Car washing pool and assembling method thereof

A car washing and pool body technology, which is applied in the direction of vehicle exterior cleaning devices, swimming pools, public buildings, etc., can solve the problems of insufficient cleaning at the bottom, waste of resources, unsatisfactory cleaning effect, etc., and achieve a simple, fast and convenient installation process. Strong sex and layering, ideal cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

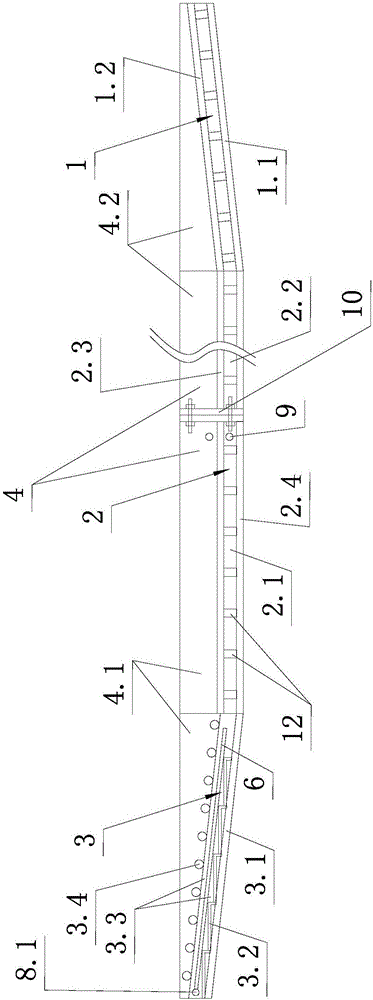

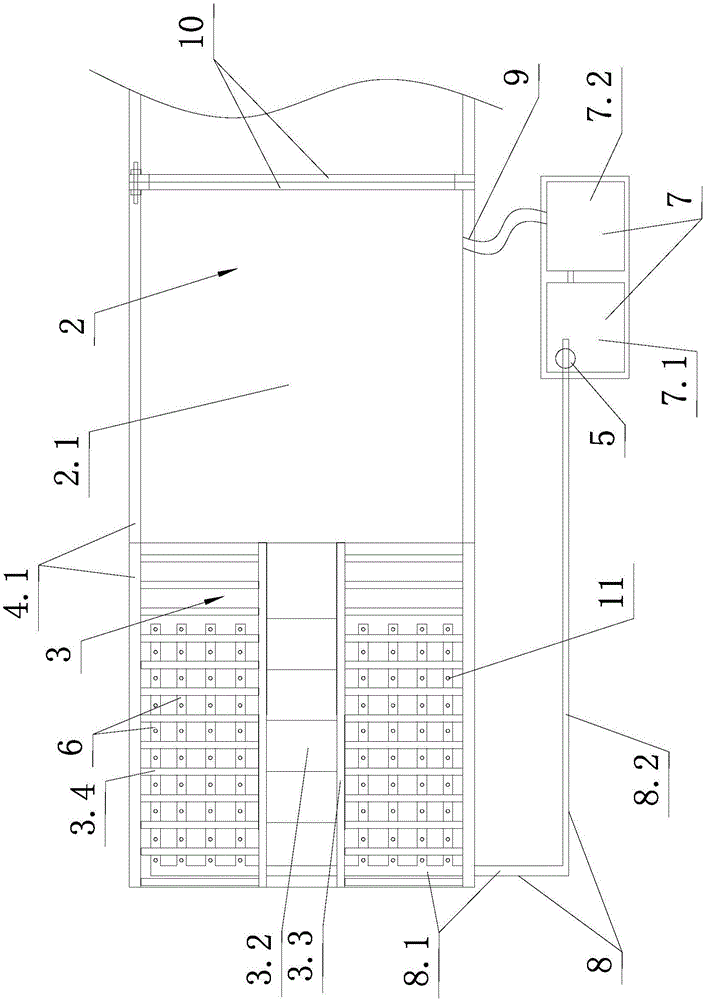

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] like figure 1 , figure 2 Shown, the car wash basin of the present invention, it comprises downhill part 1, water accumulation part 2, uphill part 3 and spraying system. The front end of the water accumulation part 2 is fixed to the rear end of the uphill part 3; the rear end of the water accumulation part 2 is fixed to the front end of the downhill part 1. The left side wall 4 is provided on the left side of the downhill part 1 , the pond part 2 and the uphill part 3 , and the right side wall 4 is provided on the right side. The side wall 4 is a ribbed side wall 4, and each side wall 4 is composed of a front wall 4.1 and a rear wall 4.2, and the water accumulation part 2 is composed of the water accumulation front part 2.1 and the water accumulation rear part 2.2; the water accumulation front part 2.1, the upper The slope part 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com