Display substrate as well as driving method and preparation method thereof, display panel and display device

A technology of display substrate and driving method, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to adjust on-current and increased power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

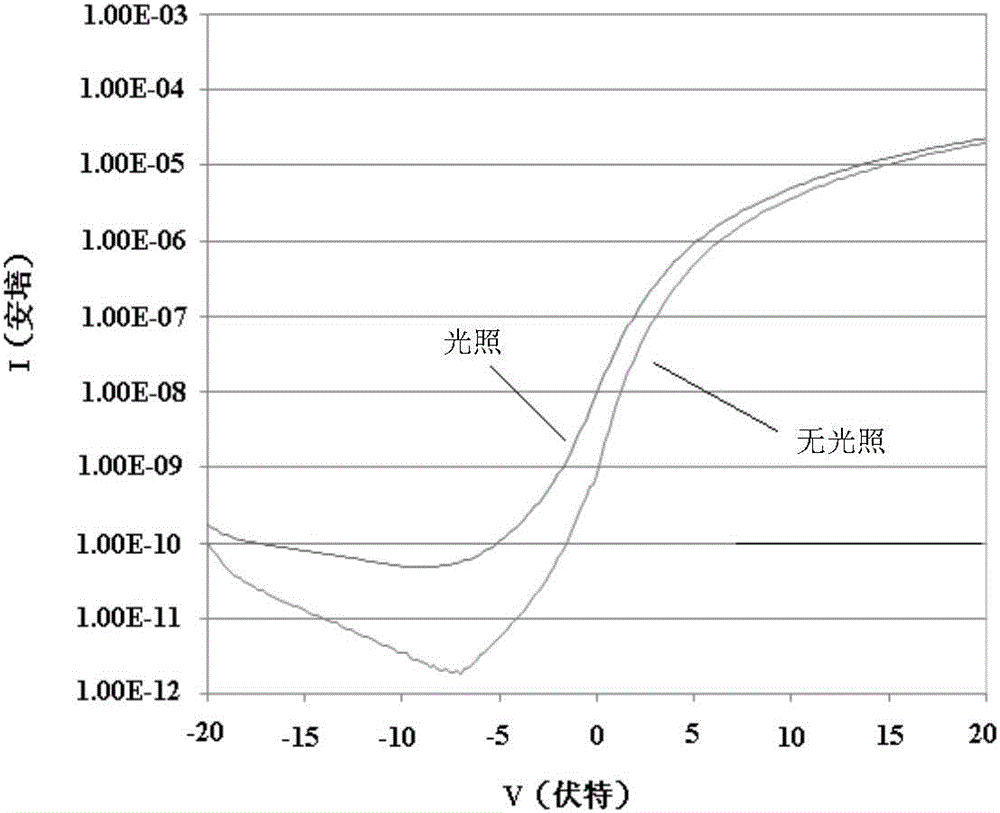

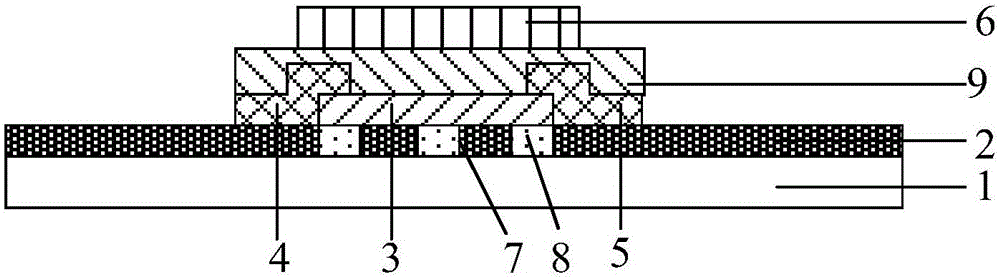

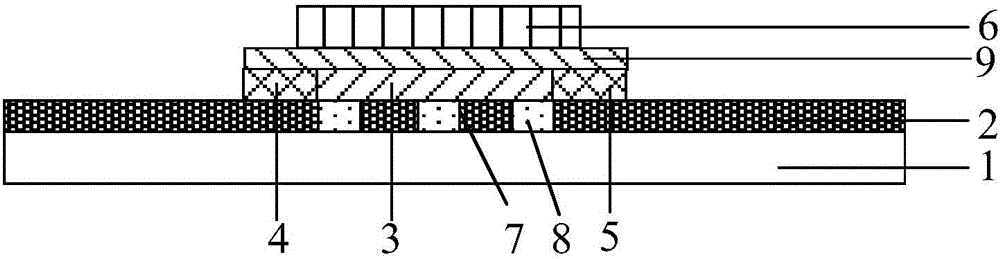

[0040] Please refer to Figure 2 to Figure 4 This embodiment provides a display substrate, including a base substrate 1, a black matrix layer 2, and a thin film transistor; the thin film transistor includes an active layer 3, a source electrode 4, a drain electrode 5, and a gate electrode 6; the black matrix layer 2 is located on the substrate On the base substrate 1, the active layer 3, the source 4 and the drain 5 are all located above the black matrix layer 2, the source 4 and the drain 5 are respectively connected to the active layer 3, and the gate 6 is located on the active layer 3. Above.

[0041] Such as figure 2 As shown, the display substrate further includes a gate insulating layer 9. Among them, the black matrix layer 2 is located on the base substrate 1, the active layer 3 is located on the black matrix layer 2, part of the source electrode 4 is located on the active layer 3, part of the drain electrode 5 is located on the active layer 3, and the gate insulating lay...

Embodiment 2

[0056] Please refer to Figure 5 This embodiment provides a method for driving a display substrate. The display substrate is the display substrate of Embodiment 1. The driving method includes:

[0057] Step S1, applying a first level to the gate to turn on the thin film transistor and make the electrochromic material in a light-transmitting state.

[0058] Step S2, applying a second level to the gate to turn off the thin film transistor and make the electrochromic material in a dark state.

[0059] It should be noted that after applying the first level or the second level to the gate, the gate will form a vertical downward electric field, that is, the direction of the electric field points to the electrochromic material, and the vertical downward electric field changes the electrochromic material The state (transparent state or dark state). Of course, the grid can also be combined with other electrodes to form an electric field, as long as the state of the electrochromic material ca...

Embodiment 3

[0066] Please refer to Figure 6 to Figure 11 , This embodiment provides a method for manufacturing a display substrate, including:

[0067] Step 101, forming a black matrix layer 2 on the base substrate 1, such as Figure 7 Shown.

[0068] Step 102, forming a hollow pattern 7 in the black matrix layer 2, such as Figure 8 Shown.

[0069] Step 103, arrange electrochromic material 8 in the hollow pattern 7, such as Picture 9 Shown.

[0070] Step 104, forming an active layer 3, a source electrode 4 and a drain electrode 5 on the black matrix layer 2. The source electrode 4 and the drain electrode 5 are respectively connected to the active layer 3, and the hollow pattern 7 corresponds to at least part of the active layer 3 Settings such as Picture 10 Shown.

[0071] Of course, after step 104, it also includes:

[0072] Step 105, forming a gate insulating layer 9 on the active layer 3, the source electrode 4 and the drain electrode 5, such as Picture 11 Shown.

[0073] Step 106, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com