A Dual Plane Probe Deflection Composite Imaging Method

A composite imaging, dual-plane technology, applied in image data processing, 2D image generation, medical science, etc., can solve the problems of increased patient pain, no vertical puncture imaging device, large puncture distance, etc., to reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

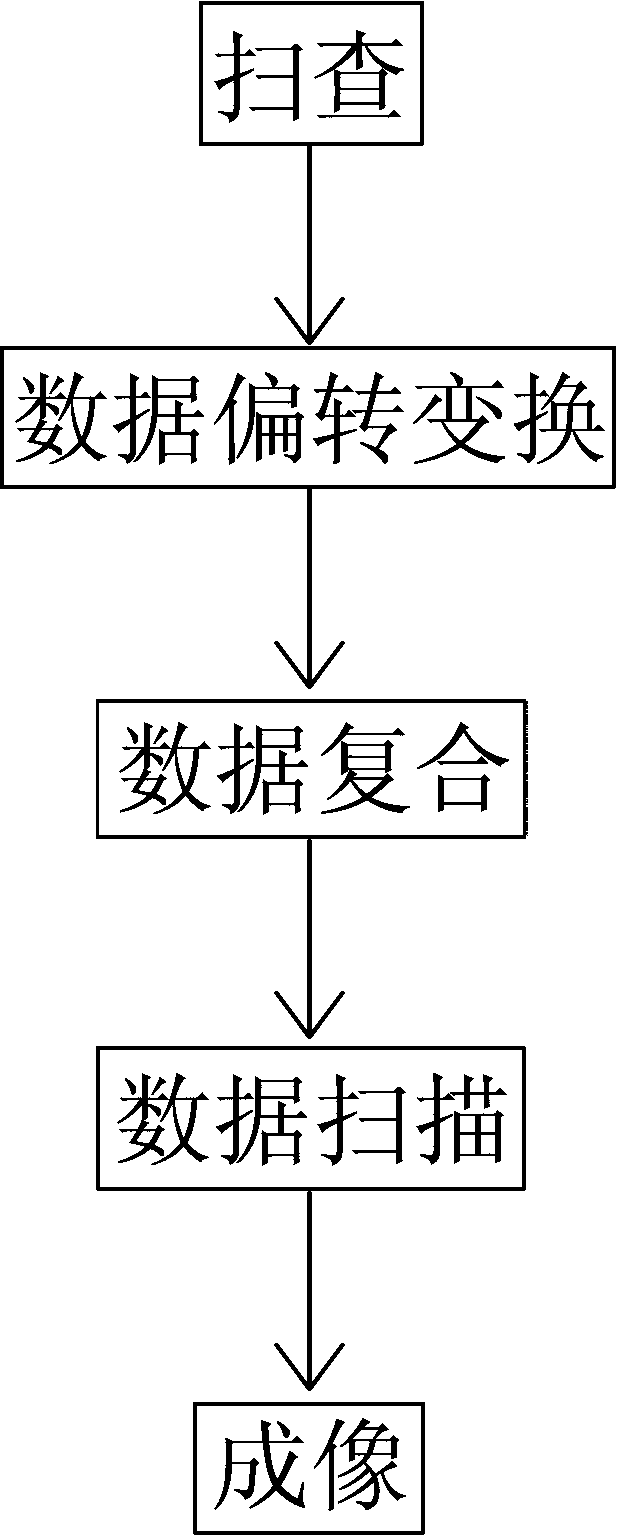

[0030] like figure 1 As shown, this dual-plane probe deflection compound imaging method includes the following steps:

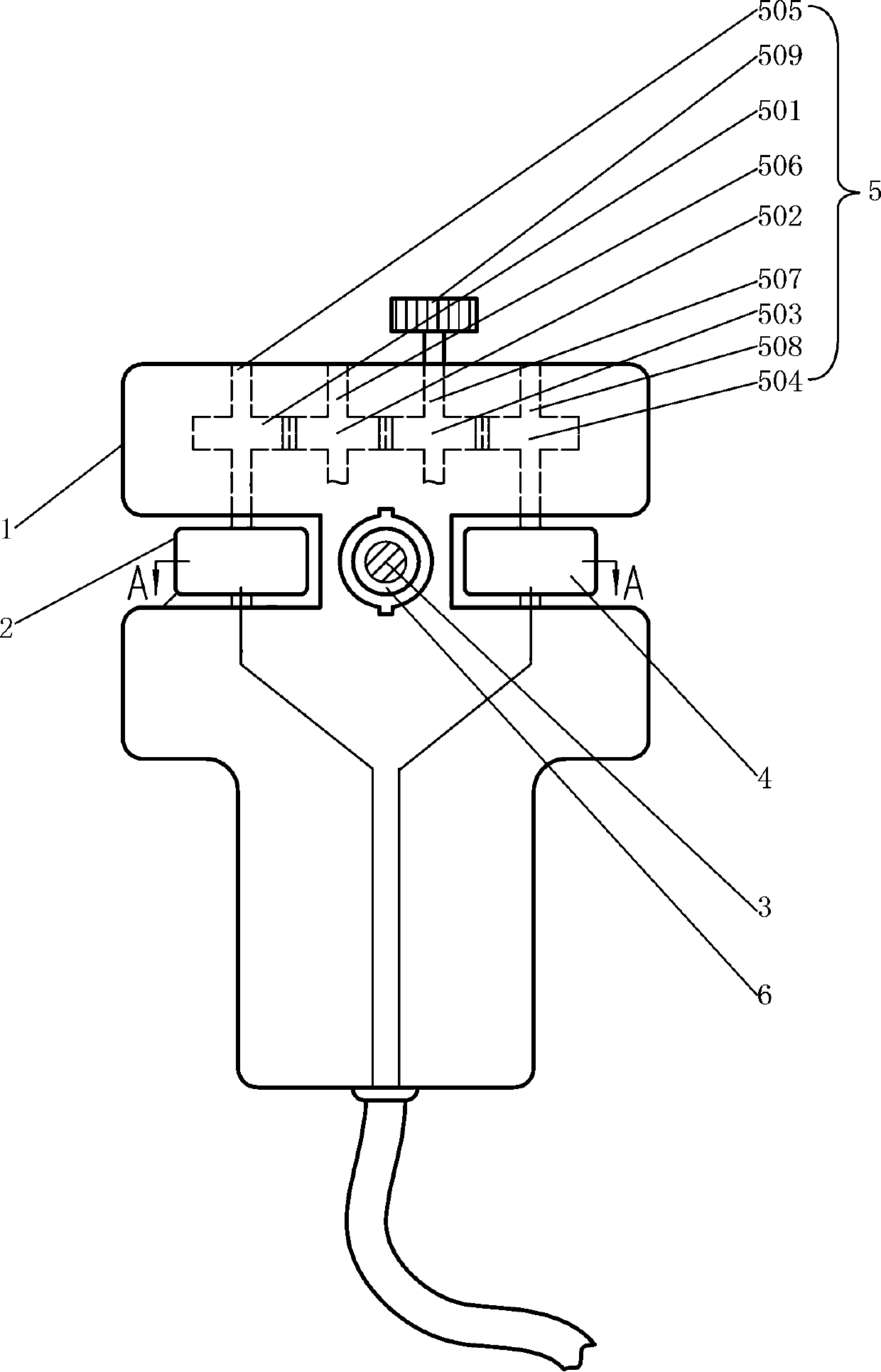

[0031] (1) Use dual-plane probes for scanning: the first-plane ultrasonic probe and the second-plane ultrasonic probe conduct deflection scans respectively, covering the puncture target and the puncture needle;

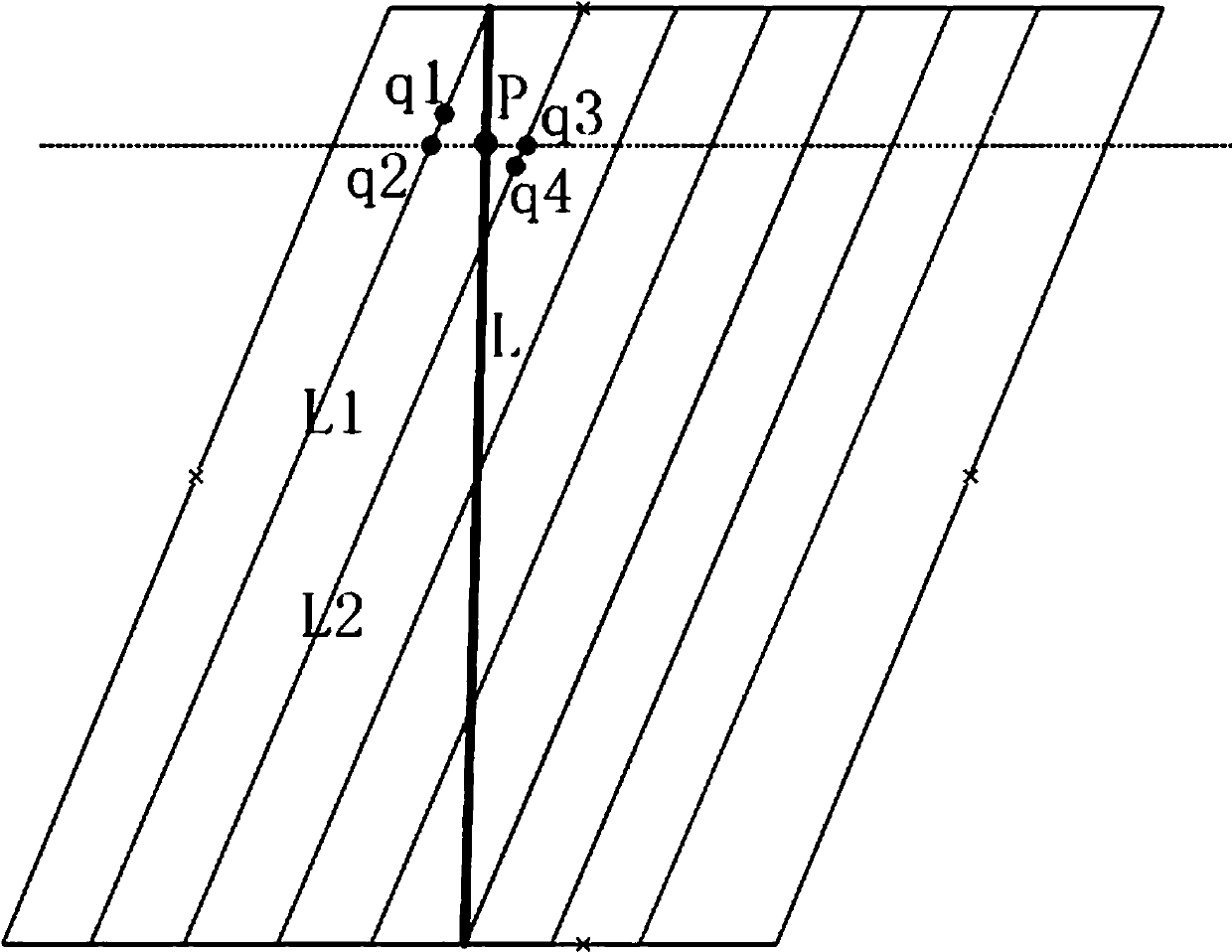

[0032] (2) Data deflection transformation: Transform the original data beams obtained by the first plane ultrasonic probe and the second plane ultrasonic probe into deflected data beams respectively; the first plane ultrasonic probe and the second plane ultrasonic probe convert the original data according to the following steps Transform the harness into a deflection data harness:

[0033] (2-1) Select the original data harness B, which has a deflection angle with the vertical direction;

[0034] (2-2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com