Center shaft for disc filter

A technology of disc filter and central shaft, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of poor strength and rigidity of the central shaft, occupy a large space, reduce energy consumption, etc., and achieve strength and rigidity Improvement, beautiful appearance, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

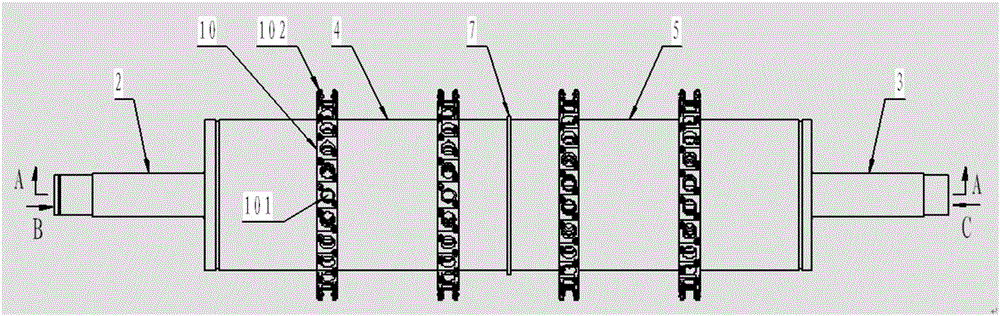

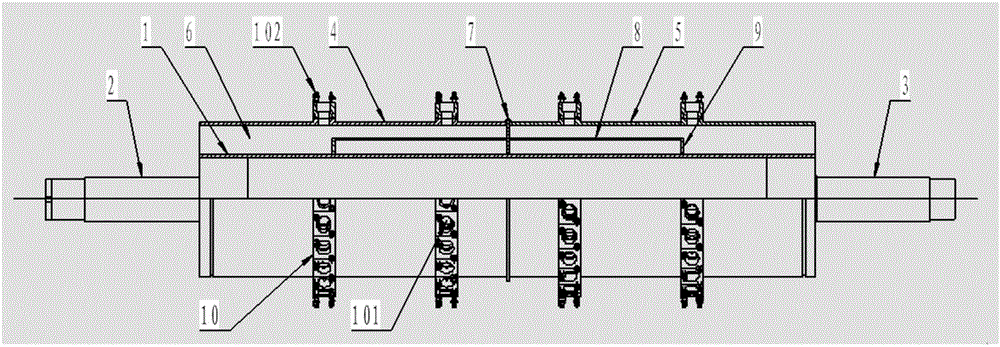

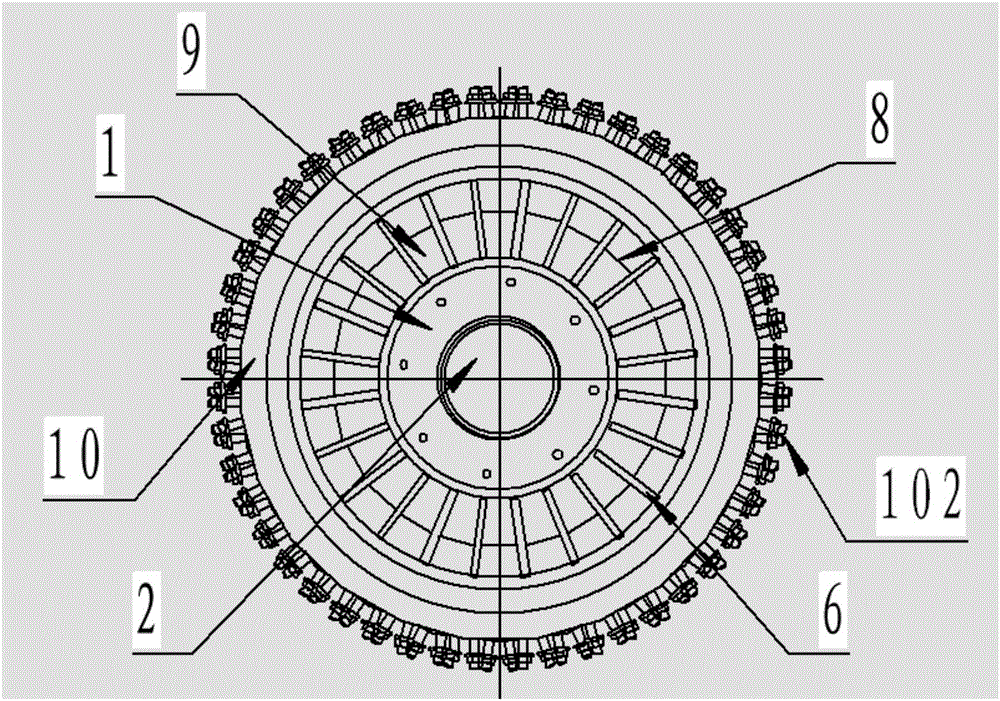

[0025] The center of both ends of the central support cylinder 1 is respectively provided with a transmission shaft 2 and a support shaft 3, and the outer periphery of the central support cylinder 1 is provided with an external cylinder composed of a first external cylinder 4 and a second external cylinder 5, the first external Between the cylinder body 4 and the second external cylinder body 5, a middle partition 7 is arranged in the center corresponding to the outer periphery of the central support cylinder body 1, and at least two bracket sleeves 10 are respectively arranged on the outer peripheries of the first external cylinder body 4 and the second external cylinder body 5 , between the first outer cylinder 4 or the second outer cylinder 5 and the outer periphery of the central support cylinder 1, flow channel partitions 6 are evenly distributed, and a first blocking plate 8 is arranged between two adjacent flow channel partitions 6, and the second The length of an extern...

Embodiment 2

[0027] The structure of the bracket cover 10 is as follows: the bracket cover 10 is a regular n-gon, and each end face of the bracket cover 10 periphery is a rectangle, and the center of the rectangular end face is provided with a flow channel hole 101, and each flow channel hole 101 is connected to the corresponding Each flow passage with variable cross-section communicates with each other, and bolt assemblies 102 are arranged on the two diagonal corners of the rectangular end face.

Embodiment 3

[0029] The flow channel partitions 6 evenly distributed between the first outer cylinder 4 and the outer circumference of the central support cylinder 1 and the flow channels evenly distributed between the second outer cylinder 5 and the outer circumference of the central support cylinder 1 The separators 6 are arranged in a staggered manner, and the staggered angle is 180° / n. The said n is consistent with the value of the bracket cover 10 being a regular n-gon, and the said n is 10-70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com