Reinforced hydraulic buffer device

A hydraulic buffer and reinforcement technology, applied in the direction of shock absorbers, springs, springs/shock absorbers, etc., can solve the problems of device scrapping, waste of resources, and inability to ensure the sealing performance of the buffer device, so as to reduce the possibility of problems, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

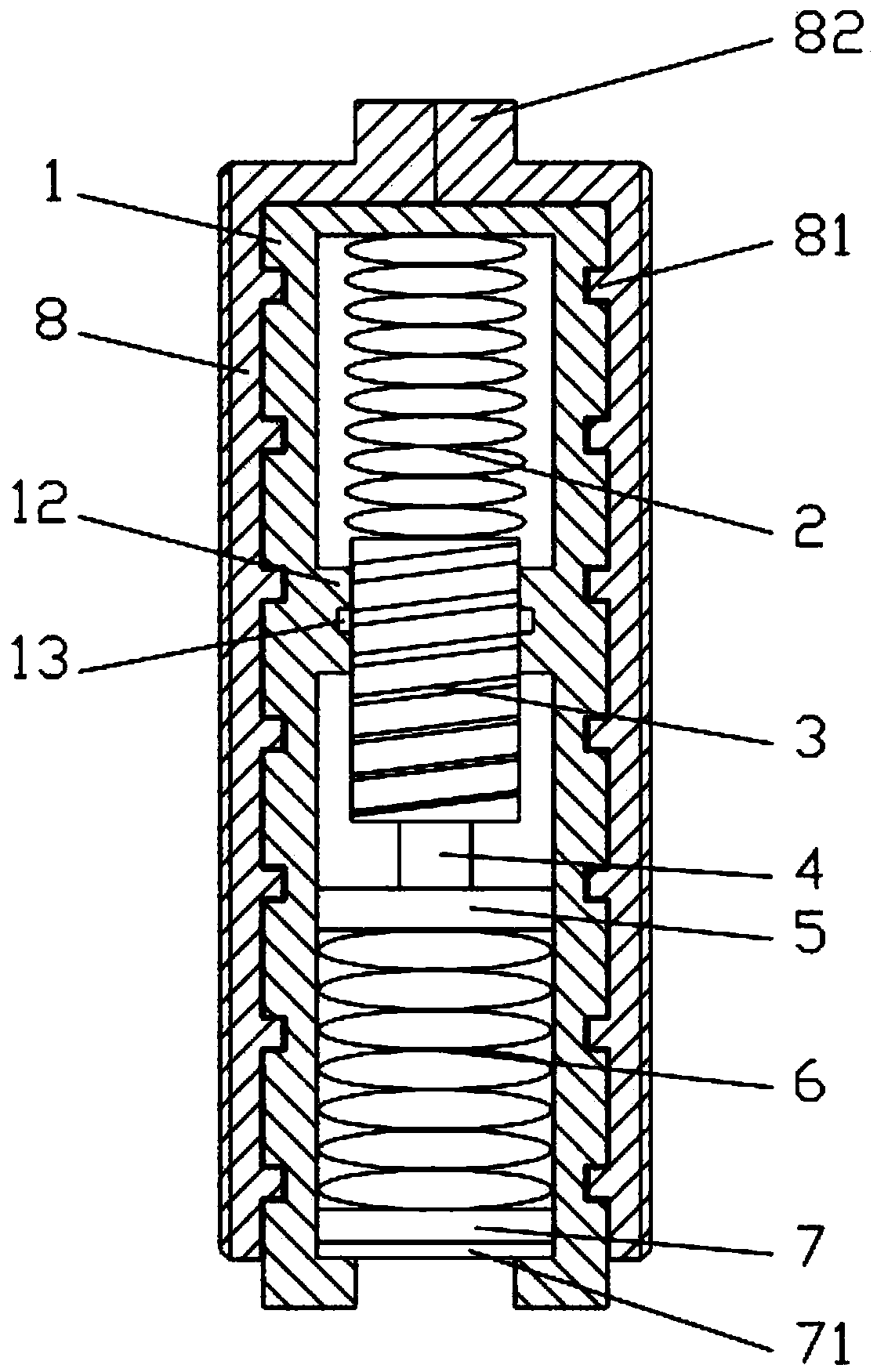

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

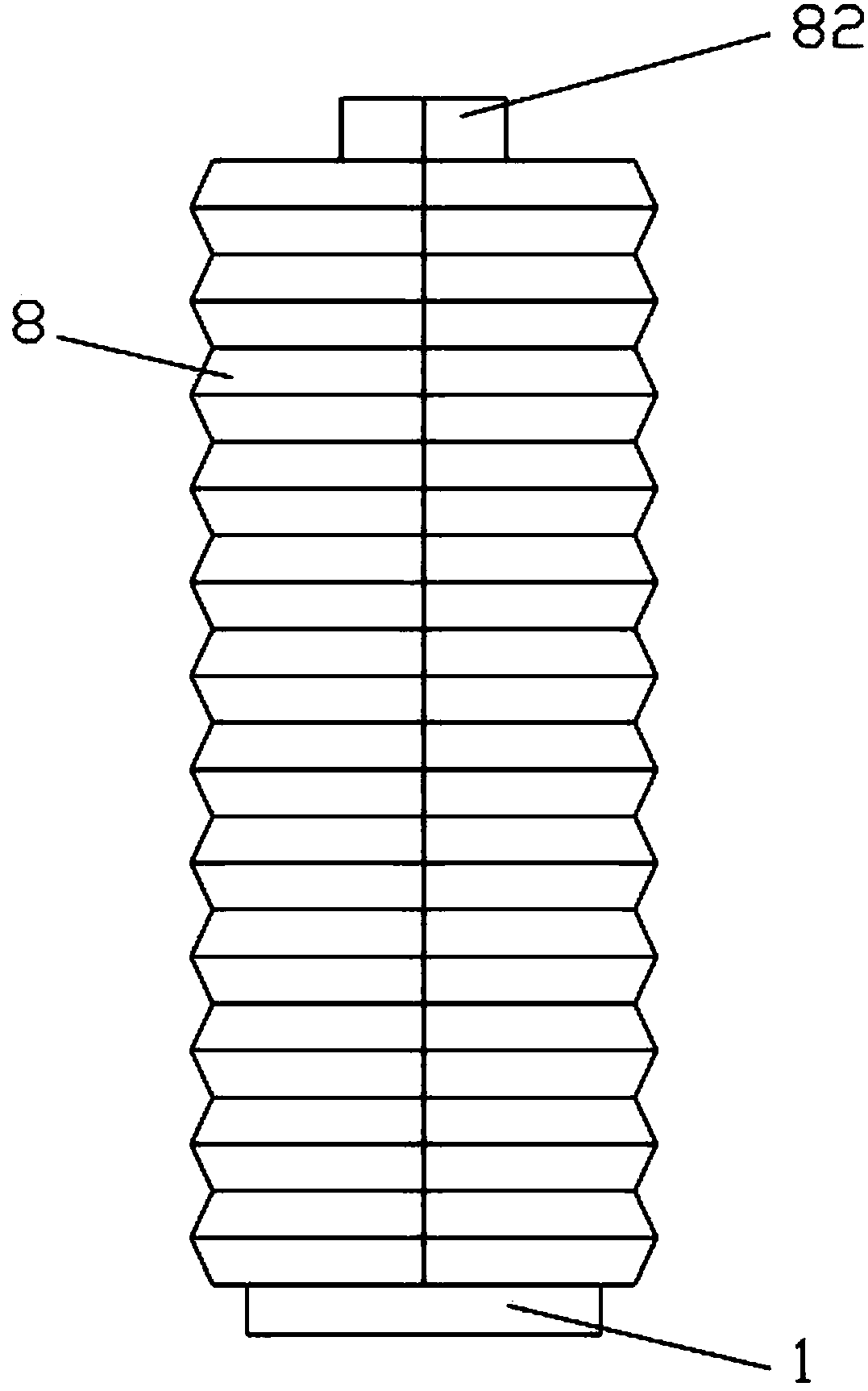

[0014] like figure 1 and figure 2 As shown, a reinforced hydraulic buffer device includes a core body 1, a casing 8 is sheathed outside the core body, a slot is provided on the outer surface of the core body 1, and a slot is provided on the inner surface of the casing 8 to match the shape of the slot. The protrusion 81 is stuck in the card slot, and the top of the housing 8 is fixed with a hexagonal nut 82, which is used to rotate the present invention into the corresponding place for fixing with a wrench. The housing 8 is divided into Two parts are convenient for installing the core body 1 in the housing 8. One end of the core body 1 is a closed end, and the other end is an open end, and the open end is connected to parts that need to be buffered on the machine.

[0015] A spiral groove piston 3 and an oil seal 5 are arranged inside the core body 1, and a first oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com