Intelligent grabbing manipulator for automotive green tires

A technology for grabbing manipulators and automobile tires, which is applied to conveyor objects, transportation and packaging, etc. It can solve problems such as operational errors, easy damage to tire embryos, low output, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

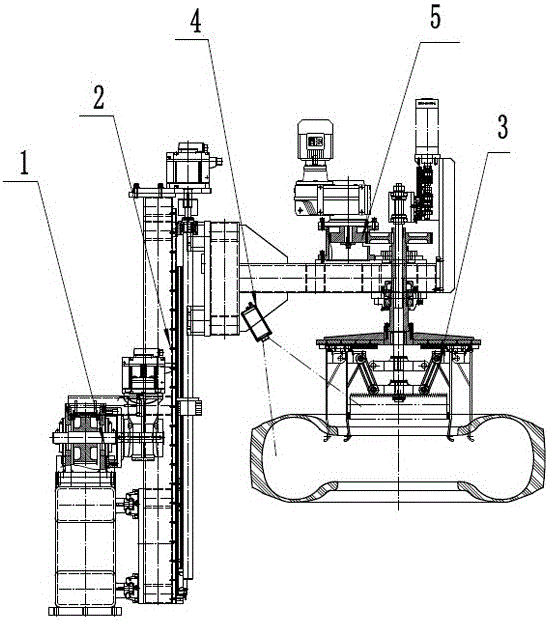

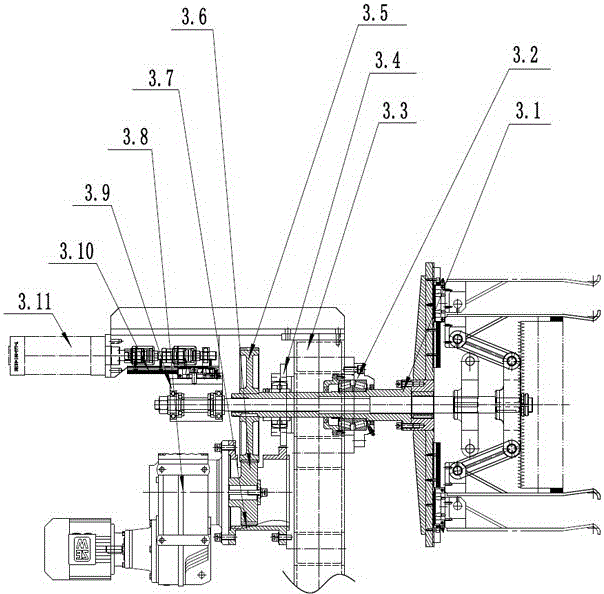

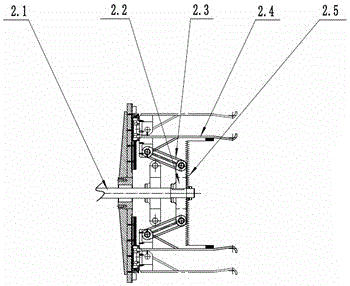

[0026] see Figure 1~4 , the invention relates to an intelligent grabbing manipulator for automobile tire blanks, which includes a manipulator jaw expansion and contraction mechanism 3 and a manipulator rotation and positioning mechanism 5, and the manipulator jaw expansion and contraction mechanism 3 includes a moving inner shaft 2.1, which moves The inner shaft 2.1 passes through a flange 2.6, and one end of the moving inner shaft 2.1 is fixedly connected with a connecting rod support frame 2.2, and the flange 2.6 is provided with a plurality of linear guide rail pairs 2.7 along its radial direction, and claws 2.4 is fixedly connected to the slider of the first linear guide rail pair 2.7, one end of the connecting rod 2.3 is hinged with the connecting rod support frame 2.2, and the other end is hinged with the claw 2.4 or the slider on the first linear guide rail pair 2.7, and the dust cover 2.5 is set on the moving inner shaft 2.1, and the edge of the dust cover 2.5 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com