A kind of tobacco storage leaf warming and humidifying machine and tobacco storage leaf warming and humidifying method

A technology for increasing temperature, humidifying and storing leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of a lot of capital and energy consumption, uneven moisture inside and outside the leaves, and easy loss of moisture in the leaves, so as to save the cost of outsourcing equipment. , The effect of reducing moisture volatilization and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the present invention will be clearly and completely described below in conjunction with the drawings in the present invention.

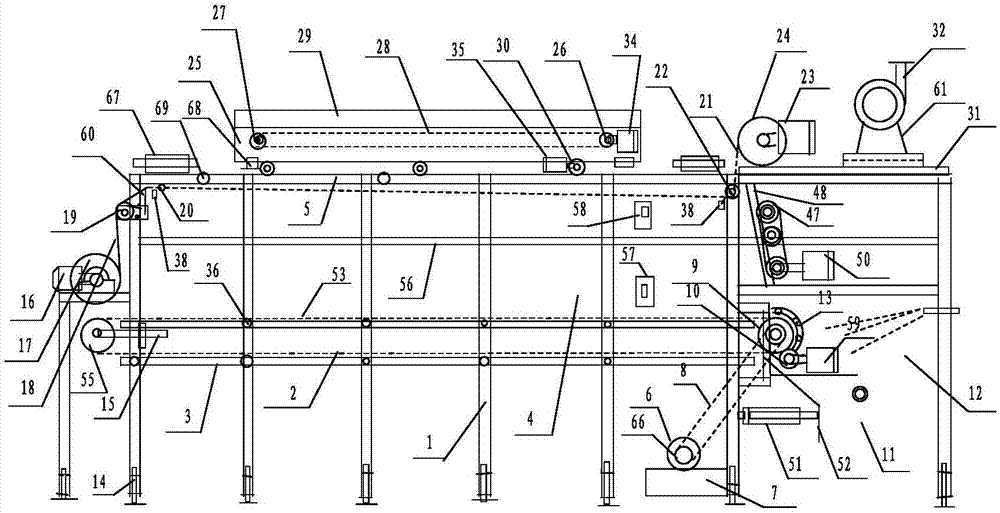

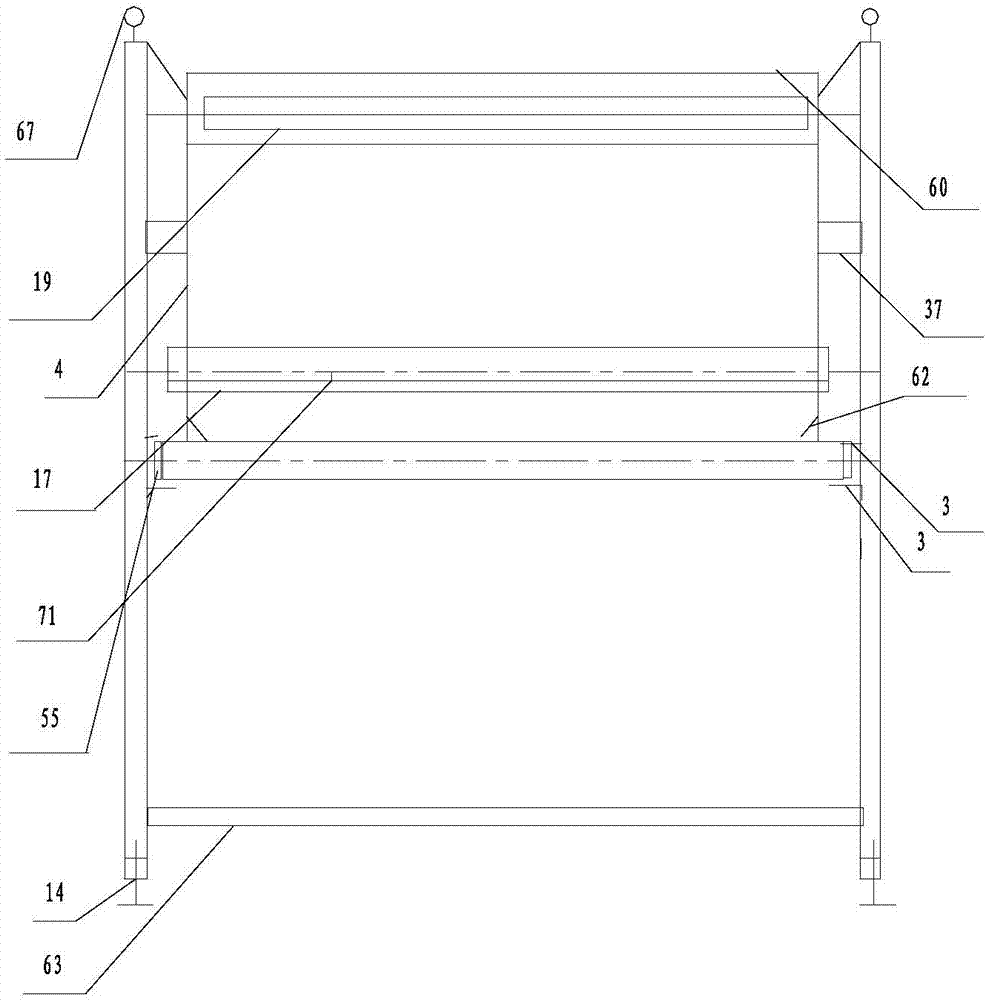

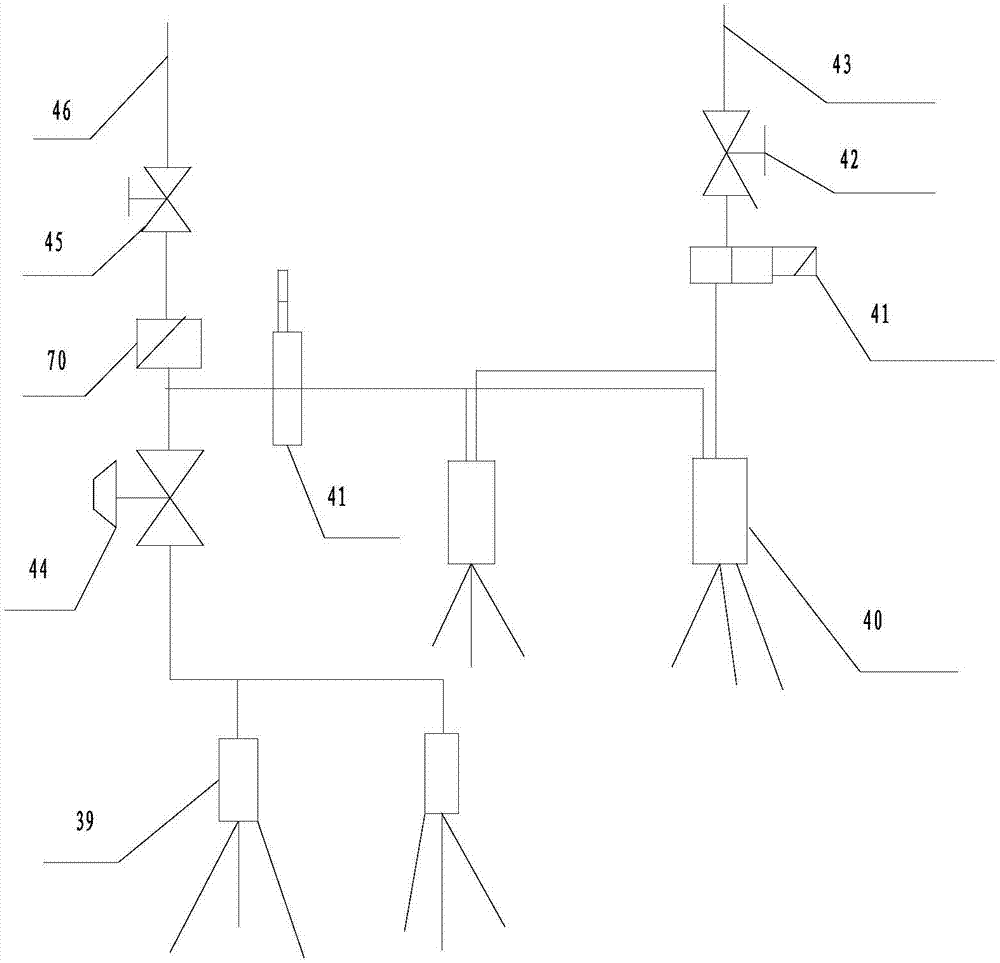

[0031] like figure 1 As shown, one embodiment of the present invention is used in the tobacco leaf storage warming and humidifying machine including a frame 1, a box wall panel 4 located on the frame 1, a cloth traveling vehicle and a covering device, and a heating and humidifying device.

[0032] The whole equipment is rectangular. The frame 1 is made of I-shaped carbon steel. The frame 1 is also provided with a chain track 3. The chain driving wheel 9 and the chain driven wheel 55 are respectively arranged on both sides of the frame 1. The chain driving wheel 9 and the The chain driven wheels 55 are connected by the winged chain 2, and the winged chain 2 is held up by the chain track 3, so that the winged chain 2 can move on the chain track 3 to prevent it from sinking. The winged chain 2 is provided with a botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com