A snap cover device with positioning star wheel

A star wheel and cap closure technology, which is applied in the field of cap closure devices with positioning star wheels, can solve the problems of non-magnetic cans that cannot be positioned, and achieve the effects of improving the efficiency of cap closure, smooth cap feeding, and multi-cap closure matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

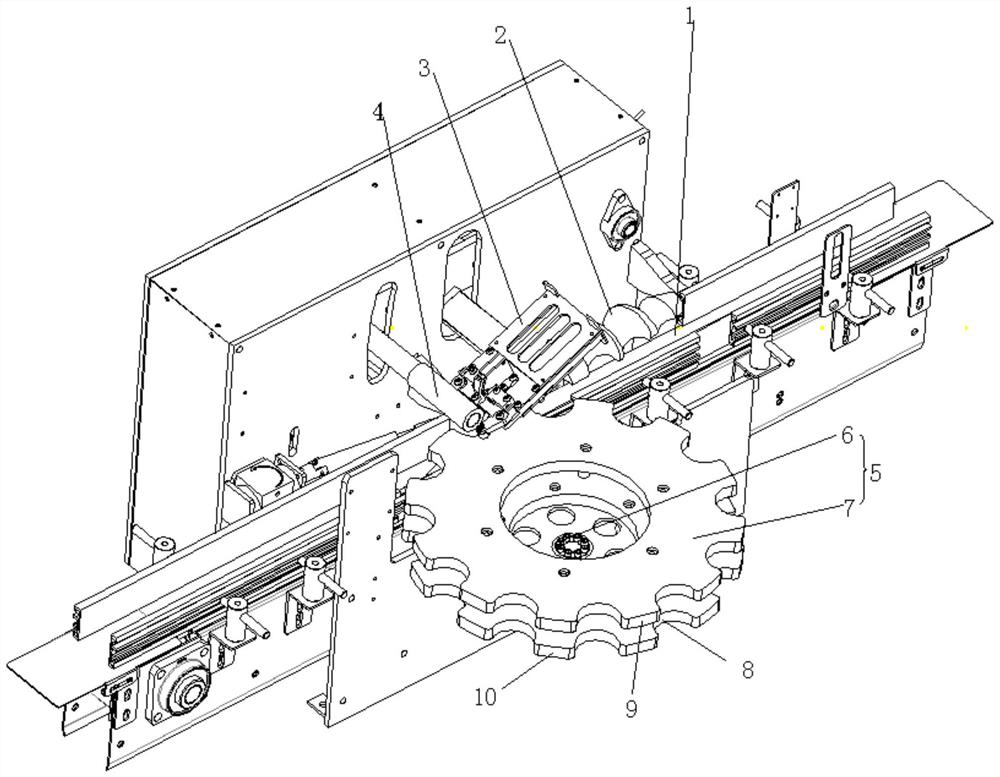

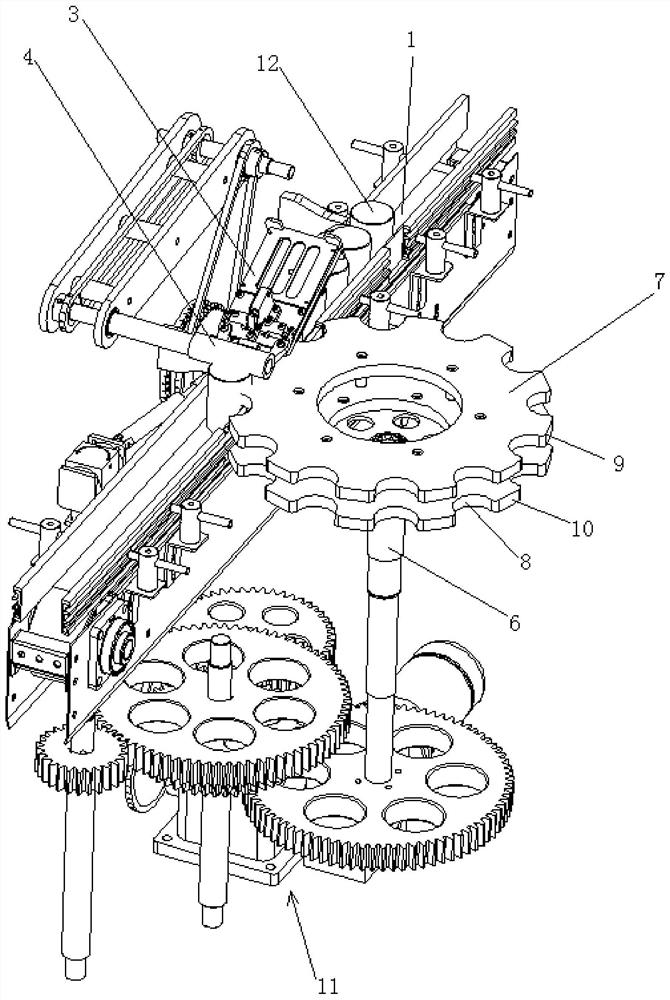

[0022] Such as Figure 1~2 As shown, a cap buckle device with a positioning star wheel includes a positioning star wheel 5, and the positioning star wheel 5 includes a rotating shaft 6 and a star wheel 7, and the star wheel 7 is fixed on the rotating shaft 6; The edge of the wheel 7 is provided with several grooves 8, which are matched with the tank body 12 to be buckled. The star wheel 7 can carry out orderly positioning of the tank body 12 to be capped on the running water, so that the positioning of the tank body 12 is accurate, and the efficiency of accurately capping is improved.

[0023] Further, it also includes a transmission part 1 and a distance-dividing screw 2, the transmission part 1 is a mesh chain, and the distance-dividing screw 2 and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com