Multilayer-section fracturing technique pipe column and construction method thereof

A technology of process pipe string and construction method, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve the problems of difficult water preparation, large amount of flowback fluid, and difficult treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

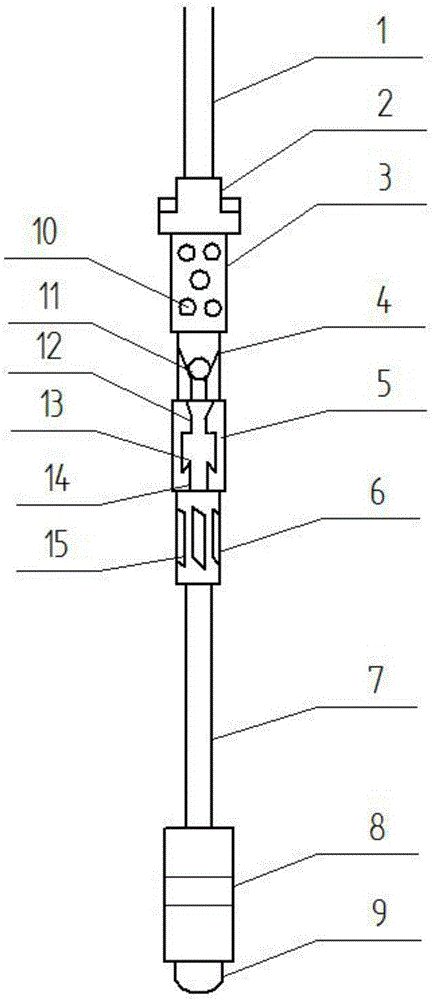

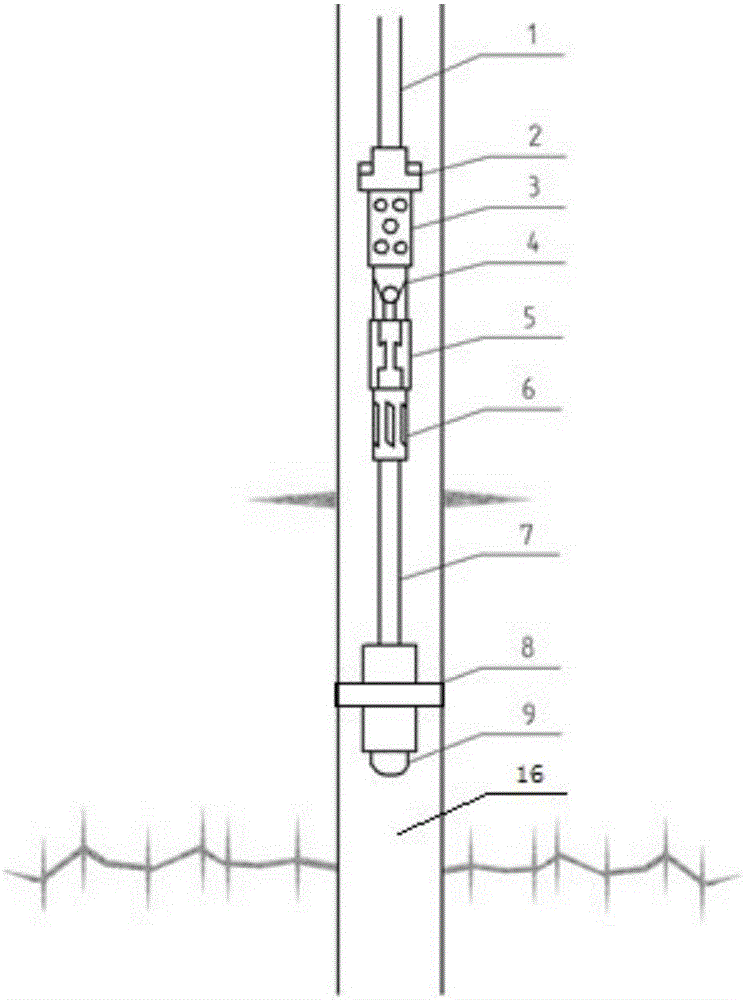

[0035] Such as figure 1 As shown, a multi-stage fracturing process string includes an upper oil pipe 1, a safety hand 2, an injector 3, a ball seat 4, an oscillator 5, a sand mixer 6, and a lower oil pipe connected sequentially from top to bottom. Tubing 7, packer 8 and plug 9.

[0036] In this embodiment, the upper oil pipe 1, the hand 2, the injector 3, the ball seat 4, the oscillator 5, the sand mixer 6, the lower oil pipe 7, the packer 8 and the plug 9 are sequentially arranged from top to bottom The connected pipe string is lowered into the predetermined reconstruction position in the well; the injector hole 10 is aimed at the target section; the sealing ball 11 corresponding to the ball seat 4 at the lower end of the injector 3 is put in from the wellhead, and when the sealing ball 11 is located on the injector 3 When the ball seat 4 at the lower end is on, the liquid flow channel below the ball seat is blocked; sandblasting and perforation are carried out through the h...

Embodiment 2

[0038] On the basis of Example 1, the injector 3 is provided with holes 10 ; the sand mixer 6 is provided with pressure-guiding sandblasting holes 15 . The multi-stage fracturing process string also includes a sealing ball 11, and the sealing ball 11 is put into the ball seat 4 and returned to the ball seat 4 to realize the opening and closing of the channel of the sand mixer 6.

[0039] The multi-stage fracturing process string described in the present invention is an integrated string for sandblasting and perforating fracturing. The liquid outlet channel is changed by casting sealing balls, and different liquid outlet channels are used in different construction stages: sandblasting and perforating In the first stage, a hydraulic sand blaster is used for sand blasting and perforation; in the fracturing stage, a bottom hole sand mixer is used to quickly and evenly mix the high-sand ratio sand-carrying fluid injected into the tubing with the liquid injected into the annulus form...

Embodiment 3

[0041] On the basis of Embodiment 1, the oscillator 5 is a Helmholtz oscillator, which consists of an upstream nozzle 12 , a vibrating chamber 13 and a downstream nozzle 14 sequentially connected from top to bottom. When the fluid flows through the vibrating chamber 13, hydraulic pulsation is generated under the modulation of the vibrating chamber 13, so the water flow ejected from the nozzle forms a fluctuating pressure with large and small pressures. Collision with the downstream collision wall can generate pressure disturbance to form pulse vibration, and the fluid forms a self-excited pulse jet with strong vibration. The invention uses the self-excited pulse vibration principle generated by the oscillator and the swirl mixing principle of the sand mixer to fully and uniformly mix the sand-carrying liquid and the pure liquid in the annular space in a short period of time, which can further improve the sand mixing effect and achieve complex fracture network pressure. The pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com