A kind of led powder spraying method

A technology of powder spraying and powder spraying machine, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of unevenness, high operation efficiency, and large amount of powder spraying, to ensure consistency, improve accuracy, and satisfy color temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

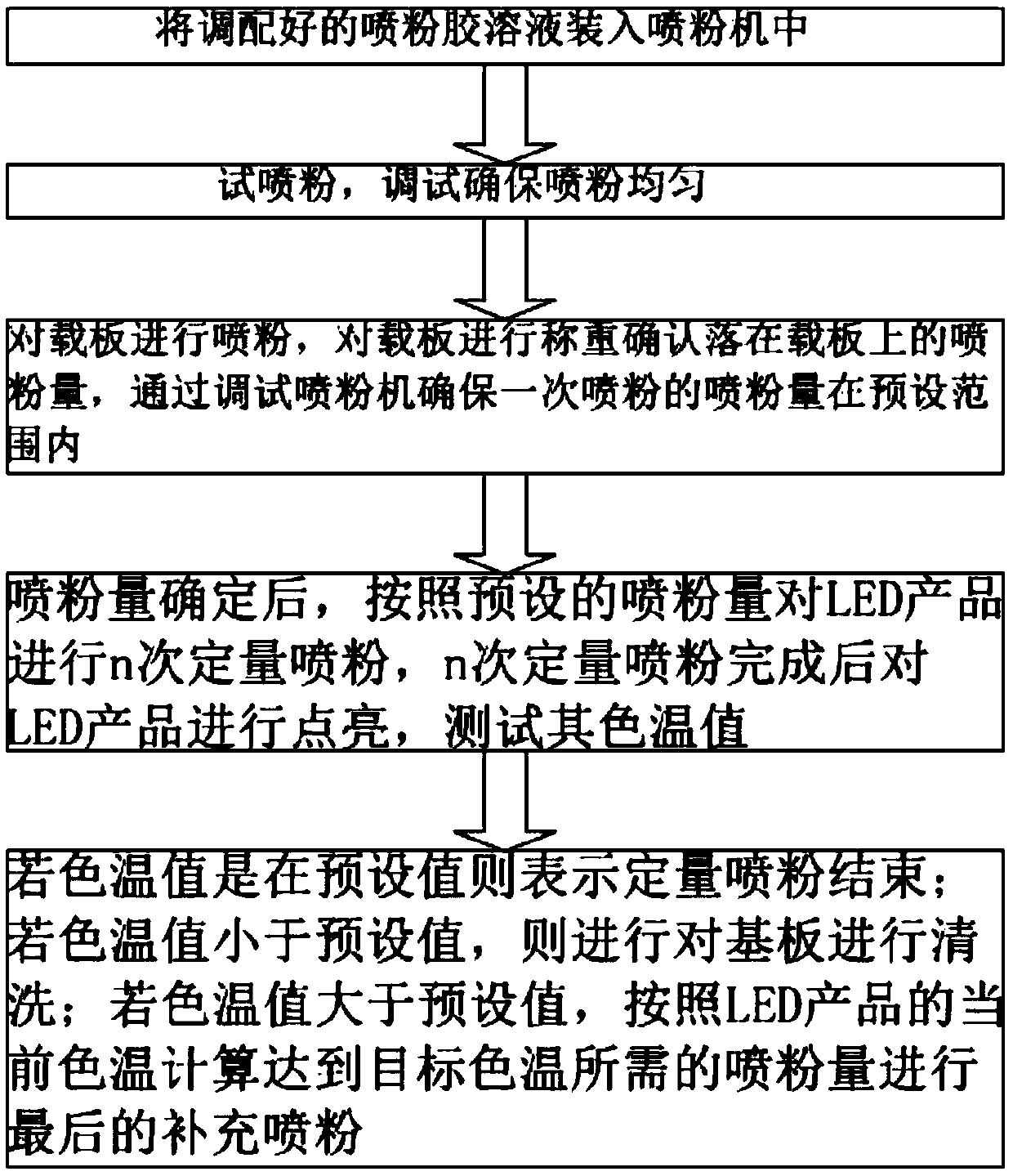

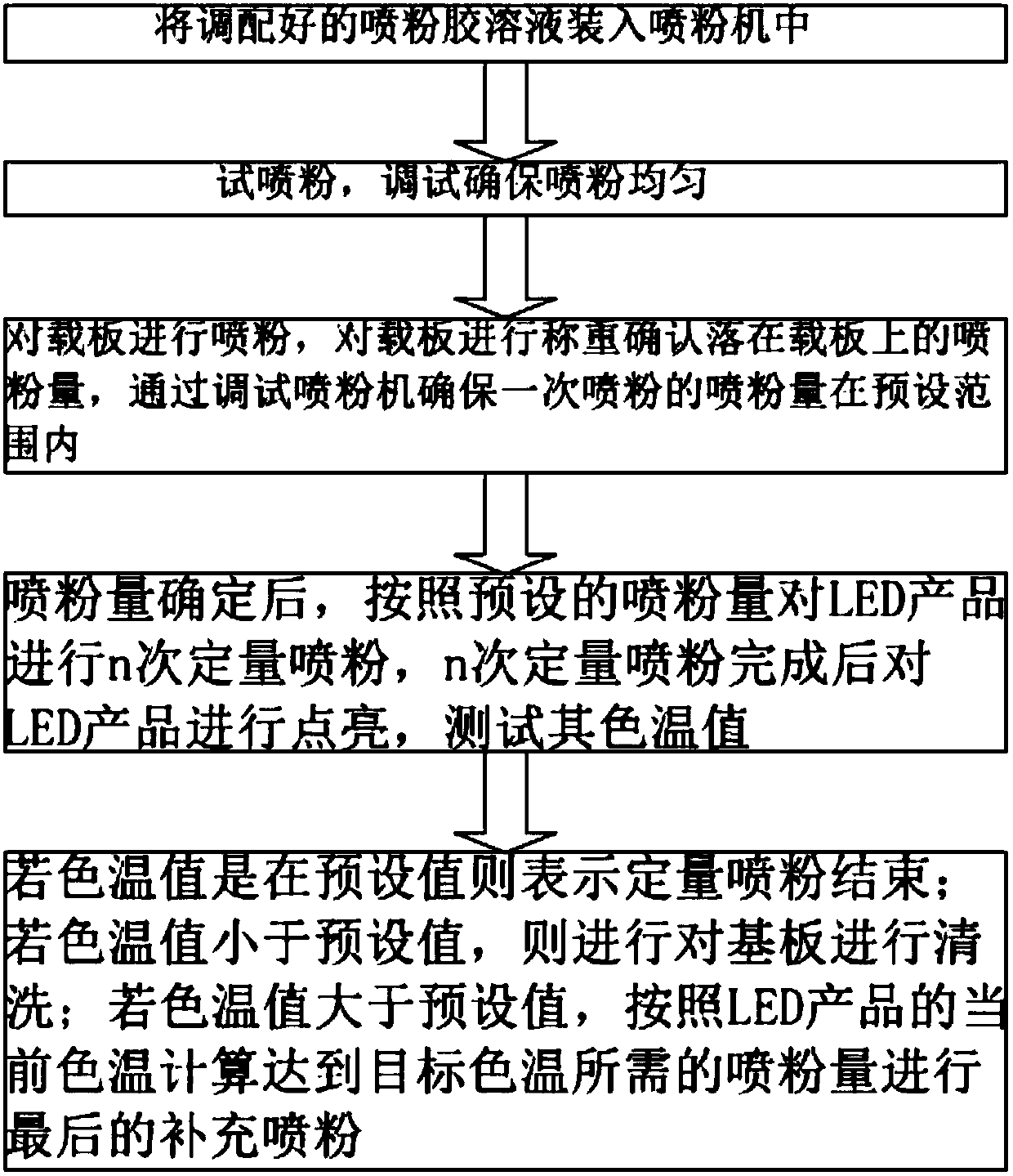

Embodiment 1

[0031] A kind of LED dusting method, comprises the following steps:

[0032] (1) Parameter setting of powder spraying machine: click to open the setting page, and ensure that the following important parameters of powder spraying are set correctly:

[0033] Heating (Heater): on (open);

[0034] Movement interval (ptich-monement): X: 5mm; Y: 5mm;

[0035] Moving speed (moving-speed): 50mm / sec;

[0036] Origin coordinates (postion 1): X: 25mm; Y: 35mm; Z: 88mm;

[0037] Powder spraying mode (mode selection): Pulse (pulse mode);

[0038] T4: 13.5ms (this value can be fine-tuned during the powder replenishment stage);

[0039] Dust spray area range (Size) setting (can be adjusted according to the actual powder spray situation): spray one piece: X 75mm; Y150mm; spray two pieces: X 145mm; Y 150mm; The area of the two pieces is 145*150mm;

[0040] (2) Mix powder-spraying glue solution: mix glue, fluorescent powder and diluent in a ratio of (1:1:3), then pour into a centrifugal...

Embodiment 2

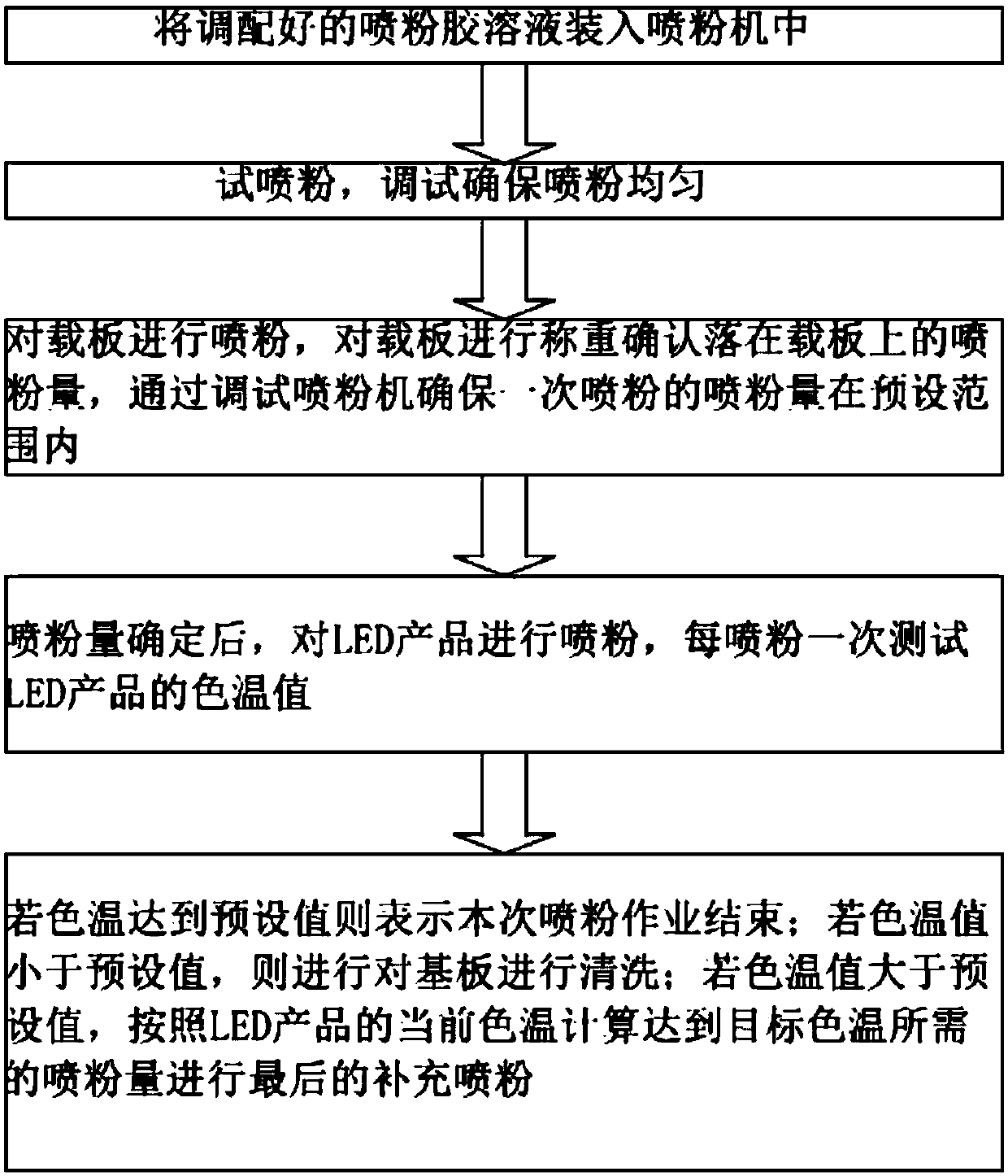

[0061] Such as figure 2 As shown, the difference from Example 1 is that after the amount of powder spraying is determined, the LED product is sprayed with powder, and the color temperature value of the LED product is tested every time the powder is sprayed. If the color temperature is within the preset value range, it means that the powder sprayed this time The operation is over; if the color temperature value is less than the preset value, the substrate will be cleaned; if the color temperature value is greater than the preset value, the final supplementary powder spraying will be carried out according to the current color temperature of the LED product to calculate the amount of powder required to achieve the target color temperature.

[0062] At the same time, in order to prevent excessive supplementary powder spraying, if the color temperature value is greater than the preset value, the final supplementary powder spraying steps include: if the color temperature value is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com