Compound type temperature-resisting viscoelastic self-diverting acid as well as preparation method and application thereof

A self-steering acid and viscoelastic technology, which is applied in chemical instruments and methods, earthwork drilling, and drilling compositions, can solve the problems of being unsuitable for medium and high temperature wells, and achieve low cost, convenient liquid preparation, and raw materials. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

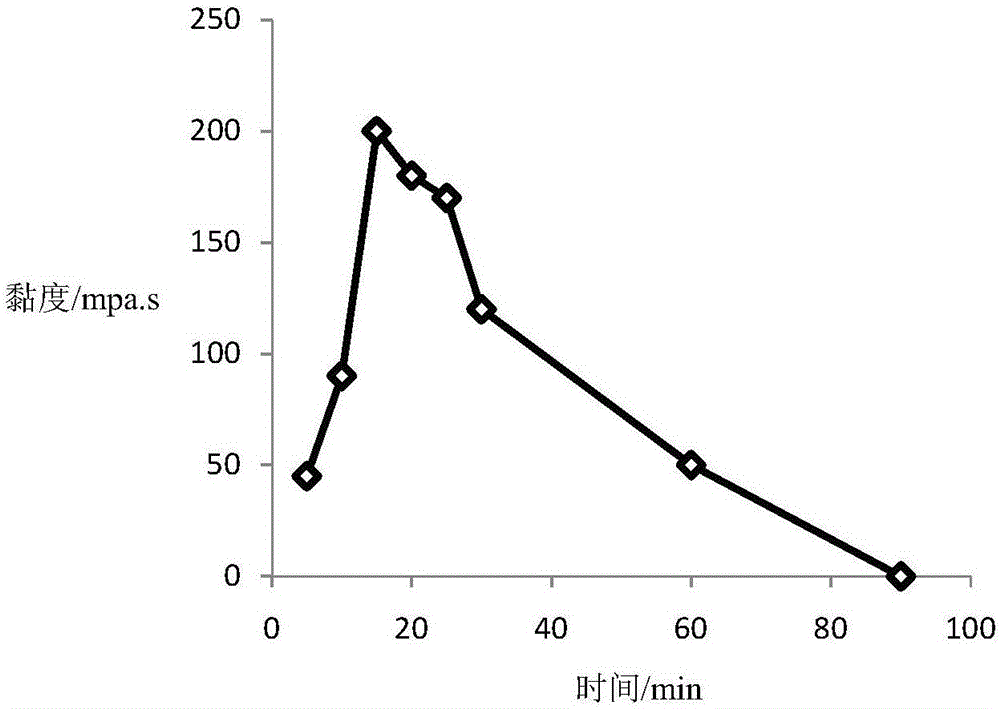

Embodiment 1

[0108] This embodiment provides a compound high temperature resistant viscoelastic self-steering acid, in terms of mass percentage:

[0109] Thickener A: cocamidopropyl betaine 4wt.%;

[0110] Thickener B: erucamide propyl sulfobetaine 2wt.%;

[0111] 31wt.% concentrated hydrochloric acid: 48.4wt.%;

[0112] Corrosion inhibitor: Chloride-1,6-(α-octylpyridine) hexane 3.0wt.%;

[0113] Iron ion stabilizer: iron citrate ion stabilizer 4.5wt.%;

[0114] KCl: 3.5wt.%;

[0115] The balance is water.

[0116] The specific preparation process is:

[0117] According to the above ratio, add cocamidopropyl betaine to water at 25°C to fully dissolve, and cannot be dissolved in acid first, and erucamide propyl sulfobetaine is added to 31% concentrated hydrochloric acid to fully dissolve, cannot be dissolved first into water, then mix the two solutions, add pyridinium quaternary ammonium salt corrosion inhibitor -1,6-(α-octylpyridine) hexane chloride and ferric citrate ion stabilizer,...

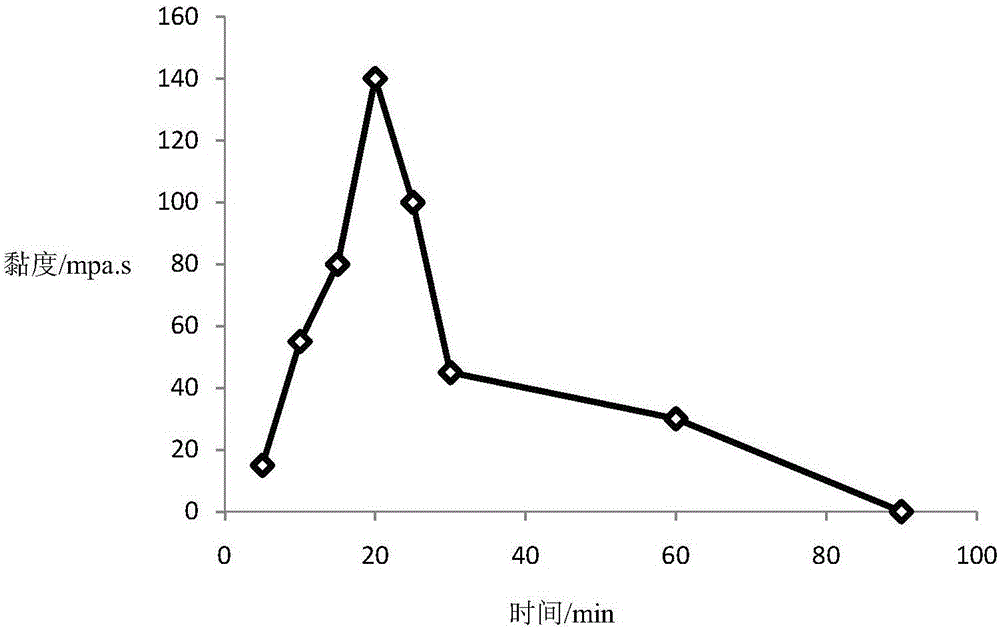

Embodiment 2

[0123] This embodiment provides a composite temperature-resistant viscoelastic self-steering acid, in terms of mass percentage:

[0124] Thickener A: Cocamidopropyl Betaine 4wt.%;

[0125] Thickener B: erucamidopropyl betaine 2wt.%;

[0126] 31wt.% concentrated hydrochloric acid: 65.5wt.%;

[0127] Corrosion inhibitor: oleic acid imidazoline 3.5wt.%;

[0128] Iron ion stabilizer: edetate sodium salt iron ion stabilizer 4%;

[0129] KCl: 3.5wt.%;

[0130] The balance is water.

[0131] The specific preparation process is:

[0132] According to the above ratio, add cocamidopropyl betaine to water at 25°C to fully dissolve it, and cannot dissolve it in the acid solution first; add erucamide propyl betaine to 31% concentrated hydrochloric acid to fully dissolve it, and cannot dissolve it first In the water, mix the two solutions, add imidazoline corrosion inhibitor oleic acid imidazoline and ethylenediaminetetramate sodium salt iron ion stabilizer, stir evenly, and you can g...

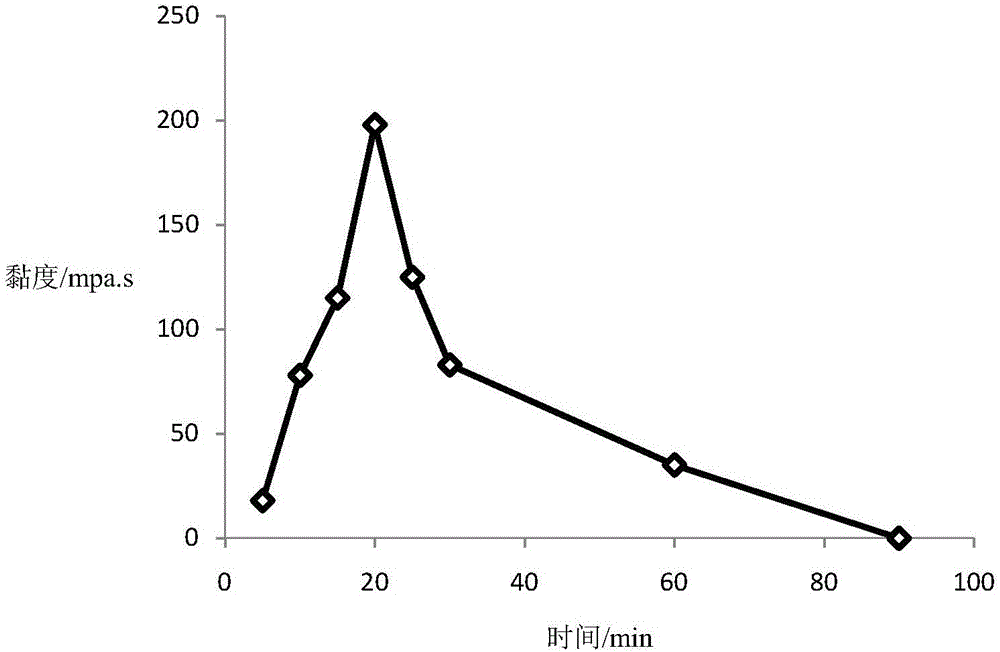

Embodiment 3

[0138] The present embodiment provides a composite temperature-resistant viscoelastic self-steering acid, in mass percent:

[0139] Thickener A: octadecyldimethylhydroxypropyl sulfobetaine 3wt.%;

[0140] Thickener B: erucamidopropyl sulfobetaine 2wt.%;

[0141] 31wt.% concentrated hydrochloric acid: 48.4wt.%;

[0142] Corrosion inhibitor: chloride-1,6-(α-octylpyridine)hexane 3.0wt.%;

[0143] Ferric ion stabilizer: ferric citrate ion stabilizer 4.5wt.%;

[0144] KCl: 2.5wt.%;

[0145] The remainder is water.

[0146] The specific preparation process is:

[0147] According to the above ratio, at 25°C, octadecyldimethylhydroxypropyl sulfobetaine was added to water to fully dissolve, and erucamidopropyl sulfobetaine was added to 31% concentrated hydrochloric acid to fully dissolve. 1,6-(α-octylpyridine) hexane chloride and ferric citrate ion stabilizer are added, and the mixture is evenly stirred to obtain a composite high-temperature resistant viscoelastic Turn to acid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com