Steel strand stayed cable and manufacturing method thereof

A technology for steel strands and cable bodies, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of high cost, troublesome operation, troublesome processing, etc., and achieve the effects of preventing slippage, convenient processing and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

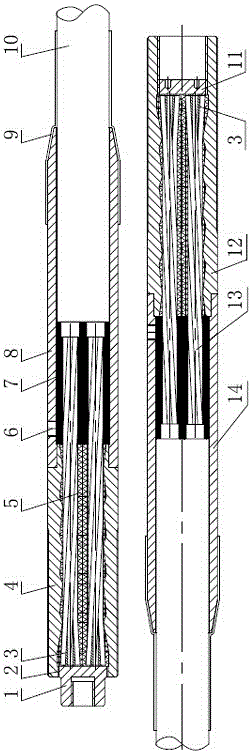

[0025] Embodiment: a kind of steel strand stay cable (referring to figure 1 ), including a cable body 10 composed of a plurality of steel strands 13 and an anchor end and a tension end connected to the end of the cable body.

[0026] Both ends of the cable body are sleeved with anchor sleeves and sealing cylinders, and the seal sleeves are fixed with the anchor sleeves. The anchoring end is the anchoring end anchoring sleeve 4 and the anchoring end sealing cylinder 8. The end of the anchoring end anchoring sleeve is screwed with the anchoring end cover 1, and the sealant 2 is applied between the anchoring end end cover and the inner wall of the anchoring end anchoring sleeve. It is the tension end anchor sleeve 12 and the tension end sealing cylinder 14, and the end of the tension end anchor sleeve is screwed with a tension end cover 11. Both ends of the cable body are stripped of the sheath, the steel strand sheath and the epoxy layer on the surface of each steel wire, expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com