An electric tensioning device and method for a tailstock of a digital distribution unit

A technology of elastic device and tailstock, which is applied in the direction of portable mobile devices, motor tools, manufacturing tools, etc., can solve the problems of easy knotting of coaxial cables, low work efficiency, and long time-consuming, etc., so as to facilitate follow-up maintenance management, Improved work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

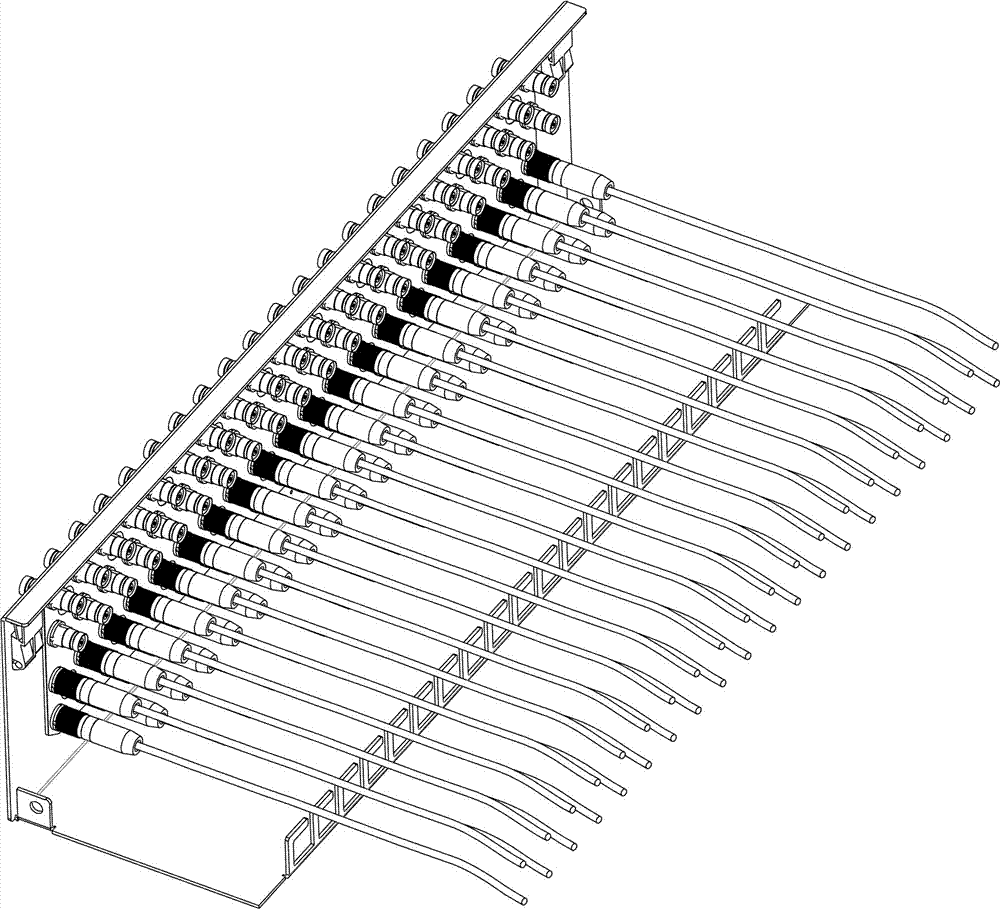

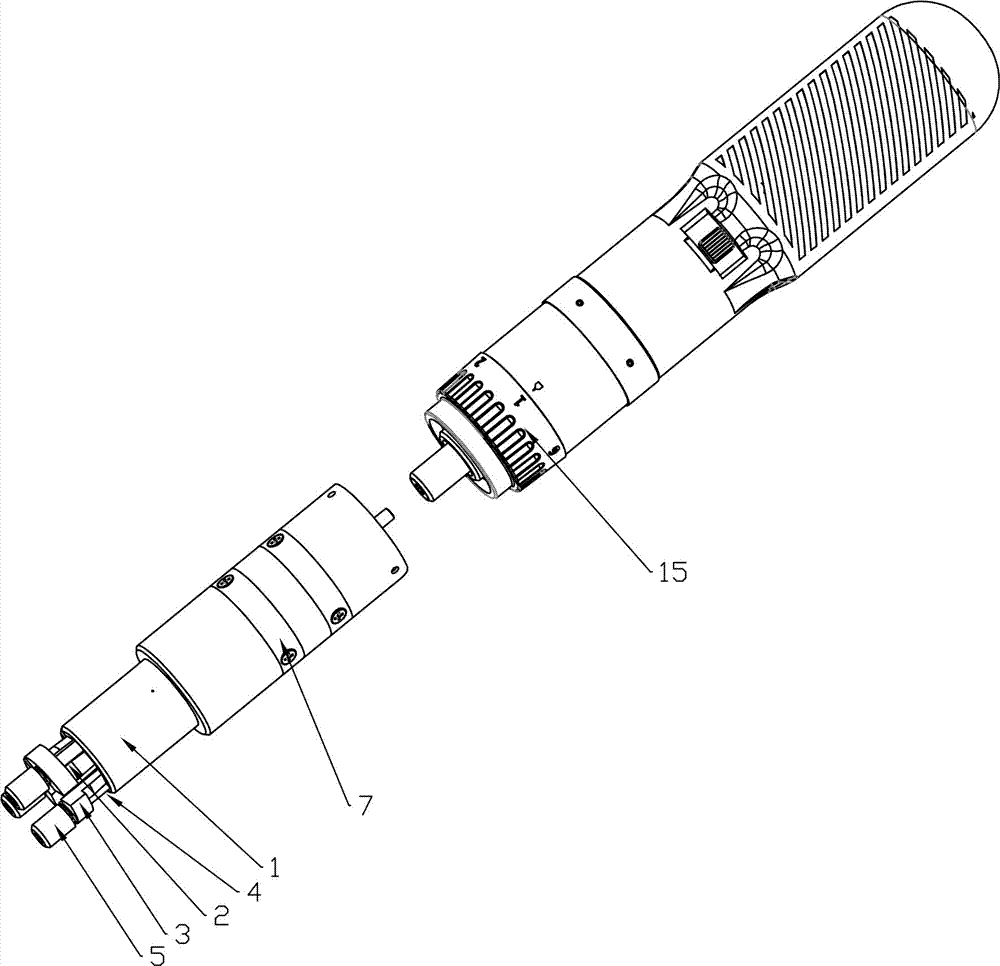

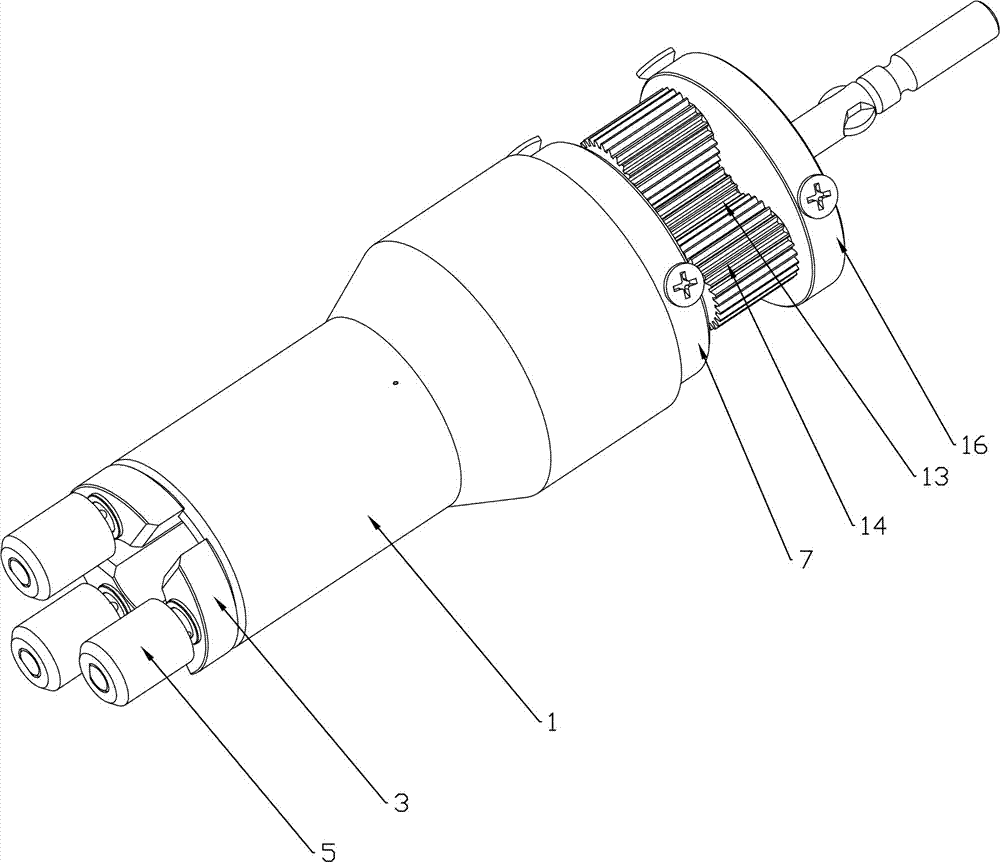

[0031] Such as Figure 2-6 As shown, an electric tensioning device for a tailstock of a digital distribution unit includes a clamping rotation mechanism and a driving mechanism, the clamping rotation mechanism includes a clamping adjustment mechanism and a rotation mechanism, and the clamping adjustment mechanism includes an outer sleeve 1, The outer sleeve 1 is provided with a collet 2 that can be expanded and tightened. The collet 2 is a hollow structure and has a hole suitable for the rear end of the tailstock. When unscrewing or tightening, the The positioning and initial positioning of the tailstock tail cover ensure that the tail cover and the welded cables at the rear end will not be twisted arbitrarily during installation or disassembly, so as to avoid loosening of the cable and reduce the possibility of scrapping. The front end of the collet 2 is thick and the rear end is thin, and the side wall of the front part of the collet 2 is uniformly surrounded by a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com