Maintenance scaffold for bridge girder erection machine

The technology of scaffolding and bridge erecting machine is applied in the field of overhauling scaffolding, which can solve problems such as inconvenience in overhauling, and achieve the effects of simple structure, convenient operation, and prevention of equipment loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

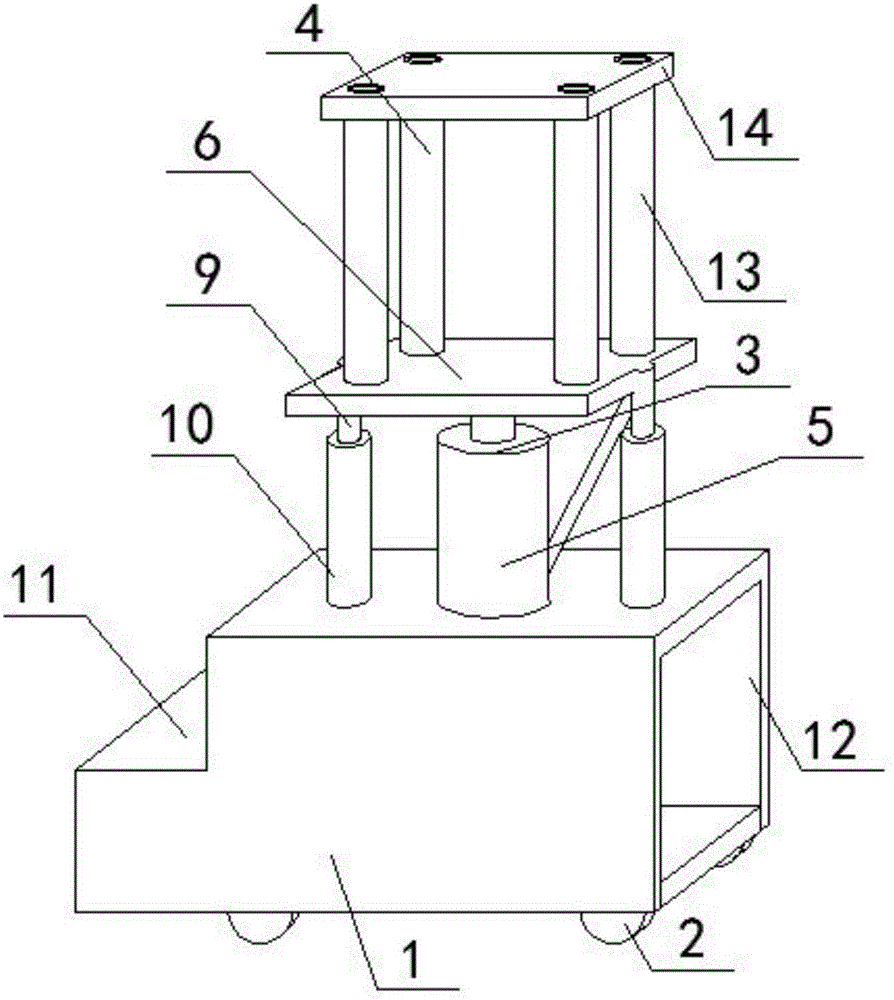

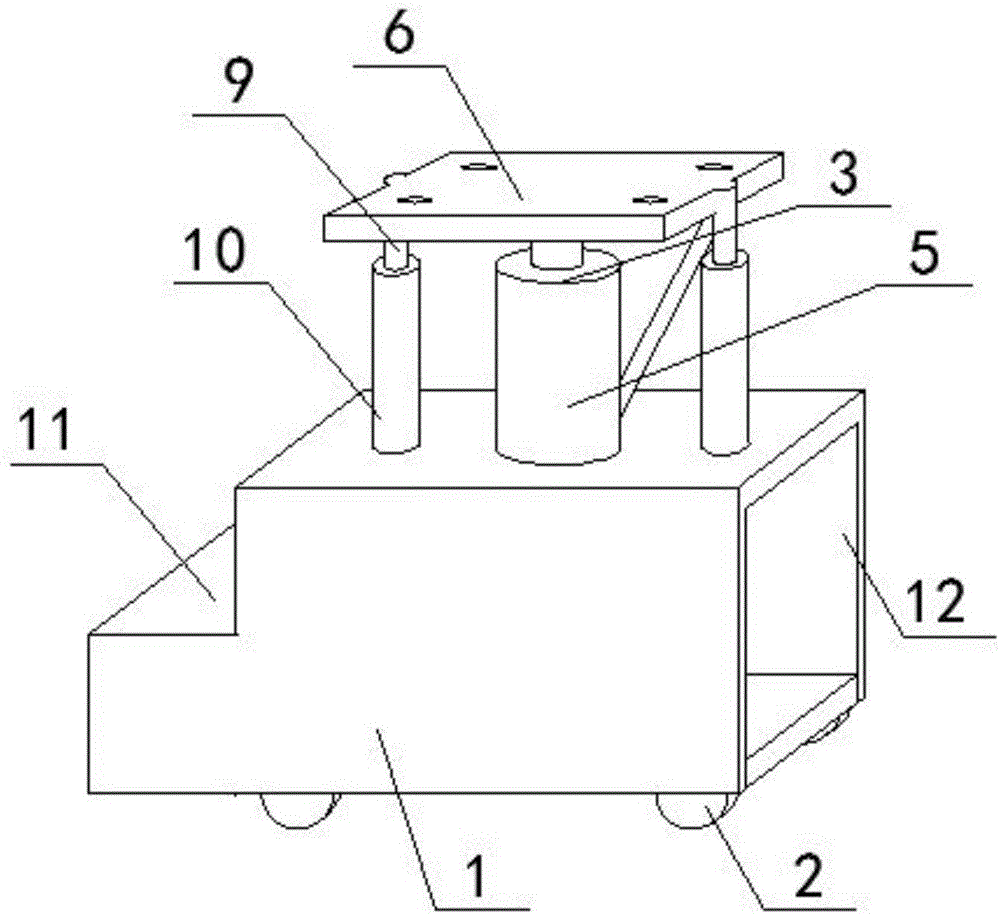

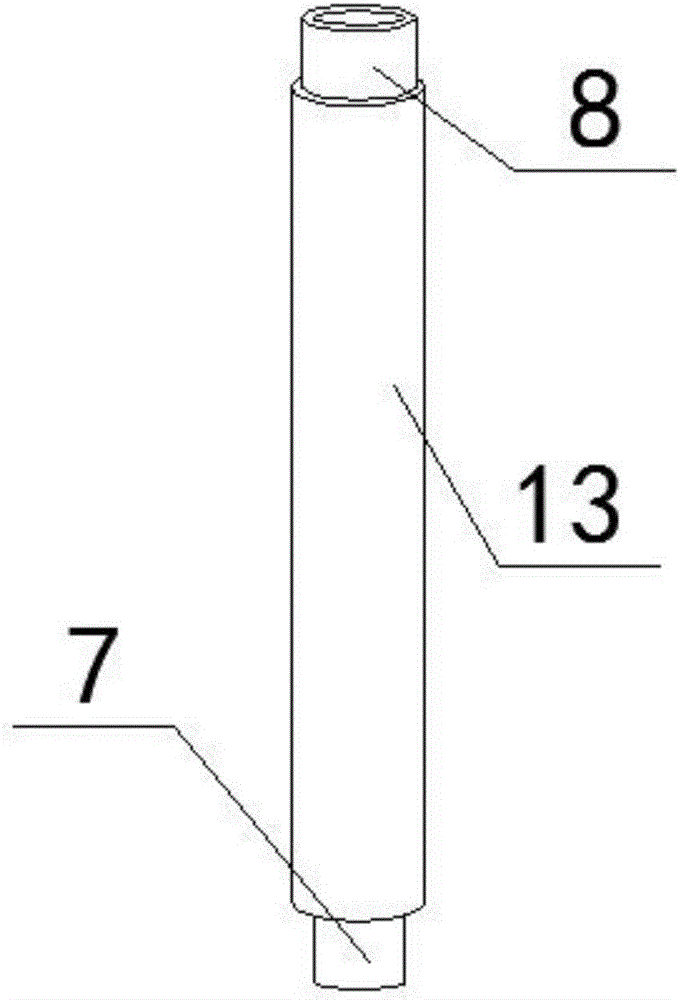

[0017] like Figure 1-4 as shown, figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of the storage tank and the lifting device of the present invention; image 3 It is a schematic diagram of the heightened pillar structure of the present invention; Figure 4 It is a structural schematic diagram of the heightening plate of the present invention.

[0018] refer to Figure 1-4 , the present invention proposes a maintenance scaffold for bridge erecting machines, including a storage box 1, rollers 2, a lifting device 3 and a heightening device 4; , the lifting baffle 6 is fixedly connected to the upper end of the jack 5, the roller 2 is located at the lower end of the reserve box 1, and the height-increasing device 4 is placed on the upper end of the lifting baffle 6; the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com