Insulator string lifter

An insulator string and lifter technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of difficult handling of the external structure of the insulator string, safety accidents of staff, long working time, etc. Danger-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

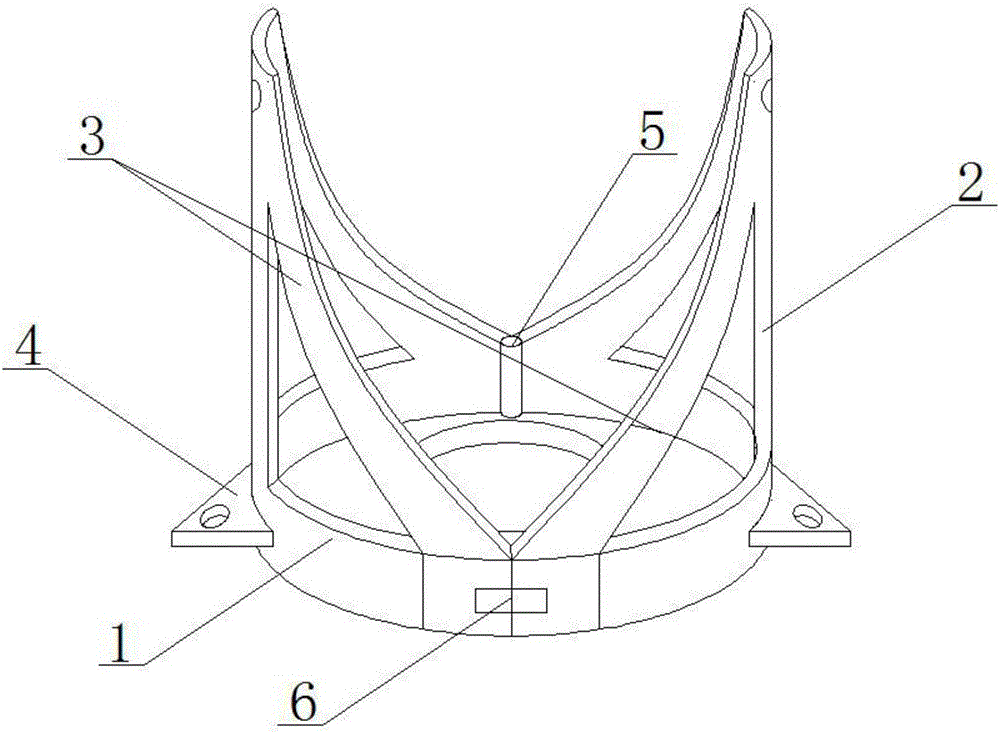

[0017] The main structure of the insulator string lifter of the present embodiment, such as figure 1 As shown, including the base 1, the upper surface of the base 1 is concaved into a groove matching the porcelain skirt of the insulator, the bottom of the groove is provided with a through hole matching the insulator, the upper left and right sides of the base 1 are fixed with hanging bars 2, and the hanging bars 2 The upper part is provided with a hanging hole, and the hanging bar 2 and the base 1 are also connected with at least one balance bar 3, the balancing bar 3 is fixed on the edge of the base 1, and the two sides of the base 1 opposite to the hanging bar 2 are respectively provided with hinges 5 and buckle6.

[0018] The specific implementation method is to open the buckle 6 of the base 1, open the base 1 through the hinge, and then nest the insulator porcelain skirt in the groove of the base 1, the lower part is stuck through the through hole in the base 1, and the ba...

Embodiment 2

[0020] In this embodiment, on the basis of the above-mentioned embodiments, it is further defined that the suspension bar 2 is connected to the base 1 through two balance bars 4 , and the planes where the hinges 5 and buckles 6 of the left and right suspension bars 2 are located are mirror images. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0022] In this embodiment, on the basis of the above embodiments, it is further defined that the outer side of the base 1 on which the hanging bars 2 are fixed is provided with a fixing block 4, and the fixing block 4 is provided with a fixing hole. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com