Aluminum alloy guide line monofilament axial stress fatigue test clamps and clamping method thereof

An aluminum alloy wire, fatigue test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Alloy wire single wire life, changing the surface state of wire materials, etc., to improve the accuracy and accuracy of the test, avoid repeated experiments, and reduce waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The axial stress fatigue test is carried out on the A6 aluminum alloy wire monofilament, and the diameter of the monofilament is 3mm.

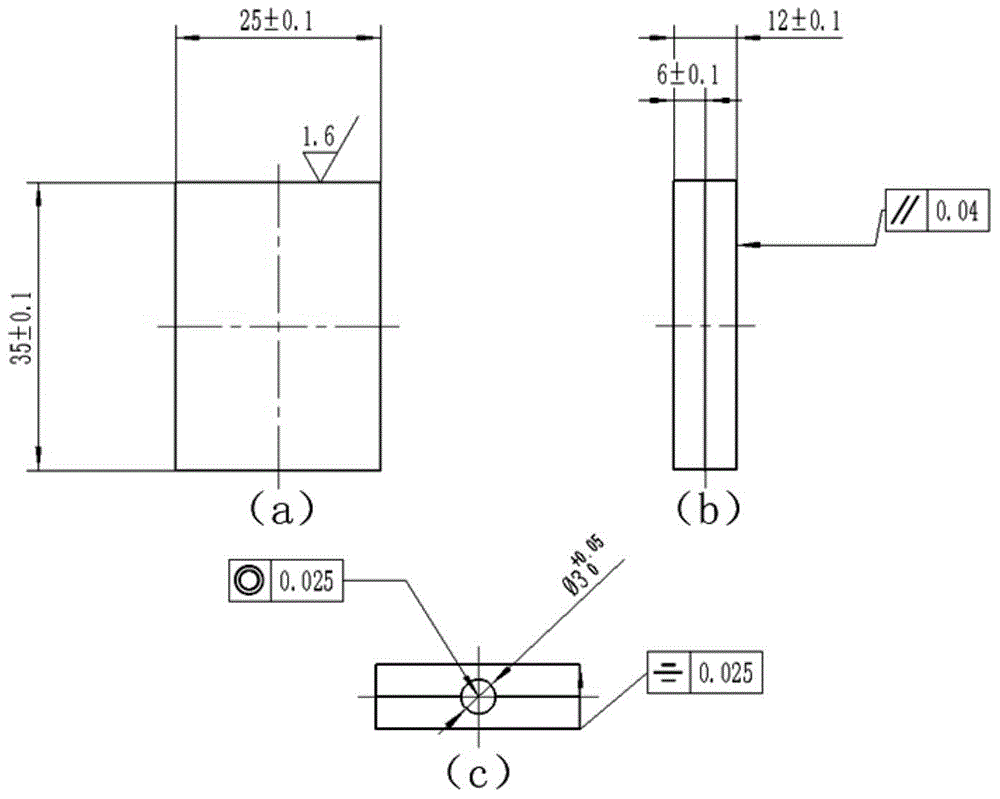

[0027] Select A6 aluminum alloy to prepare test fixtures, such as figure 1 As shown, there are two groups of test fixtures, and each group is composed of two monolithic fixtures. The length of the cuboid monolithic fixture is 35mm, the width is 25mm, and the height (thickness) is 6mm, which is twice the diameter of the monofilament; Set up a semi-cylindrical groove (set in the center of the surface where the length and width of the monolithic fixture are located, and the axial direction of the groove is consistent with the length direction of the monolithic fixture), when the two monolithic fixtures of each group are placed together (two and a half Cylindrical grooves are coaxially placed), and a cylindrical space is formed in the middle, and the diameter of the cylindrical space is 3mm. The connection between the semi-cylindrical groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com