Monitoring device with camera lens protection film capable of being automatically pasted and replaced and film pasting method of monitoring device

A technology of monitoring equipment and protective film, which is applied in the direction of packaging, etc., can solve the problems of blurred pictures and the inability of monitoring equipment to automatically replace the lens protective film, etc., to achieve the effects of avoiding blur, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

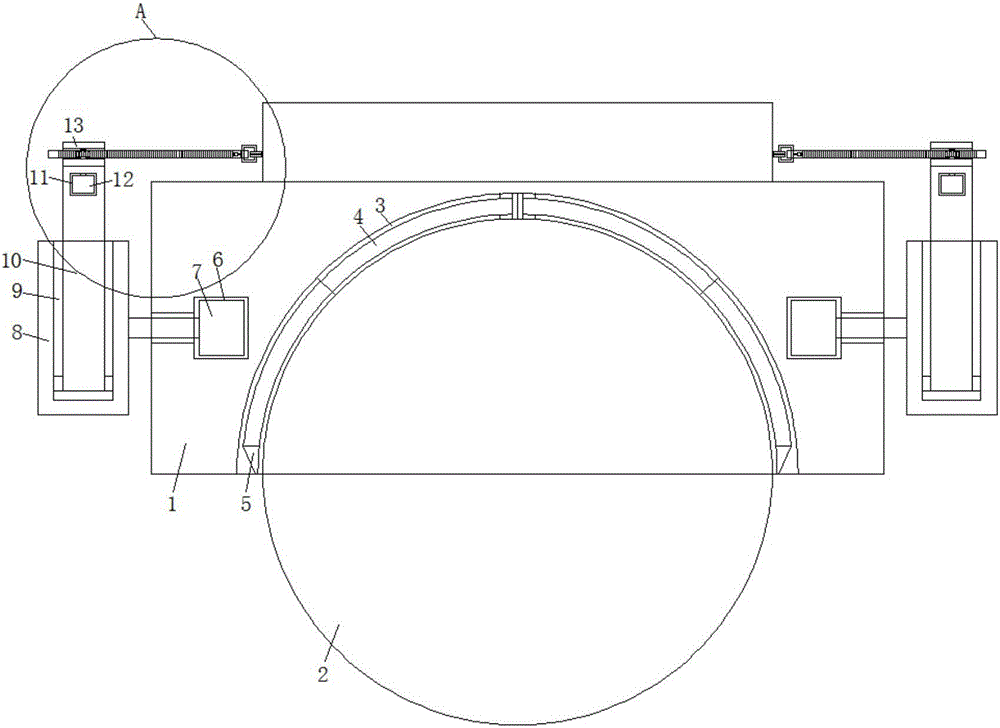

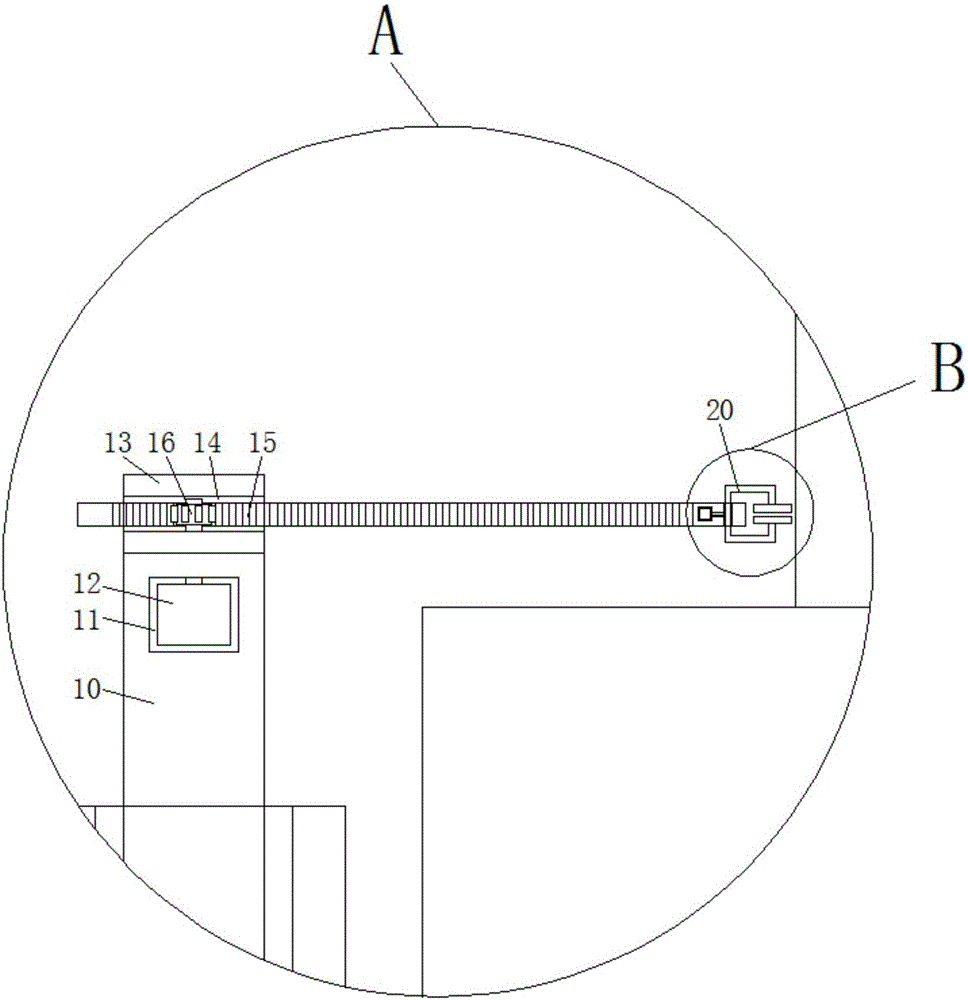

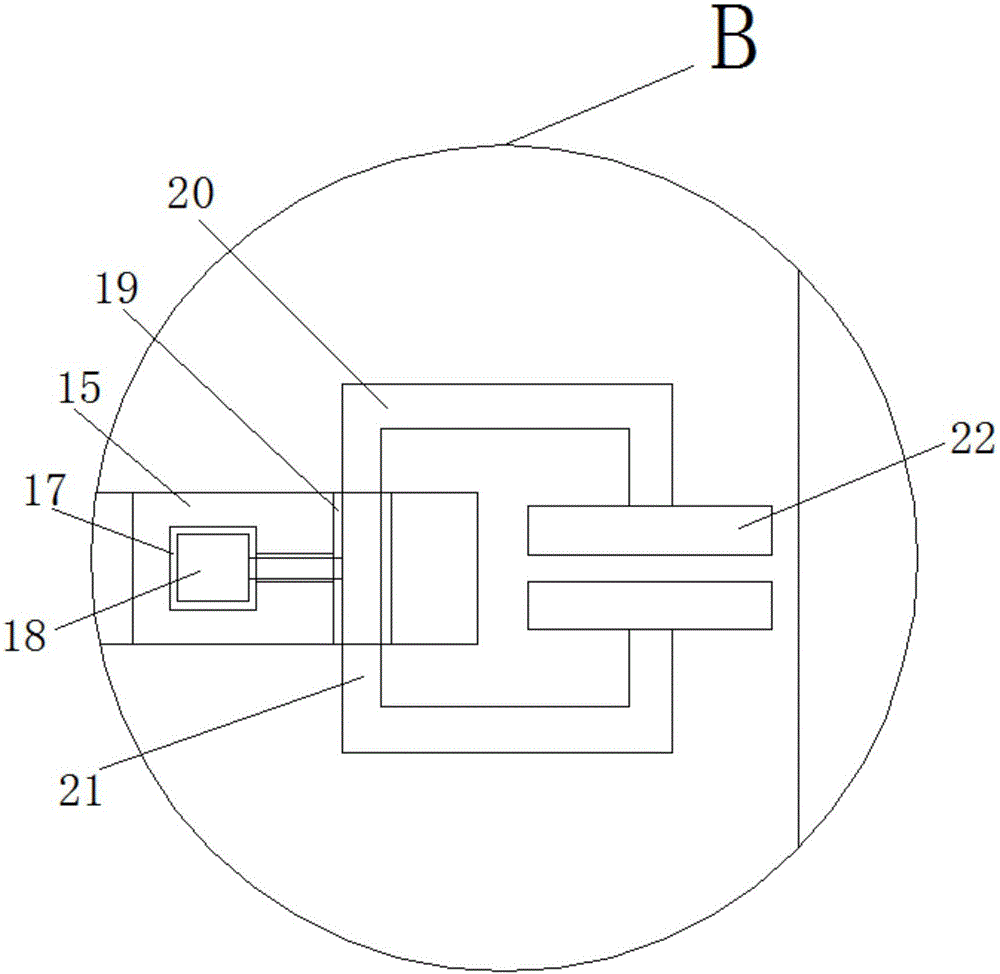

[0022] refer to Figure 1-3 , the present embodiment proposes a monitoring device that can automatically replace the lens protective film, including a device body 1 and a monitoring lens 2 disposed at the bottom of the device body 1, and first sliding grooves 3 are provided on both sides of the monitoring lens 2, And the first sliding groove 3 is located on the device body 1, the two first sliding grooves 3 are symmetrically arranged, and the first sliding rod 4 is slidably installed in the first sliding groove 3, and the first sliding rod 4 is close to the opening of the first sliding groove 3 A membrane changing head 5 is provided at one end of the device body 1, and a first placement chamber 6 is provided on both sides of the device body 1, and a first drive motor 7 is provided in the first placement chamber 6, and the output shaft of the first drive motor 7 is connected with a fixed Column 8, two fixed columns 8 are located on both sides of the device body 1, and the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com