A cross slider compression mechanism

A compression mechanism and cross-slide technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of many compressor components, damage to the sliding surface, increased clearance, etc., to reduce the difficulty of assembly and debugging, The effect of resolving shocks and reducing the number of

Inactive Publication Date: 2014-04-16

国营第一二四厂

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, first of all, this type of compressor has many components and a complex structure; secondly, the processing and manufacturing of the frame is more difficult; thirdly, the wear between the frame and the slider during work will cause the gap to increase, causing the two to produce impact and make the sliding Surface damage and additional noise, these problems have always been unavoidable for cross slide compressors, affecting the reliability and efficiency of compressor work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

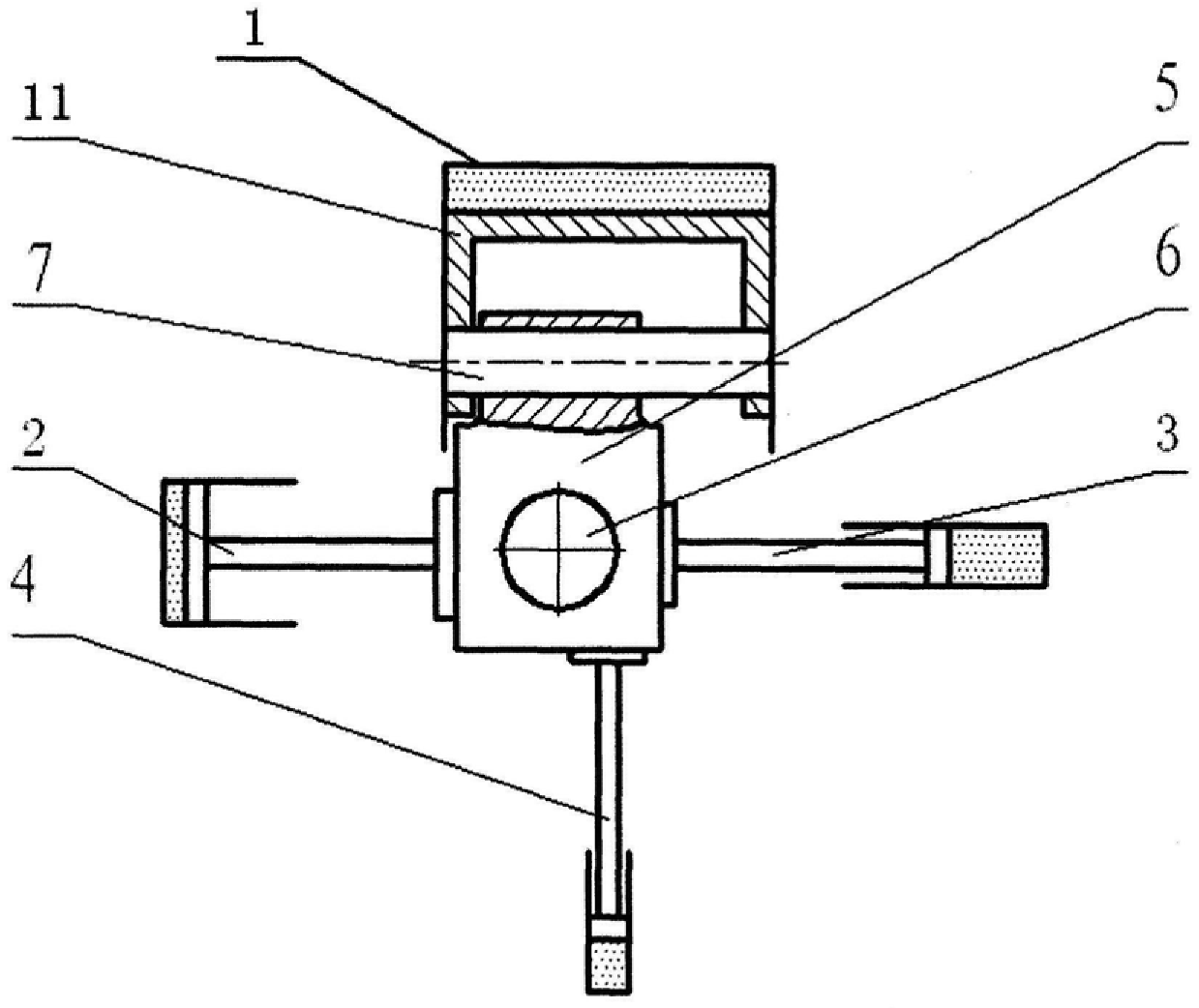

The present invention is an Oldham compression mechanism, which includes a piston and a compression cylinder. It is characterized in that: the mechanism has a slider, which is connected to the crankshaft through a crank pin and moves, and is installed in both horizontal and vertical directions of the slider. A compression mechanism that is matched by a piston and a compression cylinder. There are 4 compression mechanisms in total. The piston of each compression mechanism can slide back and forth along its installation plane. The four-stage compressor, the third-stage compressor, the piston in the first-stage compressor is slidingly connected with the slider through the piston pin, and the piston areas of the first-stage compressor, the second-stage compressor, the third-stage compressor, and the fourth-stage compressor are successively reduced. Small. Compared with the prior art, the technical solution of the present invention reduces the number of parts, reduces the difficulty of assembling and debugging the compressor, and solves the problems of impact, noise and the like caused by the increased gap after wear.

Description

A cross slider compression mechanism technical field The invention relates to a cross slider compression mechanism, which belongs to the technical field of product structure. It is suitable for the environment requiring high reliability, small installation volume and high pressure. Background technique At present, a common cross slide compressor is composed of a crankshaft, a slider, a frame (including a slideway and a piston), a balance weight, a crankcase, and a compression cylinder. When the crankshaft of the cross slider compressor rotates, the crank pin makes the slider slide up and down and left and right in the frame at the same time, so that the rotary translation of the slider is converted into the reciprocating motion of the frame, and the piston rod fixed on the frame pushes the piston to reciprocate Movement to complete the working process of the compressor. However, first of all, this type of compressor has many components and a complex structure; secondly, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F04B39/00

Inventor 谷万淼陈强刘家旺任燏基

Owner 国营第一二四厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com