Differential long core head pipe drawing method

A technology of pipe drawing and core head, applied in metal drawing forming tools, metal wire drawing, metal processing equipment, etc., can solve the problem of easily scratched inner surface, cumbersome drawing process of moving long mandrel, and limitation of process pipe specifications. and other problems to achieve the effect of solving surface scratches, reducing the pulling force and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) The material is 2024 aluminum alloy, the diameter is φ180mm, the wall thickness is 10mm, and the length is 3m. It needs to be drawn with a core to form a pipe with a diameter of φ176mm, a wall thickness of 8.5mm, and a length of 3.46m;

[0022] 2) First make the drawing head, and perform local diameter reduction processing on the pipe head to form a diameter reduction section with a diameter of φ174mm and a length of about 100mm;

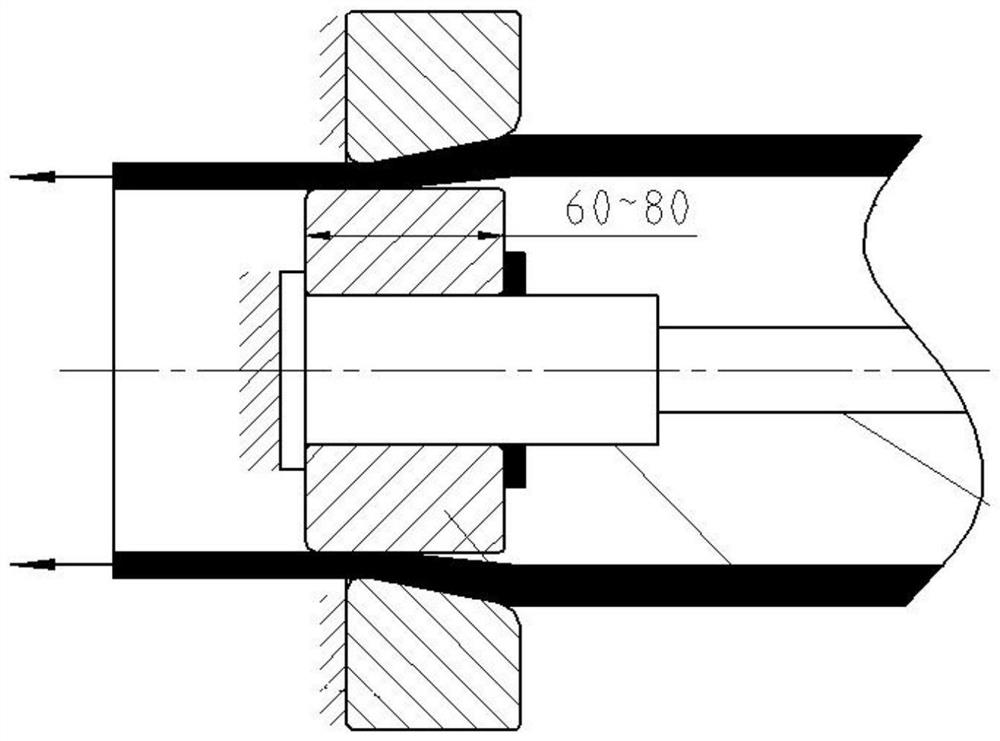

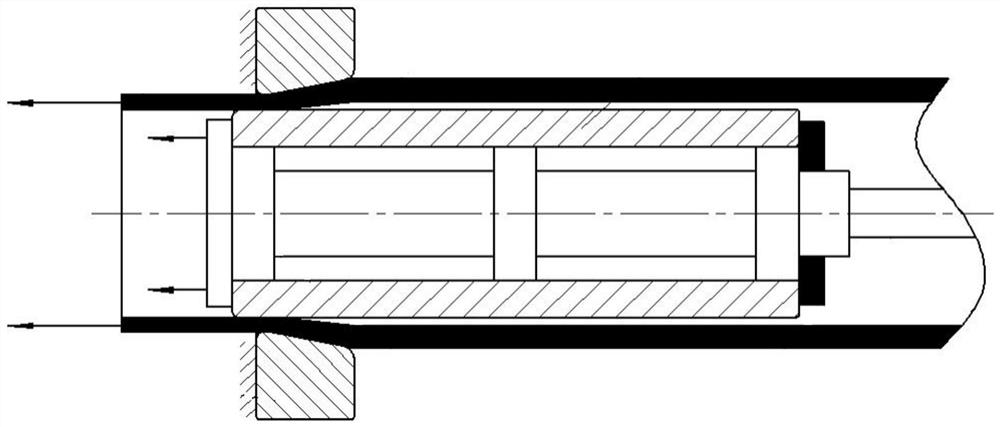

[0023] 3) Choose a long core head with a working belt length of 450mm and a diameter of φ159mm to install on the core head seat, the core head seat is installed on the core head pull rod, and the core head is fixed with a lock nut so that it is integrated with the pull rod;

[0024] 4) Install the φ176mm outer mold into the mold base;

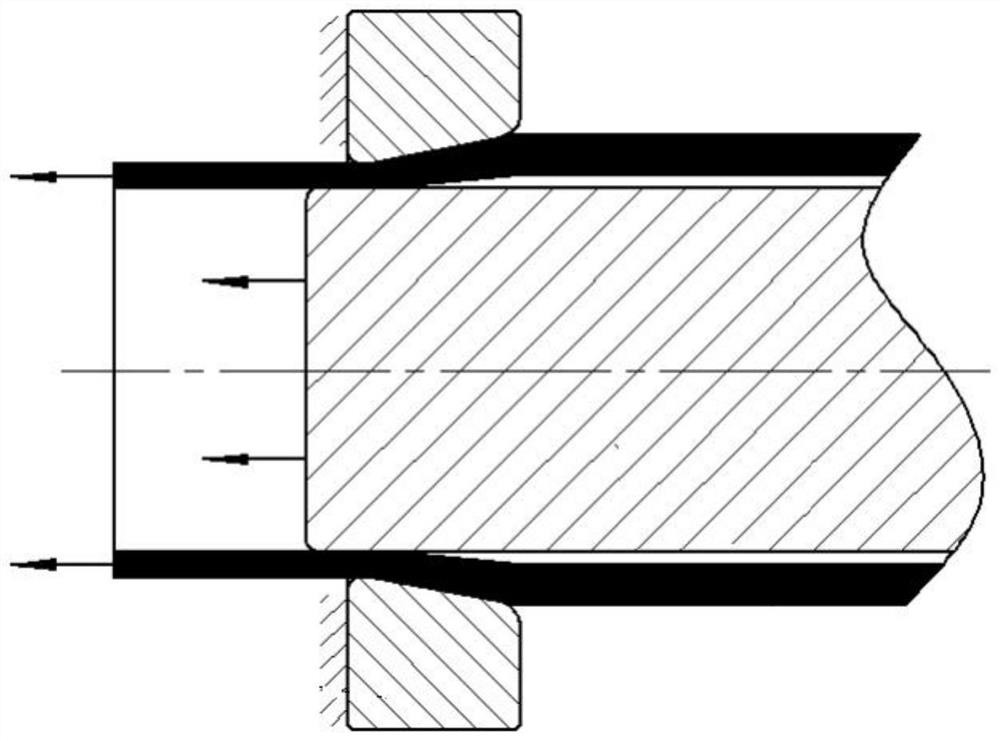

[0025] 5) Lubricate the working cone of the outer mold and the core head, the working belt and the inner and outer surfaces of the pipe, requiring uniform lubrication and moderate thickness of the oil film;...

Embodiment 2

[0032] The drawing process is the same as in Example 1, except that the material is 7475 aluminum alloy, the diameter is φ30mm, the wall thickness is 1.5mm, and the length is 8m. 1.3mm, length of 10m pipe.

[0033] Use a long core head with a diameter of φ24.9mm and a working belt length of 3.3m, and the moving speed ratio of the pipe and the long core head is 3:1.

[0034] After drawing, the inner and outer surfaces of the pipe are smooth, without scratches, and the size meets the requirements.

Embodiment 3

[0036] The drawing process is the same as in Example 1, except that the material is 316 stainless steel, the diameter is φ70mm, the wall thickness is 5mm, and the length is 5m. 6m pipe.

[0037] Use a long core head with a diameter of φ58.6mm and a working belt length of 3m, and the moving speed ratio of the pipe and the long core head is 2:1.

[0038] After drawing, the inner and outer surfaces of the pipe are smooth, without scratches, and the size meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com