Rail vehicle brake disk

A technology for rail vehicles and brake discs, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as the inability to use rail vehicles, and achieve the effects of improved operational reliability, cost advantages, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

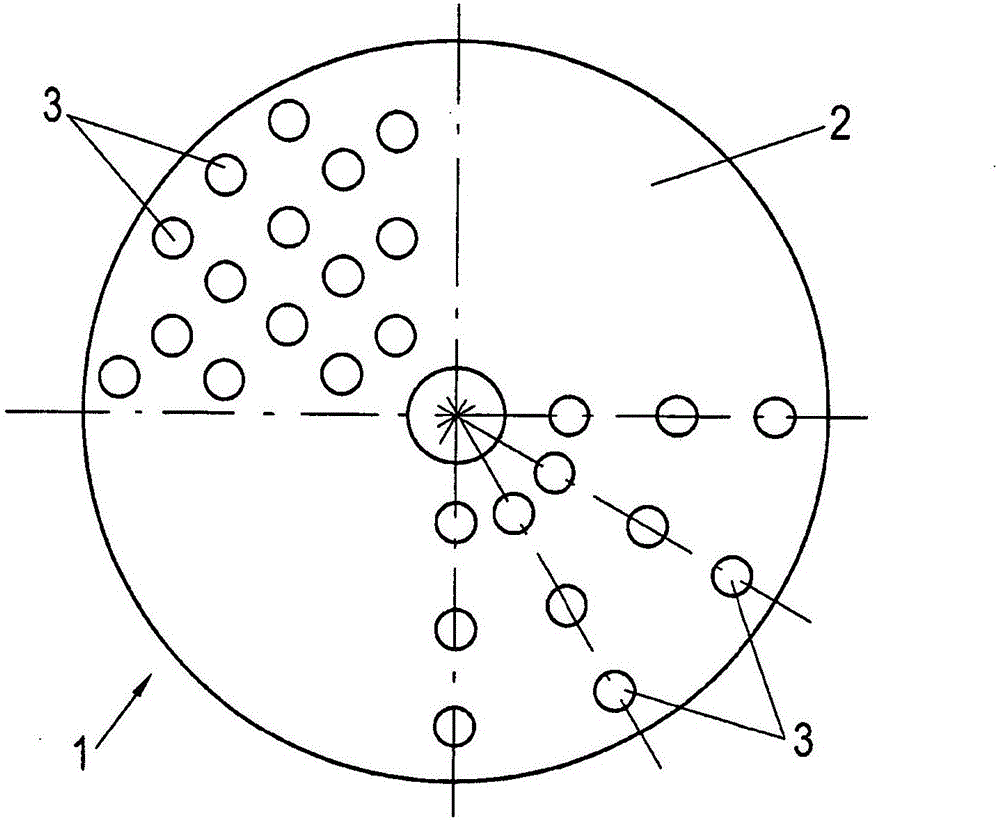

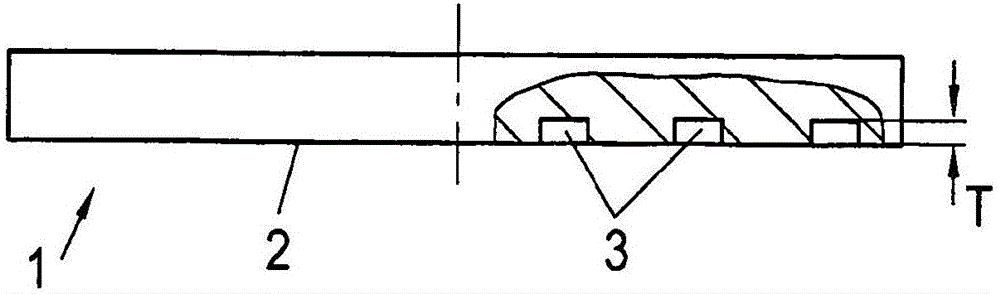

[0027] The drawing shows a one-piece brake disk 1 of steel or cast iron for a rail vehicle, which has an active surface 2 against which a friction body rests during braking.

[0028] According to the invention, the effective face 2 is provided with a plurality of blind openings, which are figure 1 and 2 In the exemplary embodiment shown, this is formed by a blind hole 3 .

[0029] exist figure 1 A substantially haphazard arrangement of blind holes 3 is shown in , as an arrangement possibility, to be precise in the upper left quarter of a circle.

[0030] An ordered positioning of the blind holes 3 can be seen in the lower right quarter of the circle, in which they are oriented not only radially but also multiple concentrically.

[0031] The depth T of the blind hole 3 corresponds here to the maximum permissible amount of wear of the active face 2 .

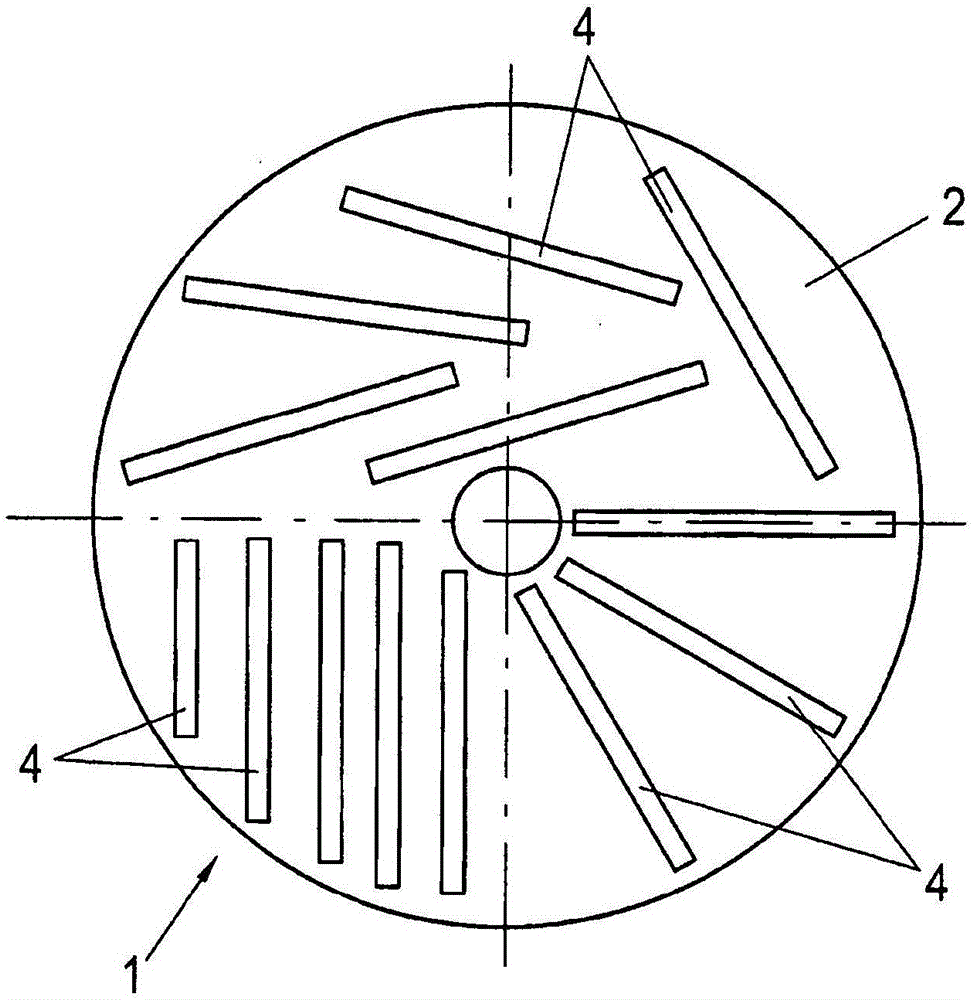

[0032] this is also image 3 and 4 Shown in the example of the invention shown, wherein, blind opening is configured as gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com