A semi-automatic flexible battery module film sticking device

A flexible battery and film sticking device technology, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problem of easy scratches on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

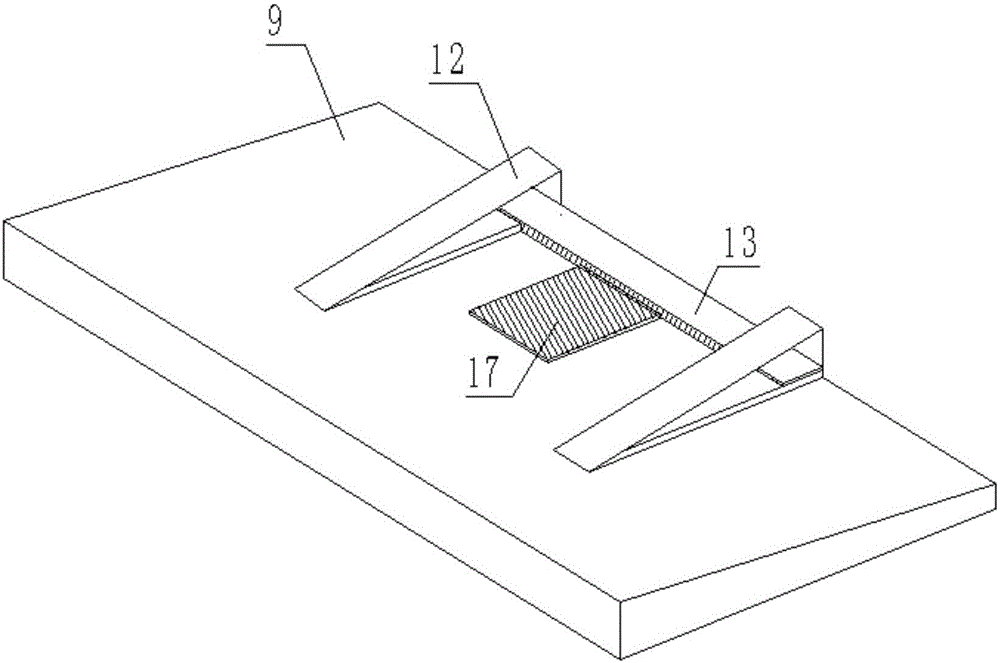

[0023] The structure of the semi-automatic flexible battery module film sticking device is as described above, the difference is that the structure of the fixed rubber shaft 6 is different, and the other structures are the same. Such as Figure 4As shown, the fixed rubber shaft 6 is divided into two shorter first rubber shafts 15 and second rubber shafts 16 , and the first rubber shaft 15 and the second rubber shaft 16 are fixed below the movable rubber shaft 5 . The sum of the lengths of the first rubber shaft 15 and the second rubber shaft 16 is less than the length of the movable rubber shaft 5, so that the contact area between the adhesive surface of the PE film and the rubber shaft can be reduced. Because the PE film is attached to the flexible battery assembly after being extruded by the fixed rubber shaft 6 and the movable rubber shaft 5, the cleanliness of the PE film must be considered to reduce dust adhesion on the surface of the flexible battery assembly. The conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com