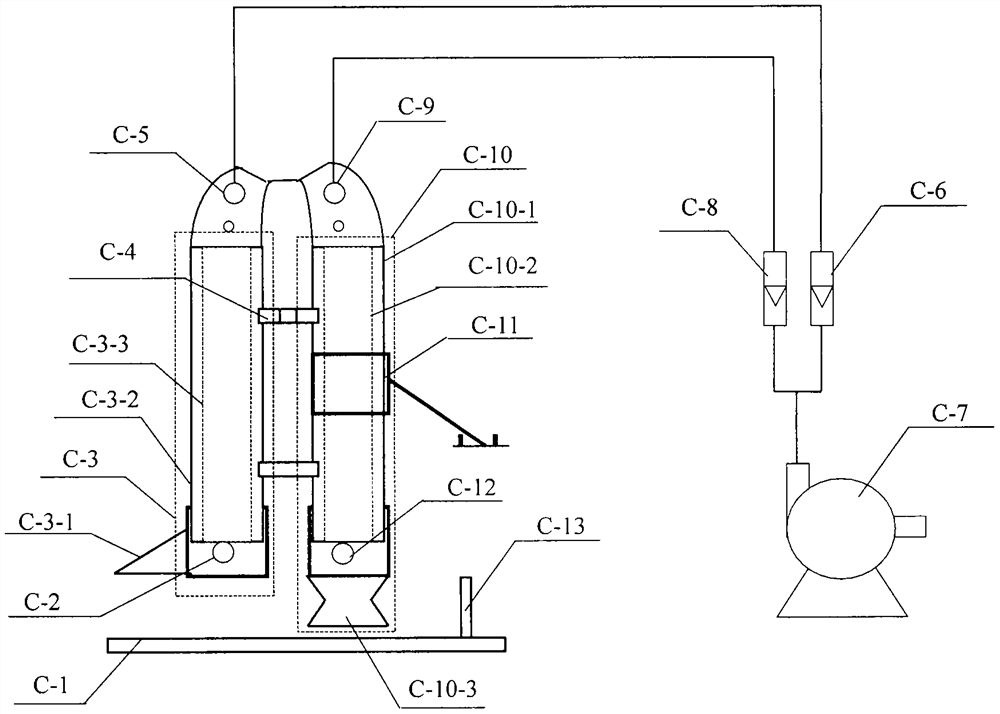

[0024] figure 1 It is a diagram of the horizontal joint heat compounding equipment of the present invention; figure 2 It is a top view of the hose base layer docking and horizontal joint heat compounding equipment of the present invention; image 3 It is the equipment heating device figure of the present invention; Figure 4 yes image 3 left view of Figure 5 It is a top view of the heating box of the equipment of the present invention; Image 6 It is the front view of the heating box of the equipment of the present invention; Figure 7 It is the traveling device diagram of the equipment of the present invention.

[0025] A preparation process for in-situ repair of double-layer hose transverse joints, characterized in that the preparation process of the hose transverse joints is as follows:

[0026] S1: Pass the inner sealing strip (2-6) through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com