Intelligent layered nano foam stabilizer, preparation method thereof and application of intelligent layered nano foam stabilizer in foam flooding

A layered nano-foam flooding technology, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of short foam life, restricting foam flooding efficiency, and limited surface active sites, so as to improve foam Comprehensive performance, enhanced oil recovery, and the effect of improving hydrophilic and hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

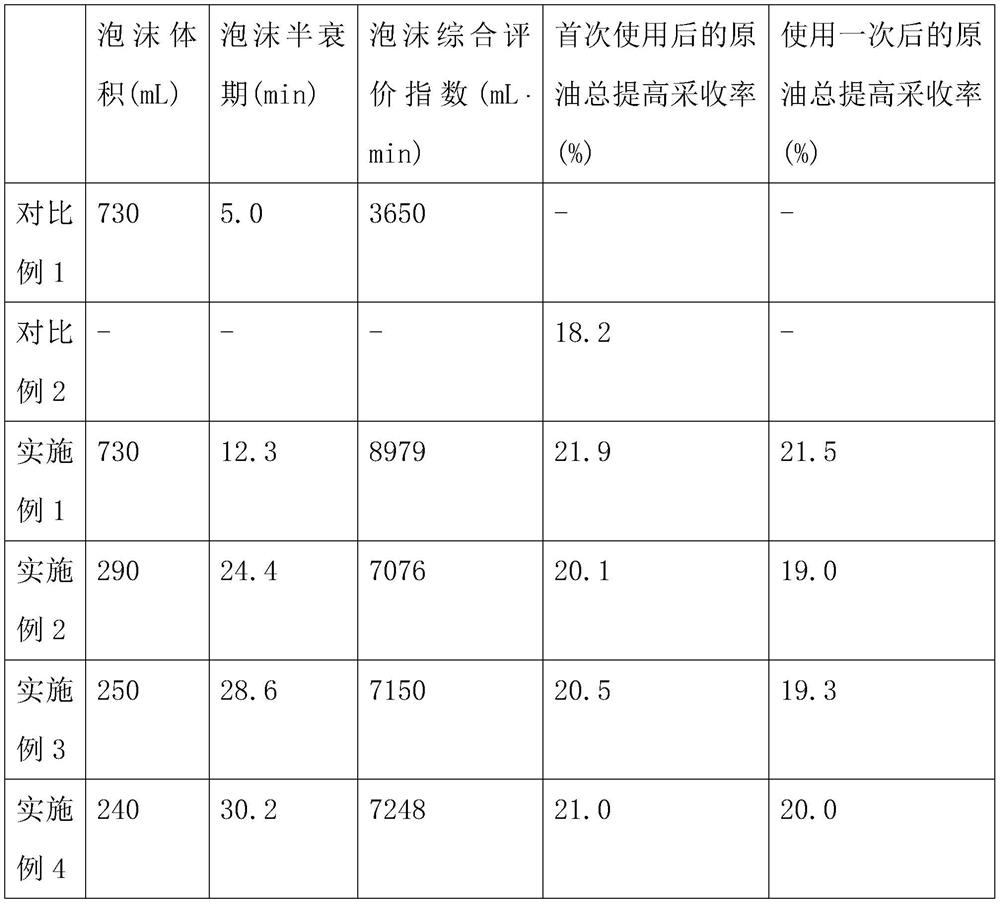

Embodiment 1

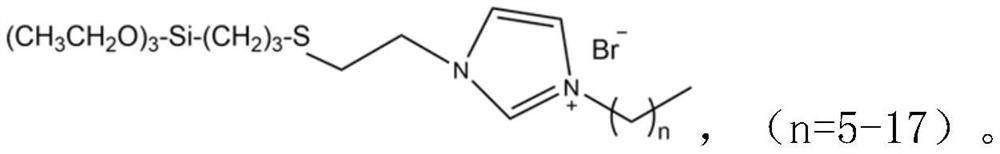

[0027] Intelligent layered nano foam stabilizer, the formula includes: MXene, inorganic substances, alkali source and crosslinking agent, the weight ratio of each component is: 1 part of MXene, 0.1 part of inorganic substance, 0.01 part of alkali source and 0.01 parts of cross-linking agent; MXene is Ti 3 C 2 MXene; Inorganic is NiCl 2 ; the alkali source is sodium acetate; the structure of the cross-linking agent is

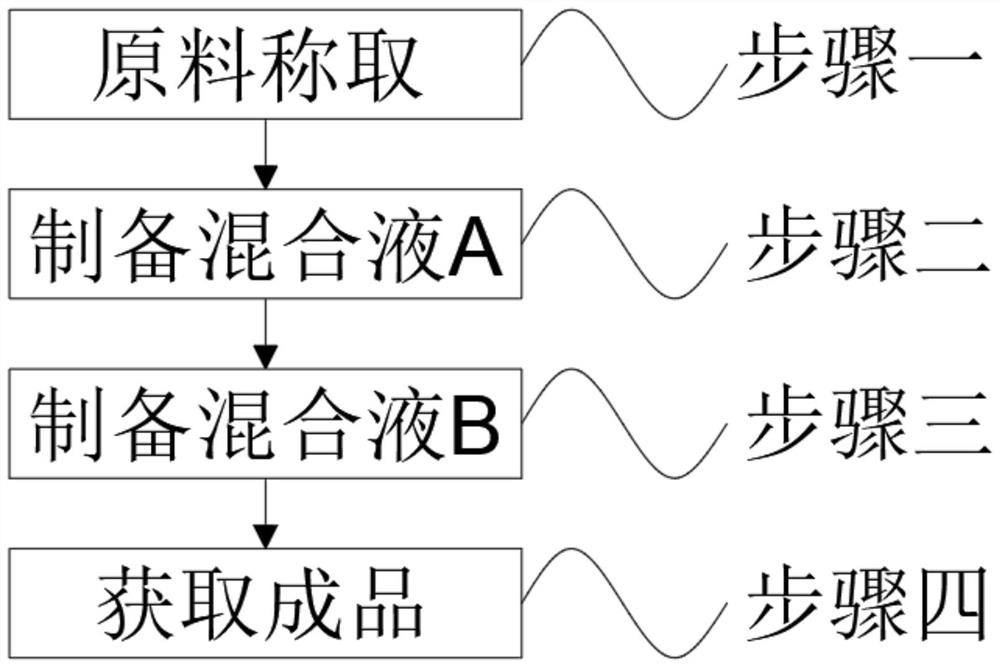

[0028] The preparation method of the intelligent layered nano-foam stabilizer includes step 1, weighing raw materials; step 2, preparing mixed solution A; step 3, preparing mixed solution B; step 4, obtaining finished products;

[0029] Wherein in the above step 1, according to the formula ratio of the intelligent layered nano-foam stabilizer, respectively weigh MXene, inorganic matter, alkali source and cross-linking agent for subsequent use;

[0030] In the above step 2, add the inorganic matter weighed in step 1 into 100mL of deionized water, dissolve it...

Embodiment 2

[0036] Intelligent layered nano foam stabilizer, the formula includes: MXene, inorganic substances, alkali source and crosslinking agent, the weight ratio of each component is: 8 parts of MXene, 1 part of inorganic substances, 0.05 parts of alkali source and 0.1 part of cross-linking agent; MXene is Mo 2 Ti 2 C 3 MXene; Inorganic is NiCl 2 ; the alkali source is sodium acetate; the structure of the cross-linking agent is

[0037] The preparation method of the intelligent layered nano-foam stabilizer includes step 1, weighing raw materials; step 2, preparing mixed solution A; step 3, preparing mixed solution B; step 4, obtaining finished products;

[0038] Wherein in the above step 1, according to the formula ratio of the intelligent layered nano-foam stabilizer, respectively weigh MXene, inorganic matter, alkali source and cross-linking agent for subsequent use;

[0039] In the above step 2, add the inorganic matter weighed in step 1 into 100mL of deionized water, dissol...

Embodiment 3

[0045] Intelligent layered nano-foam stabilizer, the formula includes: MXene, inorganic substances, alkali source and crosslinking agent, the weight ratio of each component is: 5 parts of MXene, 0.2 parts of inorganic substances, 0.04 parts of alkali source and 0.04 parts of cross-linking agent; MXene is W 1.33 CMXene; Inorganic is NiCl 2 ; the alkali source is sodium acetate; the structure of the cross-linking agent is

[0046] The preparation method of the intelligent layered nano-foam stabilizer includes step 1, weighing raw materials; step 2, preparing mixed solution A; step 3, preparing mixed solution B; step 4, obtaining finished products;

[0047] Wherein in the above step 1, according to the formula ratio of the intelligent layered nano-foam stabilizer, respectively weigh MXene, inorganic matter, alkali source and cross-linking agent for subsequent use;

[0048] In the above step 2, add the inorganic matter weighed in step 1 into 100mL of deionized water, dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com