A kind of value-added equipment for mixing plastics

A technology for equipment and plastics, which is applied in the field of quality and value-added of mixed plastics, can solve the problems of increasing capital investment in sorting equipment and increasing energy consumption, and achieve the effects of reducing energy consumption, simplifying production process and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

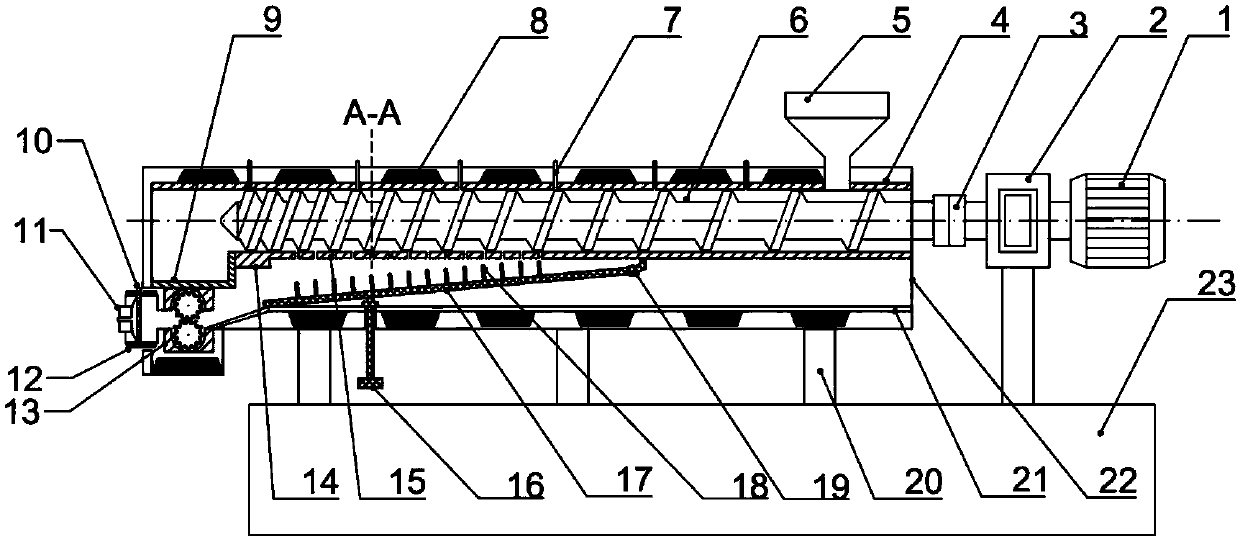

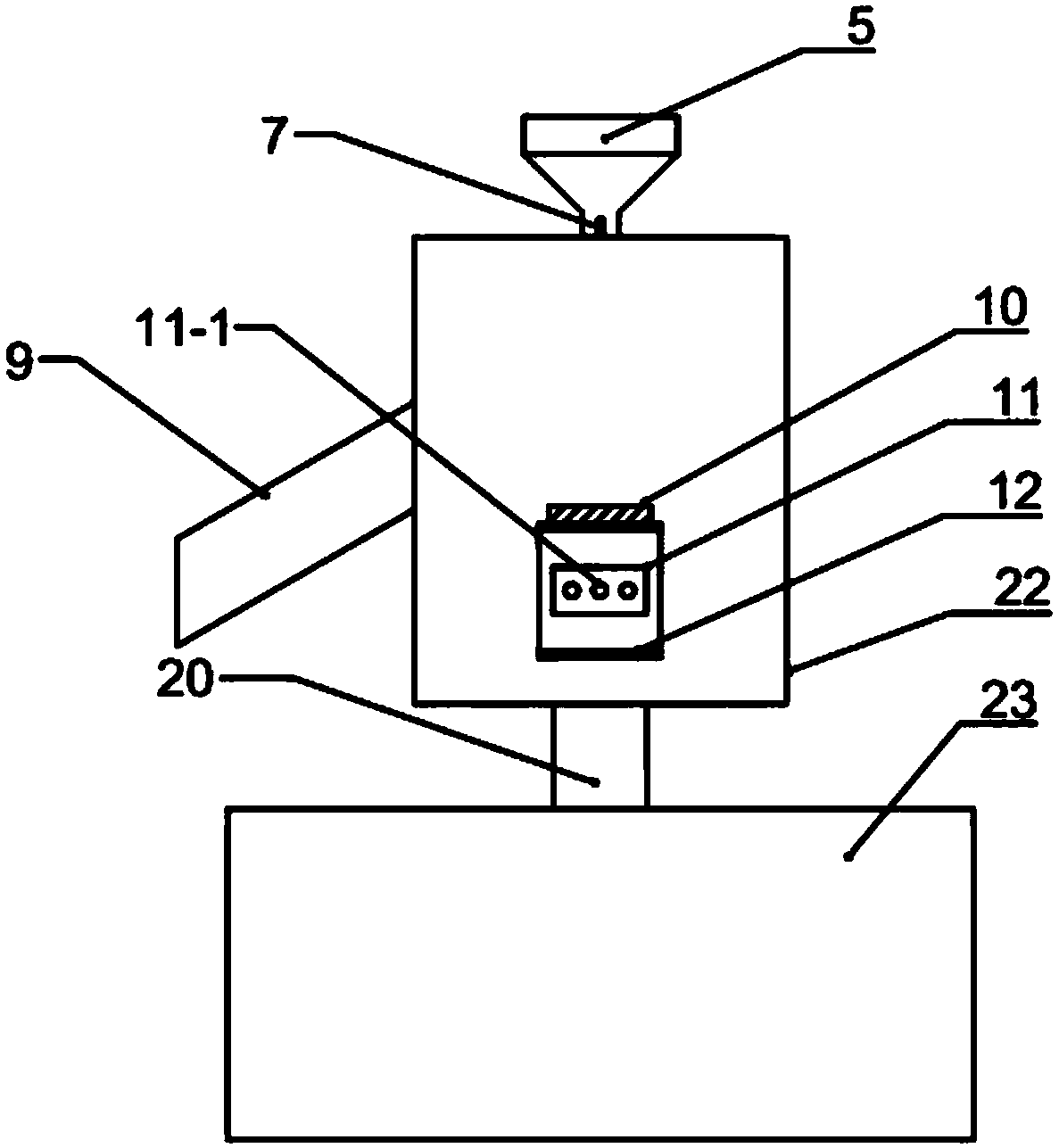

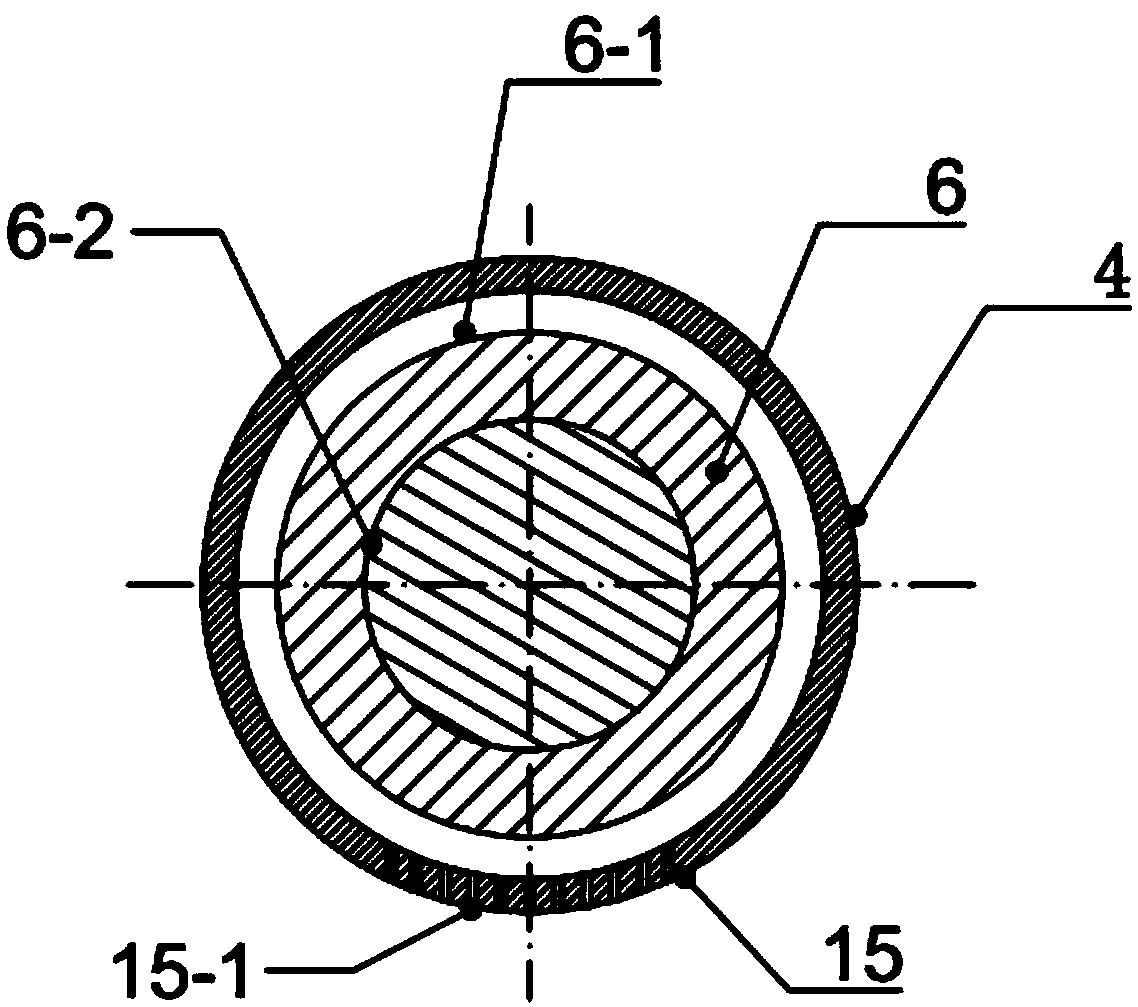

[0019] Such as figure 1 , figure 2 with image 3 As shown, a hybrid plastic quality-added value-added equipment includes a drive motor 1, a reducer 2, a base 23, a coupling 3, a screw 6, a barrel 4, a heating system 8, an exhaust system 7, a filter plate 15, Hand push rod 16, mesh cleaning plate 17, melt discharge pump 13, filter screen 10, extrusion die head 11, solid phase discharge port 9 and other main components; the reducer 2 is fixed on the machine through a bracket 20 On the seat 23, one end of the reducer 2 is connected with the driving motor 1, and the other end is connected with the shaft coupling 3, and the three constitute the transmission system of the equipment; the barrel 4 is fixed on the machine base 23 through three brackets 20, and the machine The barrel 4 is provided with an exhaust system 7 and a feeding port 5; the screw 6 is a gradually decreasing pitch screw, placed inside the barrel 4, one end is connected to the output end of the transmission syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com