Geological drill pipe and its manufacturing method

A manufacturing method and geological drilling technology, applied to drill pipes, manufacturing tools, drill pipes, etc., can solve problems such as poor torsion resistance and impact resistance, instantaneous force overload, and failure of drilling tools, so as to improve performance and use Improvement of life, torsional performance, and reduction of accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

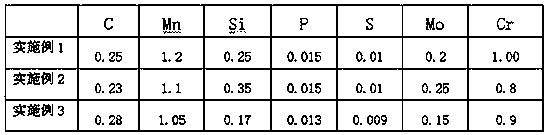

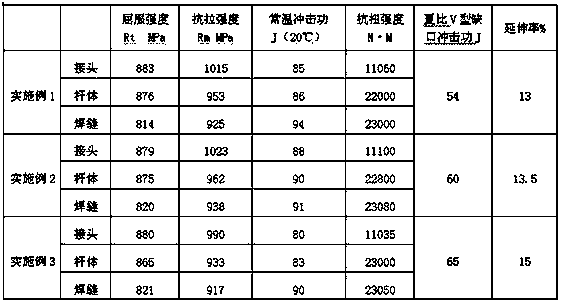

[0028] Table 1 is the chemical composition table of the embodiment of the present invention, in weight percentage, and the balance is Fe.

[0029]

[0030] The manufacturing method of the above-mentioned geological drill pipe comprises the following steps:

[0031] A. By weight percentage, add the chemical components (by weight percentage) in the above examples into the electric furnace, and smelt it into molten steel through the electric furnace. Speed continuous casting into φ73×9.19 drill pipe blank;

[0032] B. Using a 400 / 800T press, under the condition of a heating temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com