Device used for adjusting heat expansion difference of inner sleeve heat exchanger

A technology with thermal expansion difference and inner sleeve, which is used in heat exchanger sealing devices, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of large elastic compensation amount and large elastic compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

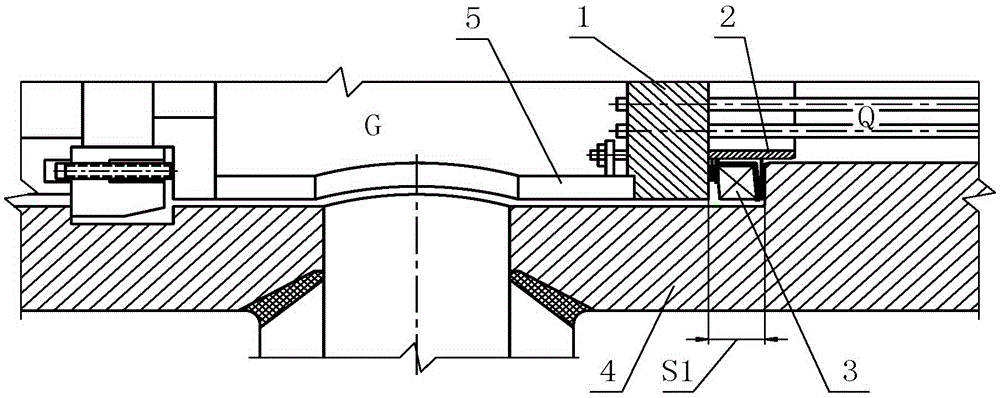

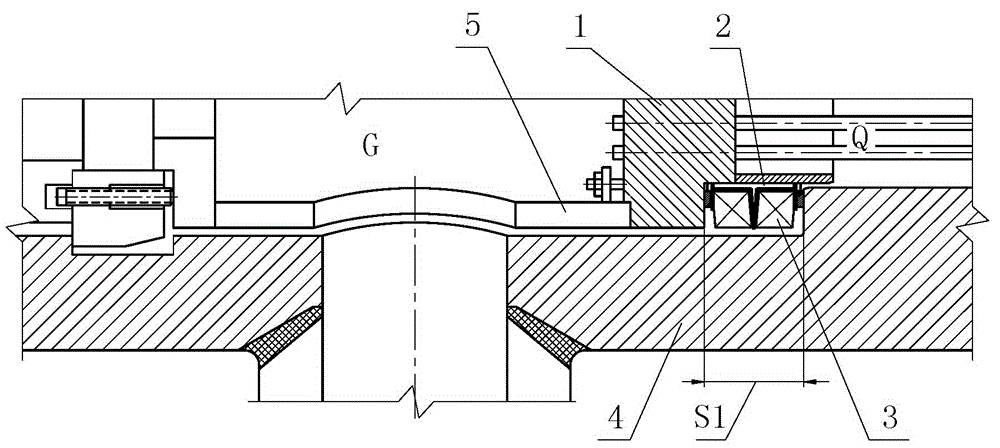

[0037] figure 2 is the second embodiment of the present invention, relative to figure 1 The improvement is that the tube plate 1 is a cake shape with a thin annular sealing surface and a thick middle with an annular step. The thick middle part protrudes toward the shell side Q, and the diameter of the protruding part matches the inner diameter of the shell side Q. The supporting sleeve 2 can be replaced in whole or in part to reduce the length of the supporting sleeve 2 . The compensation mechanism 3 in the figure is a structure in which double rings are stacked in opposite directions with cross-sectional oblique angles.

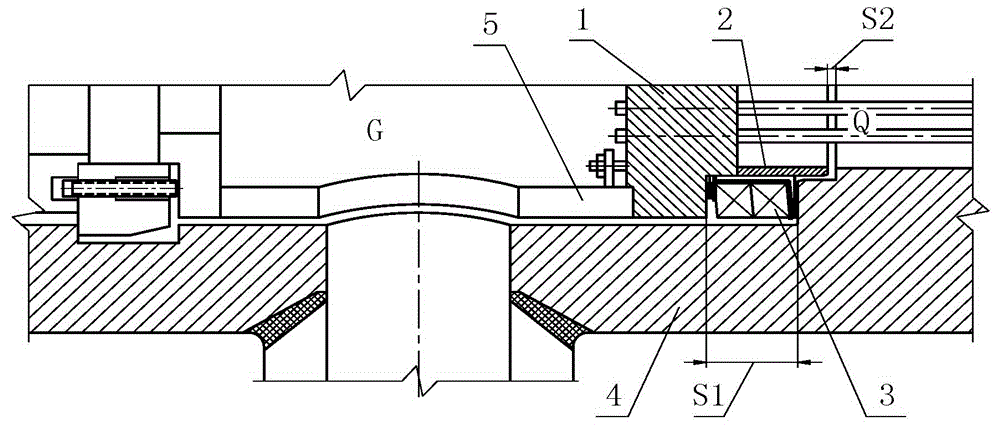

[0038] image 3 is the third embodiment of the present invention, relative to figure 2 The improvement is that the inner diameter of the support sleeve 2 is the same as the inner diameter of the shell side Q, so that in order to enable the support sleeve 2 to be inserted into the shell side Q, a pipe box inner wall with a small inner diameter at the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com