Printed circuit board manufacturing method

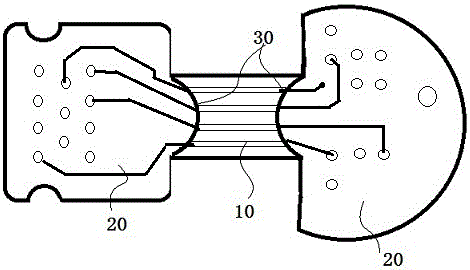

A production method and circuit board technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve problems such as difficult production, low yield rate, and easy breakage, so as to solve the problem of unstable connection and improve the use of Longevity, the effect of avoiding the fracture of the bending area and falling parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

[0018] The circuit board manufacturing method of the present invention comprises the following seven steps:

[0019] (1) Design the circuit graphics, drilling and shape data. In the circuit graphic design, only the connection circuit is designed in the part corresponding to the bending area, and the pads for welding devices are not set, that is, only the connection line is designed in the bending area and no electronic components are designed. Devices, arrange the electronic devices in the non-bending area of the hard copper clad laminate and the copper clad soft laminate. And output image negatives according to the designed graphics. In addition, in the shape data design, the edge of the hard board corresponding to the junction of the non-bending area and the bending area needs to be designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com