Speed reducer transmission efficiency test system

A technology of transmission efficiency and test system, which is applied in the direction of machine gear/transmission mechanism test, etc., can solve the problems of inaccuracy and universality of the reducer test system, and achieve the effects of convenient docking or separation, improved coaxiality, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

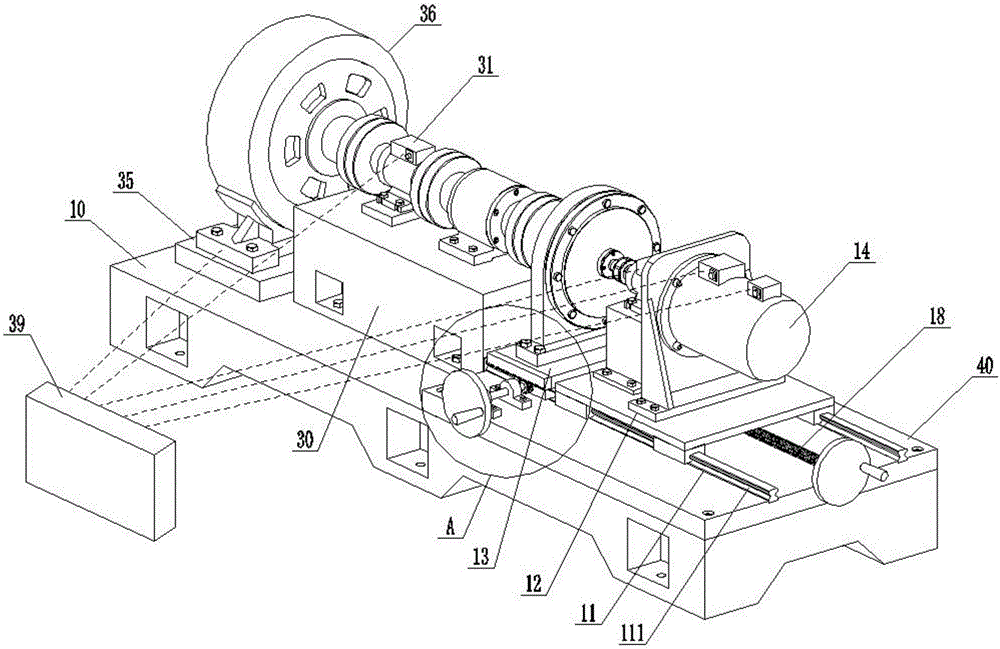

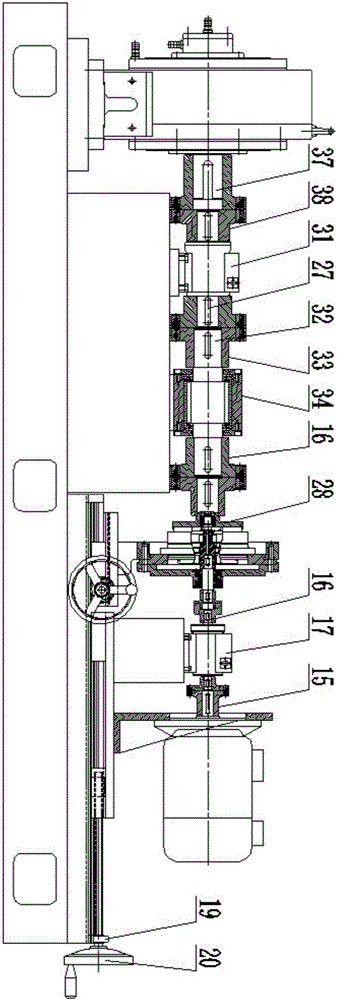

[0030] A transmission efficiency test system for a reducer, such as Figure 1-10As shown, including the base 10, the base 10 is provided with an anti-vibration pad 40, the anti-vibration pad 40 is fixedly connected with the base 10 by bolts, and at least one guide rail 11 is provided on the end surface of the anti-vibration pad 40, and the base 10 of this embodiment is provided with Two guide rails 11, rail grooves 111 are provided on both sides of the guide rail 11, a motor bracket 12 and a reducer bracket 13 are arranged on the guide rail 11, the motor bracket 12 and the reducer bracket 13 share the same guide rail 11, the motor bracket 12 and the reducer bracket 13 all slide on the guide rail 11, and the speed reducer tested in this embodiment is an RV speed reducer.

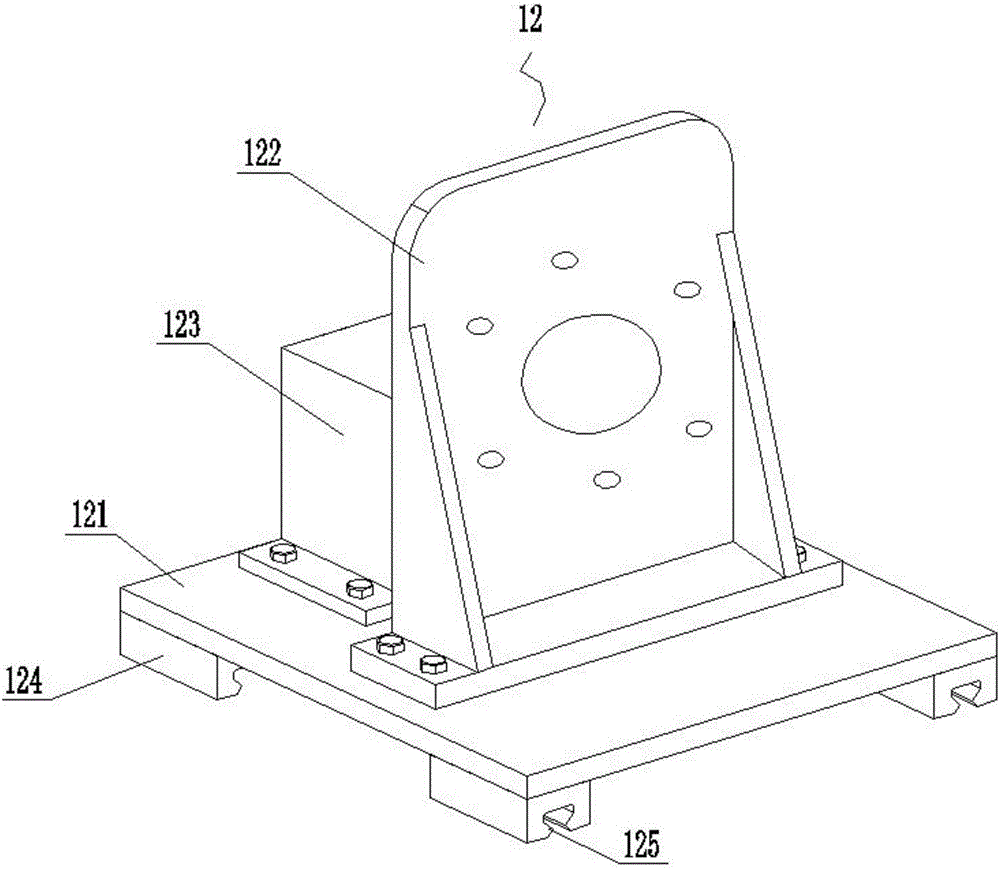

[0031] The motor bracket 12 includes a first moving plate 121 and a first supporting seat 122 fixed on the first moving plate 121. A motor 14 is fixed on the first supporting seat 122. The motor 14 is a varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com