Double-station dispensing machine used for LCD (Liquid Crystal Display) and dispensing method thereof

A liquid crystal display and double-station technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems affecting the production efficiency of LCD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

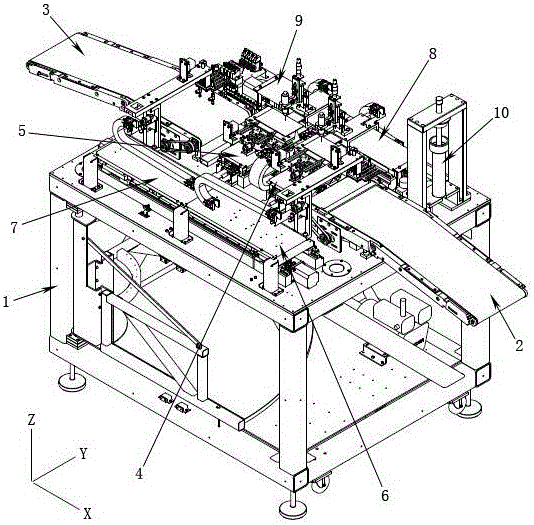

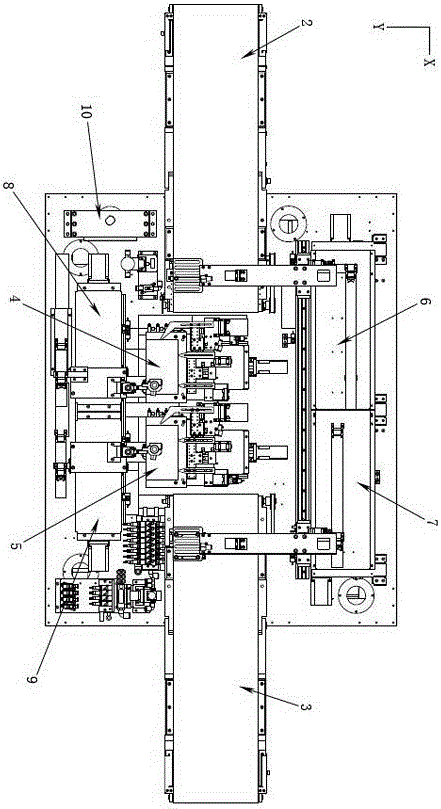

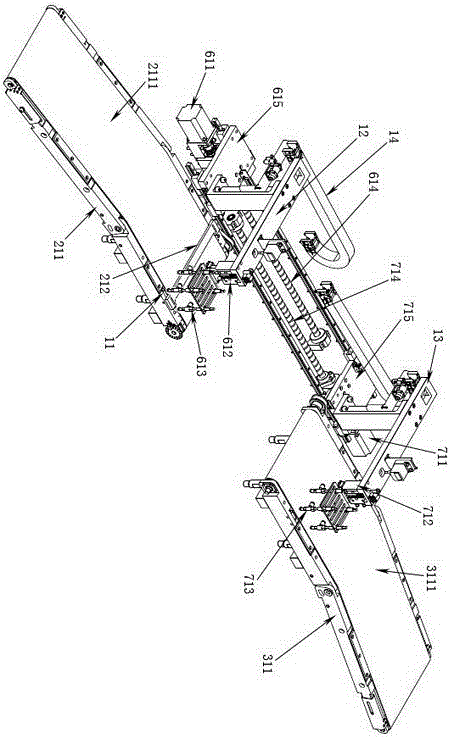

[0041] Example: such as figure 1 and figure 2 Shown, a kind of duplex dispensing machine for LCD liquid crystal display includes frame 1, and the duplex dispensing machine for LCD liquid crystal display also includes the X that is arranged on one end of frame 1 The material input assembly 2 in the axial direction, the material output assembly 3 in the X-axis direction arranged on the other end of the frame 1, the material output assembly 3 in the X-axis direction arranged on the frame 1 and located between the material input assembly 2 in the X-axis direction and the material output assembly 3 in the X-axis direction Y-axis direction dispensing platform component 1 4 and Y-axis direction dispensing platform component 2 5, X-axis direction feeding component 1 6 and X-axis direction feeding component 2 7 set on the frame 1 Dispensing needle assembly 1 in the X-axis direction, dispensing needle assembly 2 in the X-axis direction 9, and the rubber storage barrel assembly 10 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com