Large prefabricated plate posture alignment hanging bracket and method

A prefabricated panel and attitude adjustment technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems that large prefabricated panels are difficult to achieve high precision, stability, and continuous attitude adjustment, and achieve the effect of high-precision construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

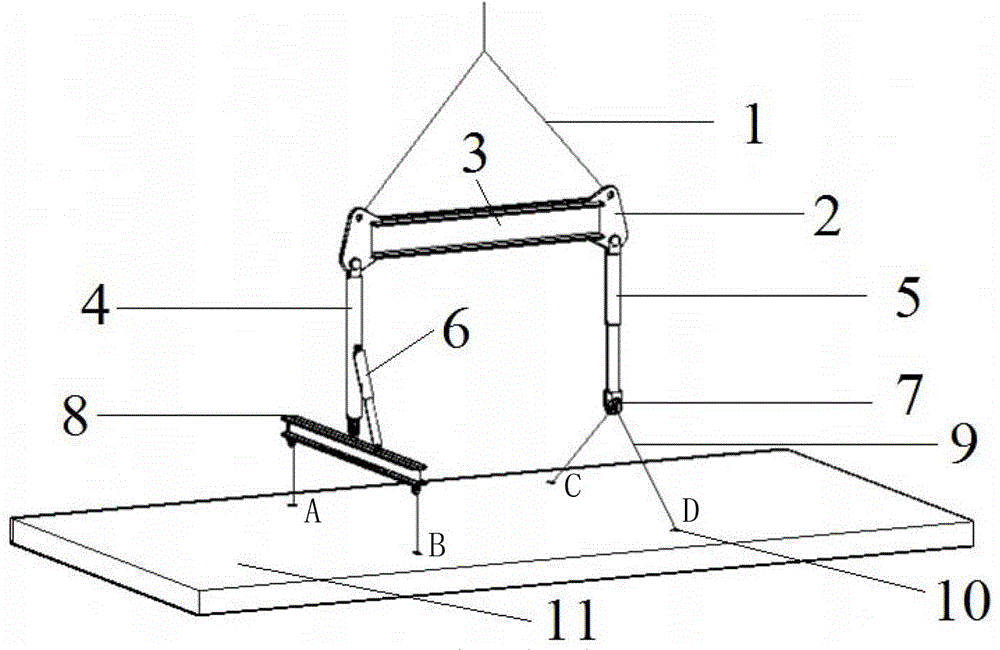

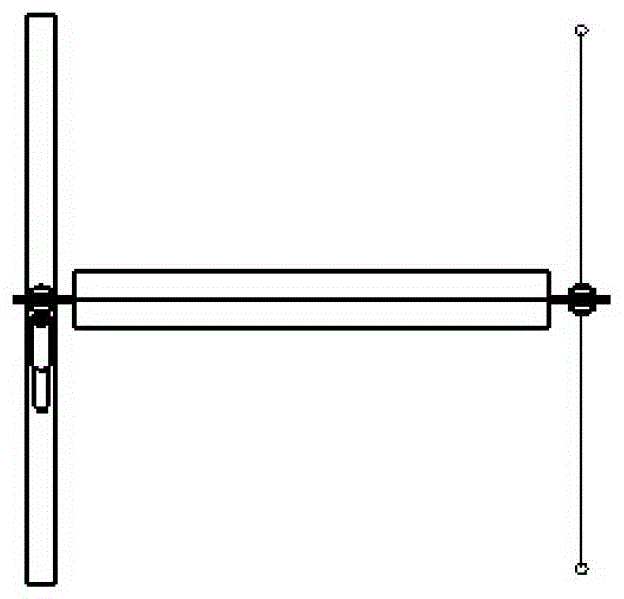

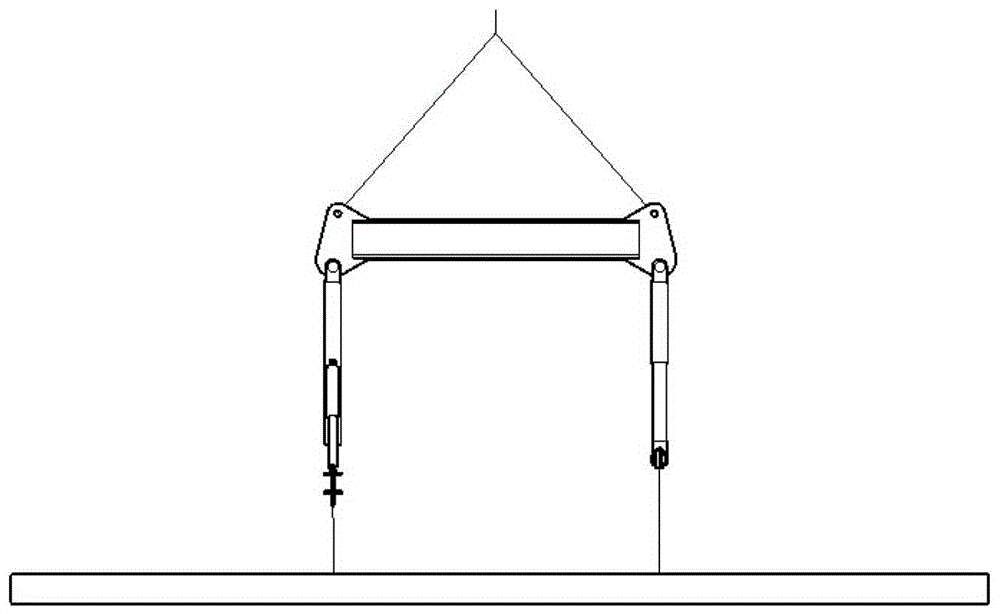

[0029] Such as Figure 1~10 As shown, a large-scale prefabricated panel posture adjustment hanger includes a suspension beam 3 and a horizontal adjustment system and a longitudinal adjustment system respectively connected to the two ends of the suspension beam 3; the two ends of the suspension beam 3 are provided with lifting lugs 2; The adjustment system includes a connecting rod 4, a lateral adjustment beam 8 and a lateral adjustment hydraulic cylinder 6. Hinged, the central axes of the connecting rod 4, the hanging beam 3 and the lateral adjustment beam 8 are perpendicular to each other, and the two ends of the lateral adjustment hydraulic cylinder 6 are respectively connected with the connecting rod 4 and the lateral adjustment beam 8, so Both ends of the horizontal adjustment beam 8 are respectively connected with a prefabricated board hanging steel wire rope 9; The ear 2 is hinged, and the lower end of the longitudinal adjustment hydraulic cylinder 5 is connected to the...

Embodiment 2

[0040] Use the large-scale prefabricated slab attitude-adjusting hanger in Example 1 to carry out the method for adjusting the attitude of large-scale prefabricated slabs. The lifting lugs 2 at both ends of the suspension beam 3 are connected to the hook of the crane through the upper steel wire rope 1, and the horizontal adjustment beam 8 is suspended by the steel wire ropes at both ends. Hang two points (A, B) on one end of the prefabricated slab 11, and hang two points (C, D) on the other end of the prefabricated slab 11 from both ends of the wire rope connected to the pulley 7; adjust the hydraulic cylinder 6 horizontally through wireless control to realize prefabrication Horizontal overturning of the panel 11; the longitudinal overturning of the prefabricated panel 11 is realized by wirelessly controlling the longitudinal adjustment of the hydraulic cylinder 5. In order to achieve a good adjustment effect, the connection of the two hanging points (A, B) of the horizontal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com