High-efficiency combined type connected chisel and preparation method

A combined and high-efficiency technology, applied in the direction of hand chisels, hand-held tools, manufacturing tools, etc., can solve the problems of affecting the operation stability, sliding up and down, and the handle is slowly loosened, so as to improve the operation safety performance and prevent slippage , good grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

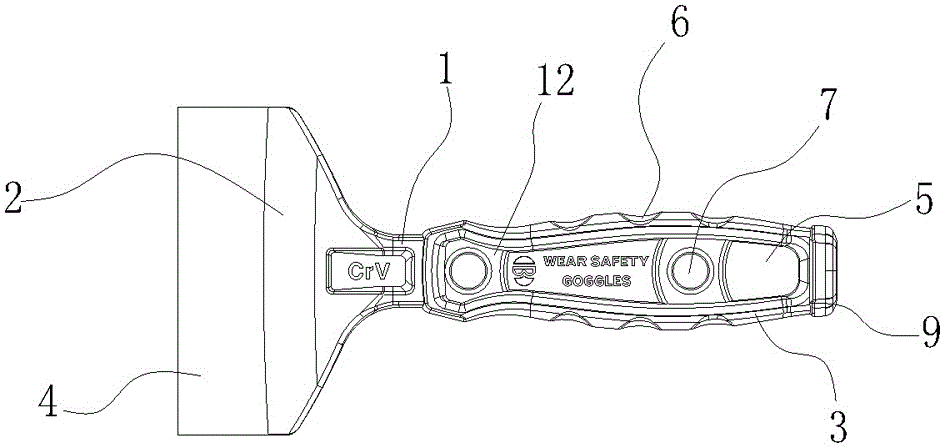

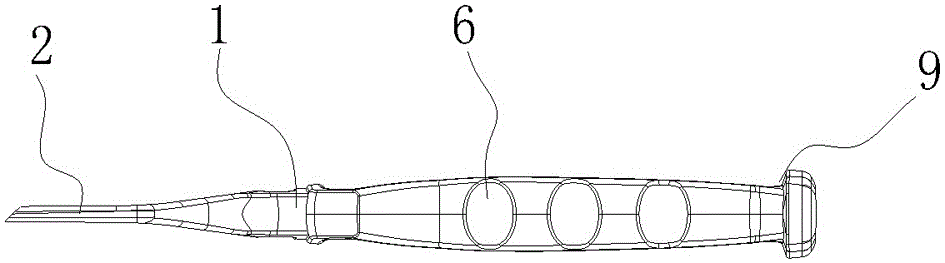

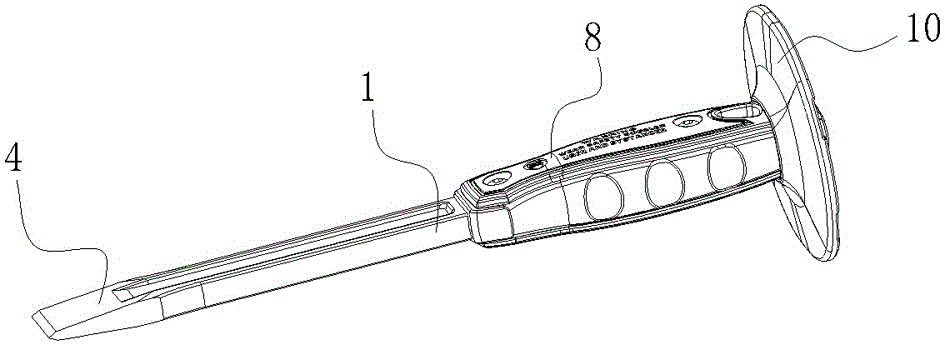

[0060] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a high-efficiency combined chisel includes a main part 1, the head of the main part 1 is the chisel head end 2, the tail of the main part 1 is the handle end 3, and the The chisel head end 2, the main body part 1 and the handle end 3 are integrally distributed;

[0061] The outer end of the chisel head end 2 is a chisel head 4 .

[0062] The chisel head end 2 is divided into a wide chisel and a pointed chisel, and the angle of the chisel head 4 is 30-90 degrees;

[0063] The tail of the handle end 3 is provided with a shock-absorbing hole 5 , and the two sides of the handle end 3 are respectively provided with a plurality of finger grooves 6 .

[0064] The handle end 3 is provided with a pair of plastic handle mounting holes 7 distributed at intervals, and the top and bottom of the handle end 3 are respectively provided with plastic handle mounting pieces 8, and the two plastic ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com