Prefabricated-type flexible DC cable terminal stress cone structure

A flexible DC and cable termination technology, applied in the direction of cable termination, cable accessories, cable installation, etc., can solve the problem of no proposed design theory and design method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Use rated voltage ±320kV prefabricated flexible straight cable terminal.

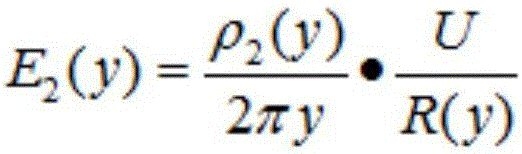

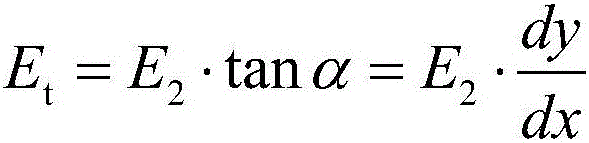

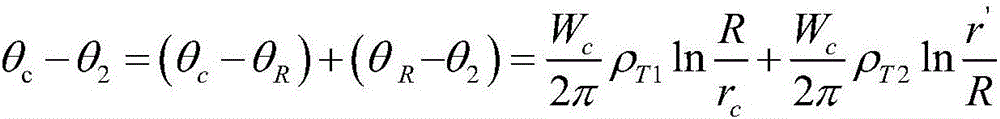

[0088] 1. The radial electric field intensity E at the stress cone curve y 2 (y) calculate

[0089] For ±320kV prefabricated flexible straight cable terminal, U=320kV; ρ 1,0 = ρ 2,0 =10 16 Ω.m; a 1 =0.06°C -1 , a 2 =0.05°C -1 ; θ c =90°C,w c =68W; ρ T1 =3.5K.m / W, ρ T2 =3.3K.m / W; r c = 26.5mm, R = 50.5mm; γ 1 = 2.2, γ 2 =1.69, bring the above data into the radial electric field intensity E at the stress cone curve y 2 (y) Calculation formula:

[0090] E = 7.29 × 10 14 × y 0.29 1.27 × 10 7 × ( E 2.28 × 10 ...

Embodiment 2

[0097] Adopt rated voltage ±200kV prefabricated flexible straight cable terminal.

[0098] 1. The radial electric field intensity E at the stress cone curve y 2 (y) calculate

[0099] For ±200kV prefabricated flexible straight cable terminals, U=200kV; ρ 1,0 = ρ 2,0 =10 16 Ω.m; a 1 =0.06°C -1 , a 2 =0.05°C -1 ; θ c =90°C,w c =66W; ρ T1 =3.5K.m / W, ρ T2 =3.3K.m / W; r c = 20.4mm, R = 36.4mm; γ 1 = 2.2, γ 2 =1.69, bring the above data into the radial electric field intensity E at the stress cone curve y 2 (y) Calculation formula:

[0100] E = 5.63 × 10 14 × y 0.27 8.47 × 10 6 × ( E 2.81 × 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com