Mold Positioning Sealing Device

A sealing device and casting mold technology, applied in foundry equipment, equipment for transporting casting molds, metal processing equipment, etc., can solve the problems of serious wear, poor sealing effect, and difficulty in ensuring the quality of castings, and achieve good economic benefits, improve quality, The effect of high mold clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

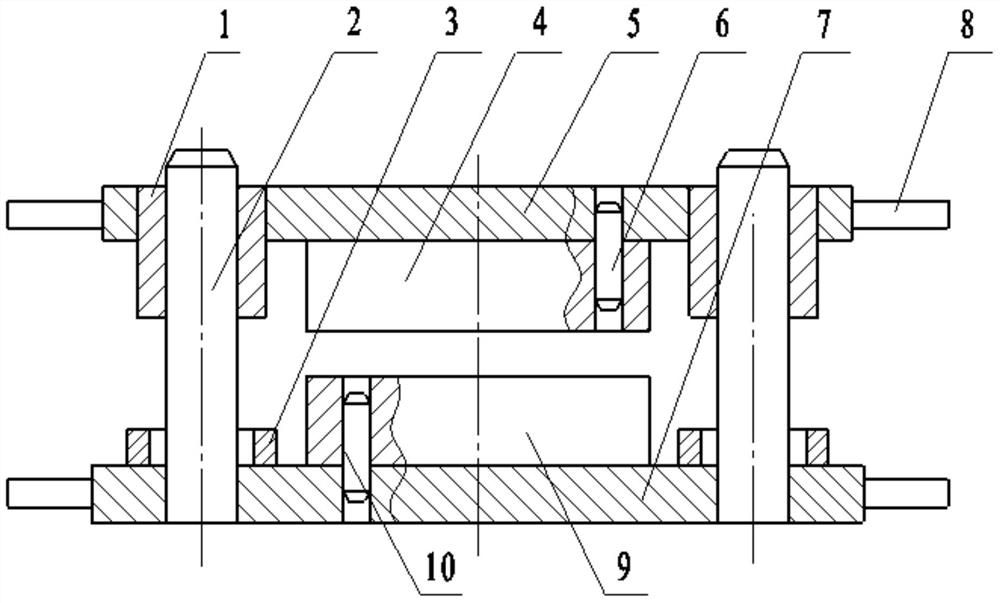

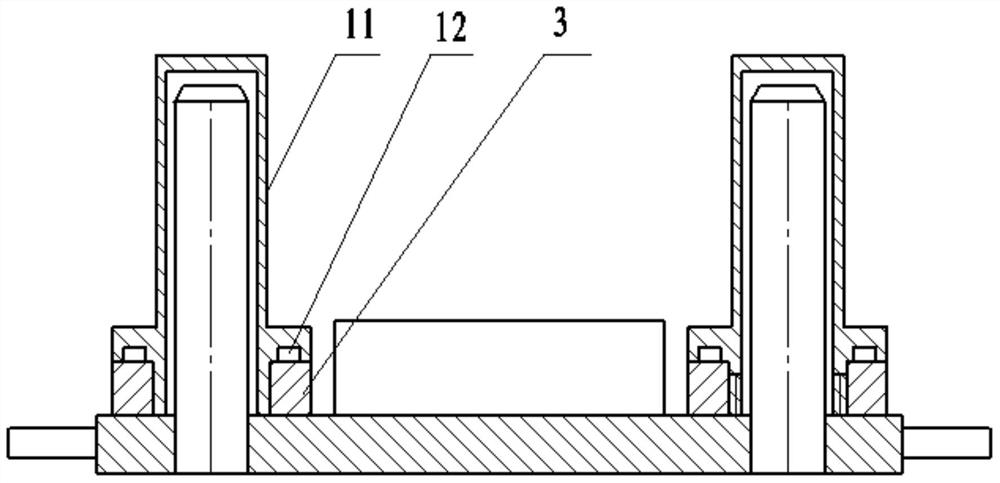

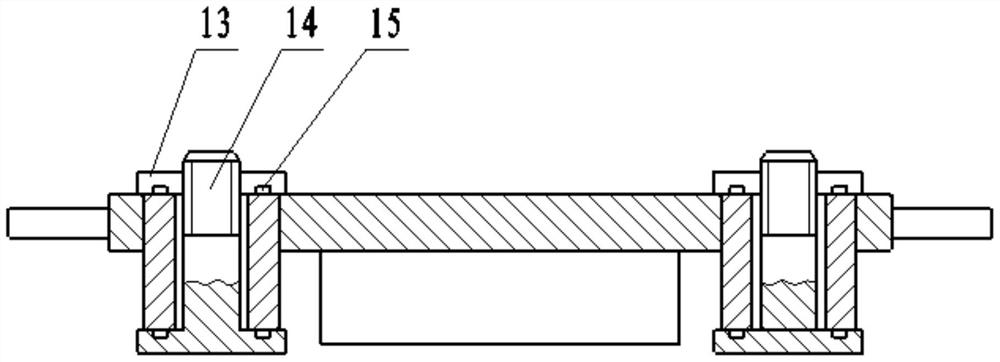

[0014] A casting mold positioning and sealing device according to the present invention, as shown in the accompanying drawings, it consists of a guide sleeve 1, a guide post 2, a guide post sealing nut 3, an upper die 4, an upper die plate 5, an upper die positioning pin 6, and a lower die plate 7 , lifting shaft 8, lower die 9, lower die positioning pin 10, guide post seal cover 11, guide post seal ring 12, guide sleeve seal nut 13, guide sleeve seal screw rod 14, guide sleeve seal ring 15. The guide sleeve 1 is connected with the upper template 5 through static fit, the guide post 2 is connected with the lower template 7 through static fit, the guide sleeve 1 is connected with the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com