Wire marking machine

A scribing machine and wire technology, applied in workshop equipment, manufacturing tools, etc., to reduce manual damage, ensure scribing quality and scribing accuracy, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

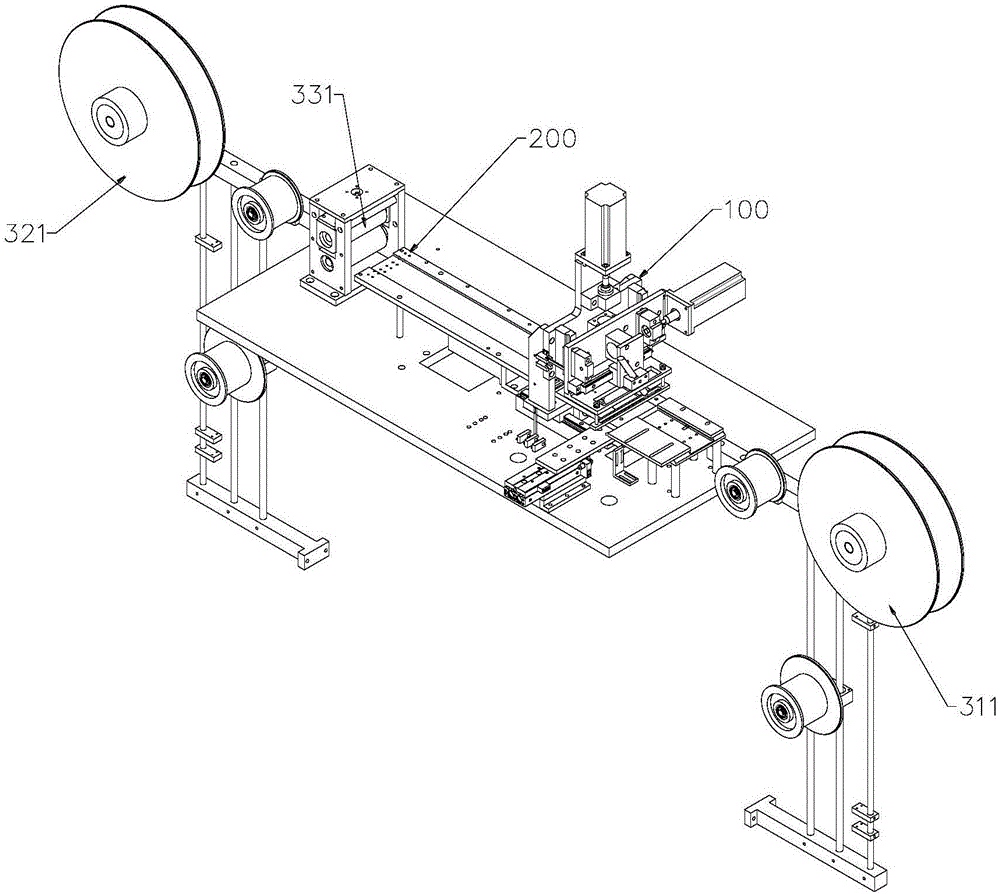

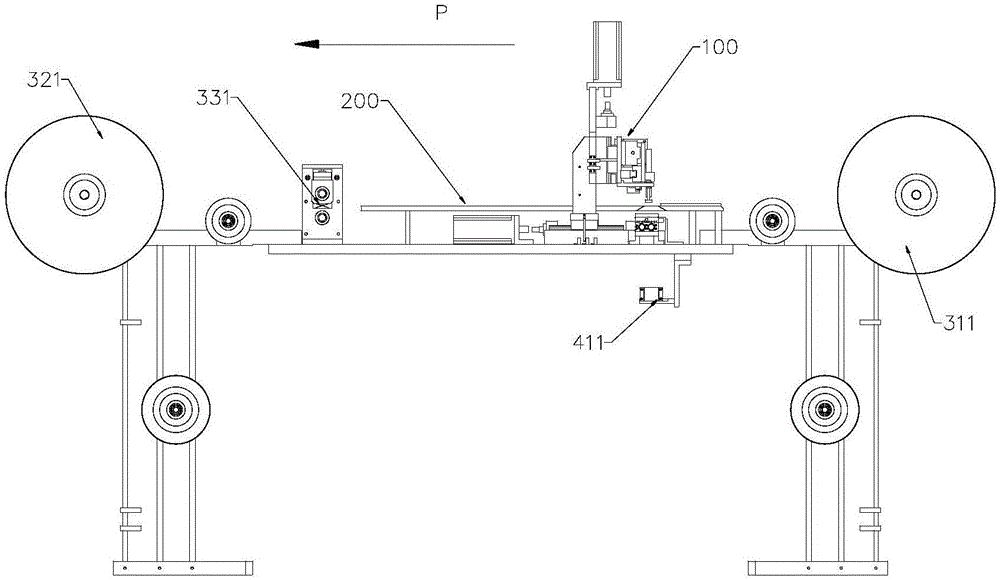

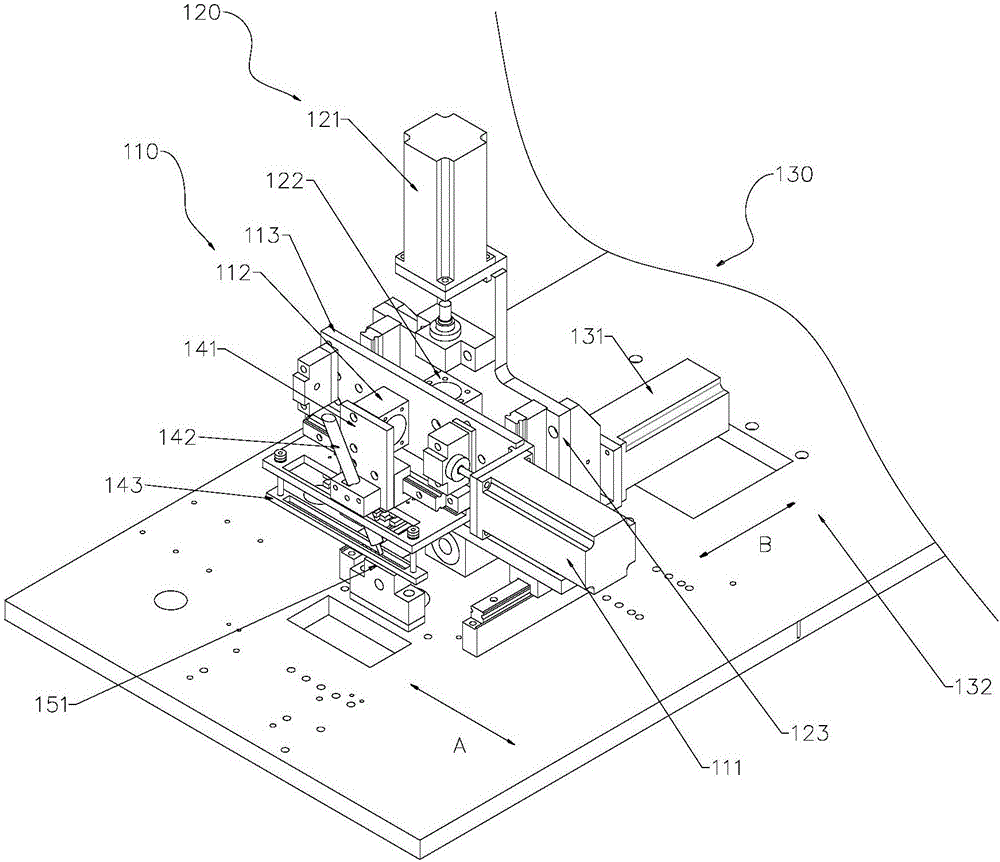

[0022] like Figure 1-3 As shown, the wire marking machine includes a conveying mechanism for conveying the wire and a marking mechanism 100 and a drying device 200 arranged in sequence along the conveying direction P of the wire; the marking mechanism 100 includes a wire for placing Placement area 151, mounting base 141, marking pen 142 positioned above placement area 151 and fixed on mounting base 141, first drive device 110 for driving mounting base 141 to move back and forth along first direction A, and for driving The second driving device 120 for the mounting seat 141 to move up and down in the vertical direction; the first direction A is perpendicular to the vertical direction.

[0023] When in use, the wire is transported by the conveying mechanism, and when the part of the wire to be marked is transported to the placement area 151, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com