Inclined plate feeding system with sludge discharging function

A sloping plate and functional technology, applied in the feeding/discharging device of the settling tank, controlling the inclination of the settling equipment, settling tank and other directions, can solve the problems of packing collapse, turbid water outlet, time-consuming, etc., to reduce work intensity, Prevent overall displacement and ensure the effect of water turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

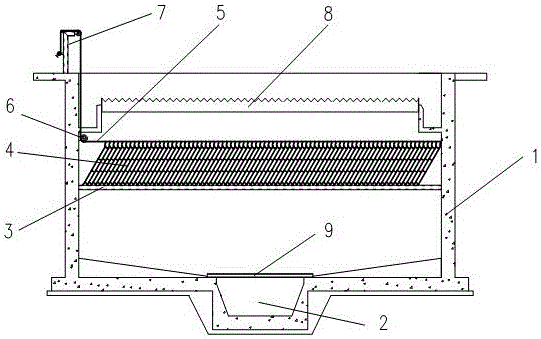

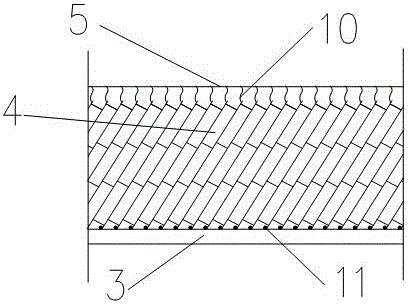

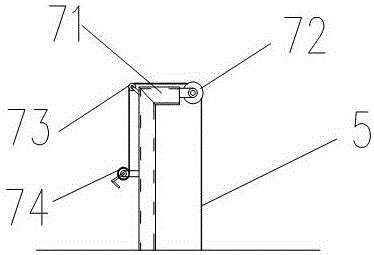

[0020] Such as Figure 1~3 The shown sloping plate packing system with mud discharge function includes a tank body 1, the bottom of the tank body 1 is provided with a liquid outlet 2, the middle part of the pool body 1 is fixed by a bracket 3 at the bottom of the sloping plate packing 4, and the top of the sloping plate packing 4 Pulled by the main steel wire rope 5, the main steel wire rope 5 forms a connection system with adjustable displacement distance through the No. 1 fixed pulley 6 on the pool wall and the transmission structure 7 on the top of the pool body 1; shaped deflector 8; the outlet 2 is provided with a sludge baffle 9; the main steel wire rope 5 is tied to the top of each sloping plate packing 4 by connecting the steel wire rope 10, and the bottom of each sloping plate packing 4 is supported by a support 3 The limit threaded steel 11 on the top is clamped; the transmission structure 7 includes a 7-shaped fixed frame 71, and one end of the horizontal side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com