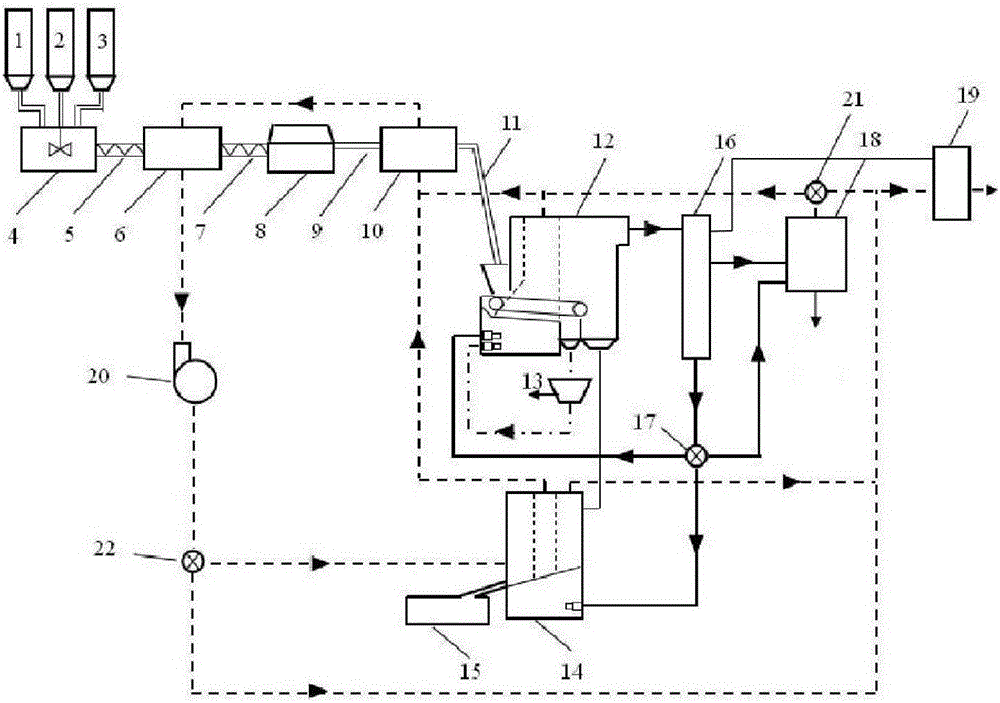

Sludge pyrolysis and carbon value reutilization co-treatment apparatus and method

A technology for processing equipment and sludge, which is applied in the field of sludge pyrolysis and carbon value resource co-processing equipment, can solve the problems of secondary environmental pollution, generation of waste water, waste gas, and complex sludge composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

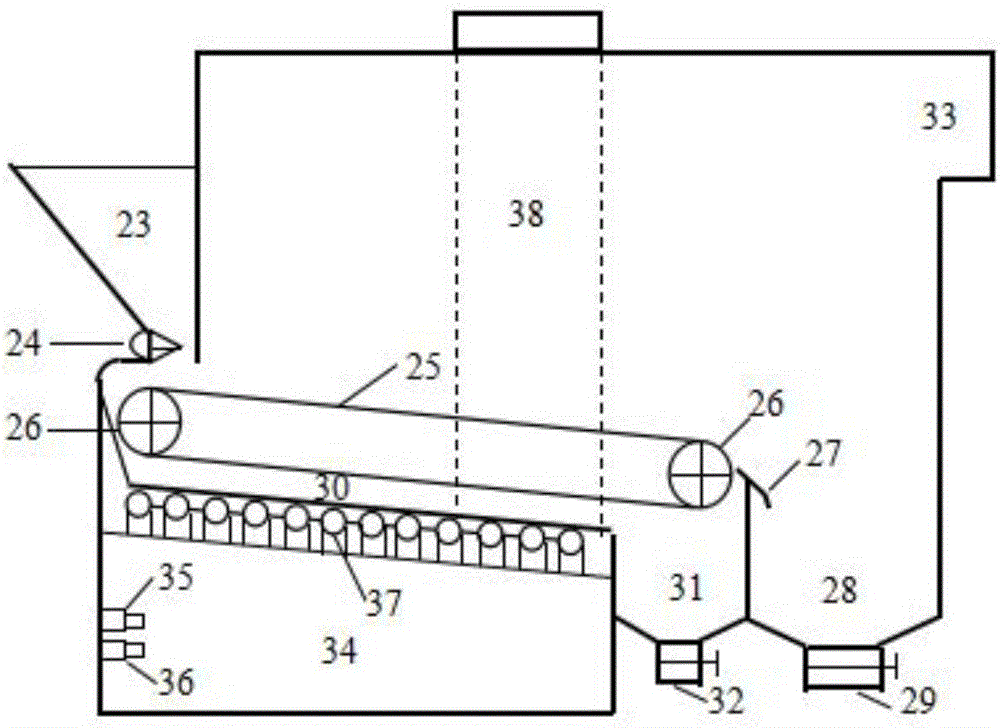

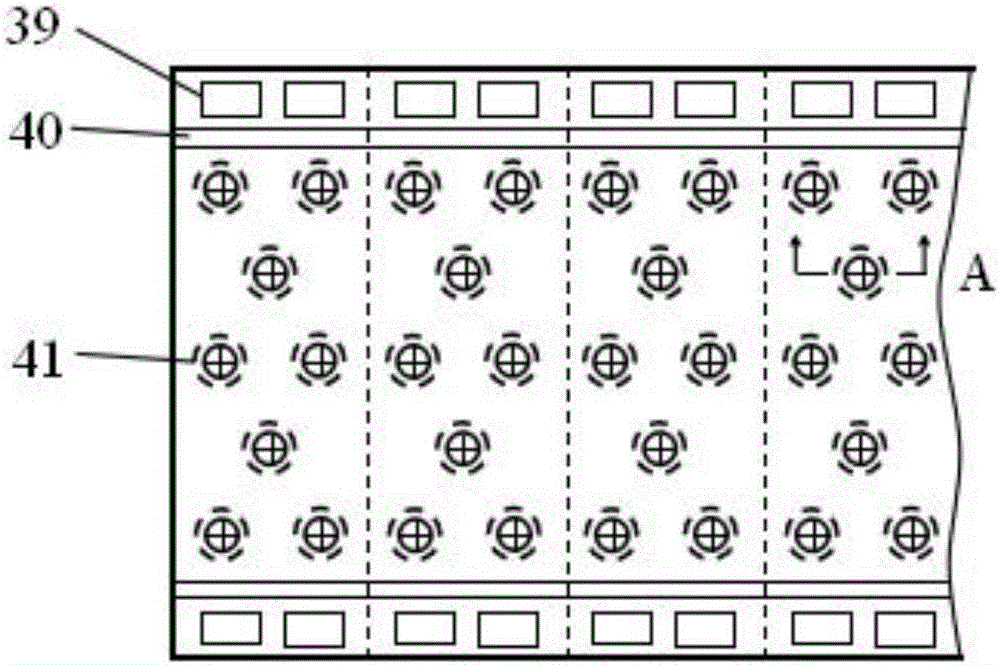

Embodiment 1

[0060] Add straw and ZnCl to the sludge 2 , the mass of straw is 15% of the mass of dry sludge, ZnCl 2 The mass is 10% of the dry sludge mass, and the three enter the mixing chamber for stirring and homogenization. It is sent to the first-stage air dryer by the screw conveyor to reduce the moisture content of the material to 50%; it is sent to the granulator by the screw conveyor, and coal tar is added as a binder. The mass ratio of the material to coal tar is 1:0.3 , prepared into a cylinder with a diameter of 8mm and a length of 15mm; it is sent to the second-stage air dryer by a belt conveyor to reduce the moisture content of the material to 20%, and at the same time raise the temperature of the molding material to 320°C to decompose the produced CO 2 Together with the evaporated moisture, it is carried away by the hot flue gas. The dried molding material is sent into the pyrolysis furnace through the feed pipe, the pyrolysis temperature is 650°C, and the residence time i...

Embodiment 2

[0063] Add straw and ZnCl to the sludge 2 , the mass of straw is 10% of the mass of dry sludge, ZnCl 2 The quality is 8% of the dry sludge quality, and the three enter the mixing chamber for stirring and homogenization. It is sent to the first-stage air dryer by the screw conveyor to reduce the moisture content of the material to 20%; it is sent to the granulator by the screw conveyor, and coal tar is added as a binder, and the mass ratio of the material to coal tar is 1:0.1 , prepared into a cylinder with a diameter of 8mm and a length of 15mm; it is sent to the second-stage air dryer by a belt conveyor to reduce the moisture content of the material to 5%, and at the same time raise the temperature of the molding material to 320°C to decompose the produced CO 2 Together with the evaporated moisture, it is carried away by the hot flue gas. The dried molding material is sent into the pyrolysis furnace through the feed pipe, the pyrolysis temperature is 750°C, and the residenc...

Embodiment 3

[0066] Add straw and ZnCl to the sludge 2 , the mass of straw is 20% of the dry sludge mass, ZnCl 2 The quality is 12% of the dry sludge quality, and the three enter the mixing chamber for stirring and homogenization. It is sent to the first-stage air dryer by the screw conveyor to reduce the moisture content of the material to 40%; it is sent to the granulator by the screw conveyor, and coal tar is added as a binder. The mass ratio of the material to coal tar is 1:0.5 , prepared into a cylinder with a diameter of 8mm and a length of 15mm; it is sent to the second-stage air dryer by a belt conveyor to reduce the moisture content of the material to 15%, and at the same time raise the temperature of the molding material to 320°C to decompose the produced CO 2 Together with the evaporated moisture, it is carried away by the hot flue gas. The dried molding material is sent into the pyrolysis furnace through the feed pipe, the pyrolysis temperature is 850°C, and the residence tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com