A positionable sawing device

A technology of positioning device and sawing material, which is applied in the attachment device of sawing machine, metal sawing equipment, metal processing and other directions, can solve the problems of reducing the work efficiency of cutting workers and increasing the work intensity of cutting workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

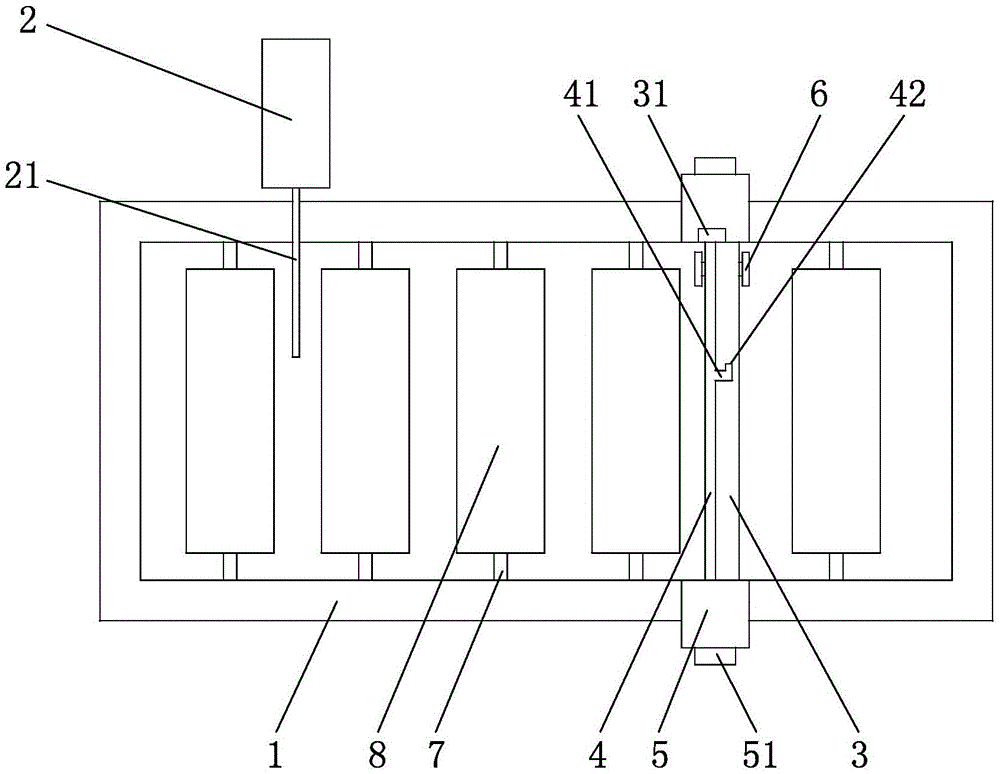

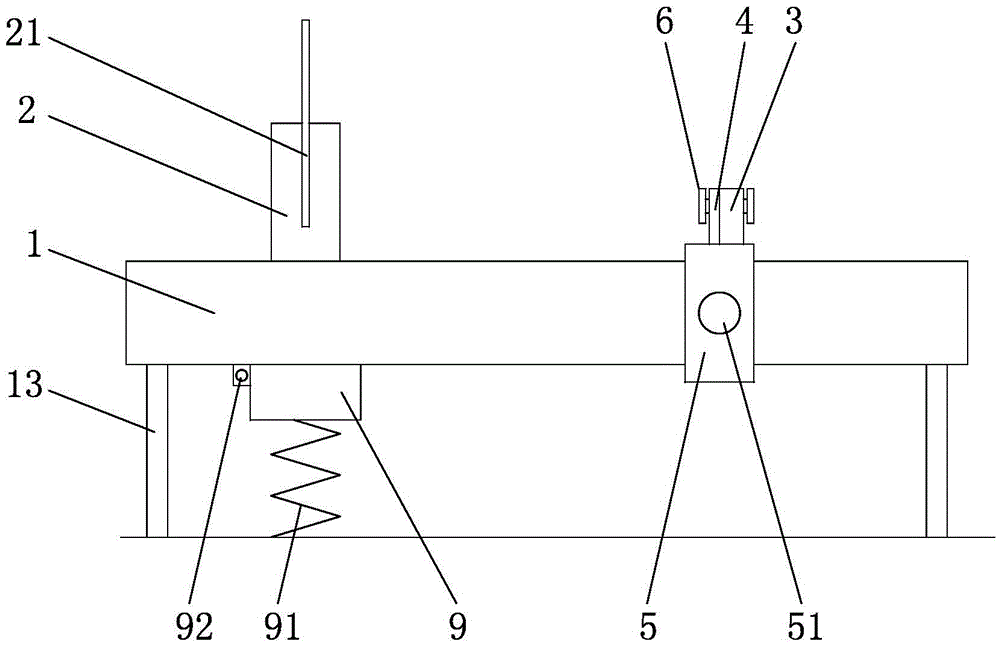

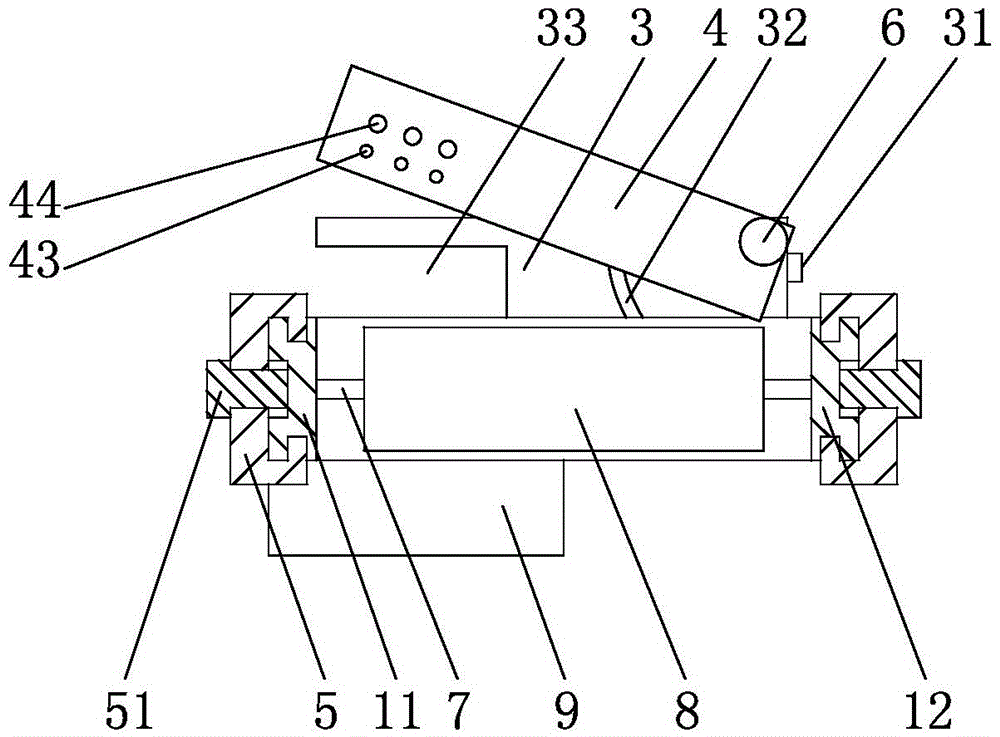

[0017] A positionable sawing device includes a sawing platform, a cutting device and a positioning device, the cutting device includes a cutting tool, and the cutting tool is correspondingly arranged above the sawing platform, and the cutting device and the positioning device are respectively It is arranged at both ends of the sawing platform, and the sawing platform includes two parallel beams, a connecting rod is arranged between the two beams, and a roller is sheathed on the connecting rod, and the positioning device includes an adjustment assembly, A positioning piece, a baffle plate and a first rotating shaft, the positioning piece is provided with a gap, the adjustment assembly is movably arranged on the beam, the positioning piece is fixed on the adjustment assembly, and the baffle plate is arranged on the positioning piece On one side of the baffle, the baffle is connected to the positioning member through the first rotating shaft, the positioning member is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com