Washable polylactic acid fiber material quilt and manufacturing process thereof

A polylactic acid fiber and production process technology, applied in knitting, sheets, roughening and other directions, can solve the problems of incomplete cleaning and difficult quilt cleaning, and achieve the effect of good environmental protection and maintaining fluffy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

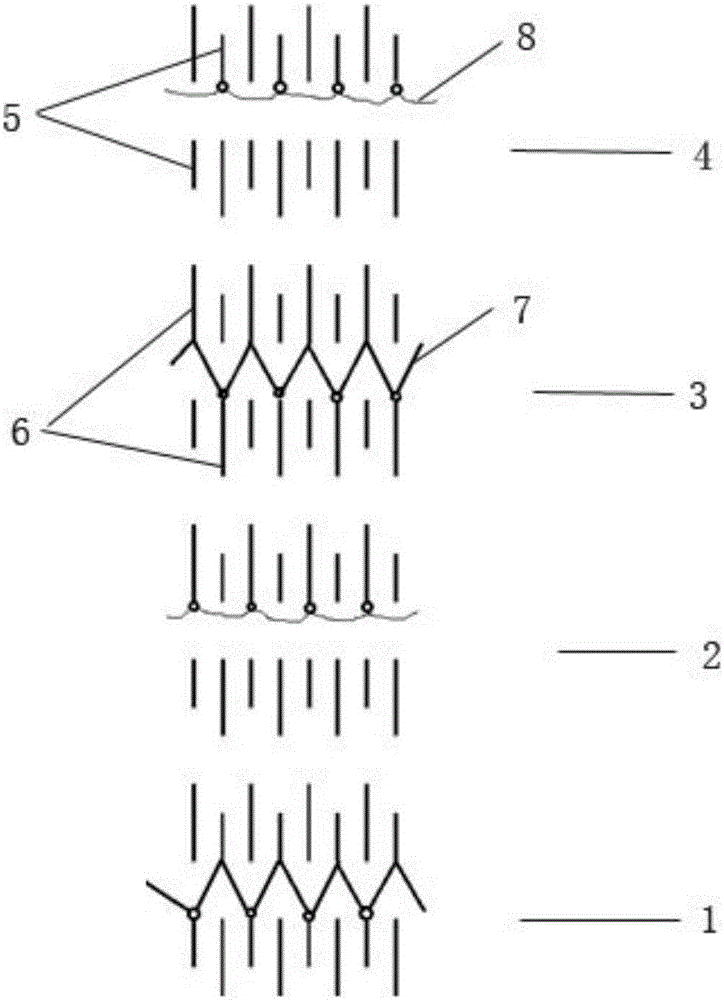

[0034] Polylactic acid fiber has a high elastic recovery rate of 93% (the elastic recovery rate of cotton fiber is about 51%). This feature can ensure that the fiber maintains a high bulkiness when used as a filler, and the thermal performance is improved. At the same time, the polylactic acid fiber has a high degree of crimp (about 16.5 pieces / 25mm), which is beneficial to the entanglement between fibers. The quilt of the present invention is obtained by weaving the polylactic acid quilt cover and making the inner filler of the quilt respectively by using pure polylactic acid fibers as raw materials.

[0035] The washable polylactic acid fiber material quilt of the present invention comprises a quilt cover and a quilt filler;

[0036] The quilt cover uses polylactic acid yarn weft-knitted fabric as the quilt layer, and polylactic acid filament as the surface of the quilt cover facing the same fluff layer; the specification of the polylactic acid yarn is 40s; the specification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com