Preparation method of easy-to-degrade adipic acid polyethylene glycol polyester

A technology of polyethylene glycol polyester and polyethylene glycol, which is applied in the field of preparation of easily degradable adipic acid polyethylene glycol polyester, can solve the problems of ethylene glycol loss and difficulty in molecular weight, and achieves improved efficiency. efficiency, cost reduction, and product appearance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

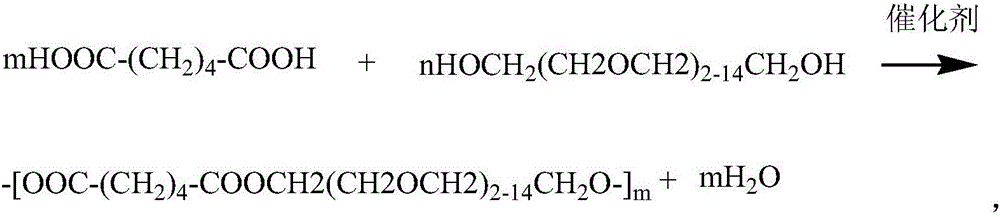

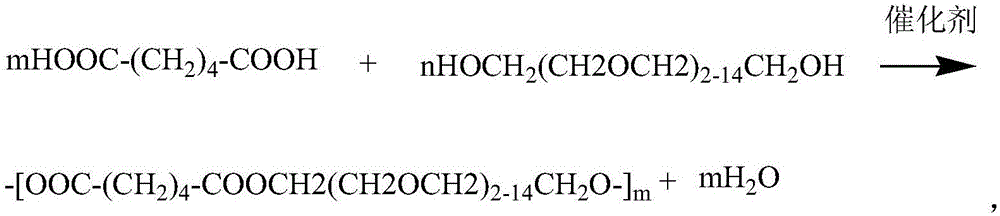

[0028] In the preparation method of this embodiment, the esterification reaction equation is:

[0029]

[0030] m:n=1:1-2.

[0031] For compounding, add the remaining polyethylene glycol by adding while stirring.

Embodiment 1

[0033] Add 528 grams of polyethylene glycol with a molecular weight of 528 and 146 grams of adipic acid to the flask and add 1.3 grams of p-toluenesulfonic acid and 0.4 grams of phosphorous acid catalyst under stirring. The temperature is raised to 135°C in 4 hours, and the resulting product is removed in time by vacuum -0.096MPa Water, after keeping the temperature at 135-140℃ for 3 hours, cooling to 80℃, adding 264 grams of polyethylene glycol, stirring at 70-80℃ for 1 hour to obtain a light yellow color (color less than 50 platinum cobalt standard) Transparent product. This embodiment has reasonable process, simple operation, stable product, excellent smooth diffusion and lubricity, good isolation and demoulding effect, and easy biodegradability.

[0034] Take 50ml of an aqueous solution with a product concentration of 10% and put it in a 250ml Erlenmeyer flask, add 25% of the inoculation amount, shake it at 30°C for 5h, measure COD, and calculate the degradation rate of 58.2%....

Embodiment 2

[0038] Add 528 grams of polyethylene glycol with a molecular weight of 528 and 146 grams of adipic acid to the flask and add 1.3 grams of p-toluenesulfonic acid and 0.4 grams of phosphorous acid catalyst under stirring. The temperature is raised to 135°C in 4 hours, and the resulting product is removed in time by vacuum -0.096MPa After holding water for 3 hours under the reaction conditions of 135-140℃, the temperature is lowered to 80℃, adding 422 grams of polyethylene glycol, stirring at 70-80℃ for 1 hour to obtain a slightly yellow color (color less than 50 platinum cobalt standard) Transparent product. This embodiment has reasonable process, simple operation, stable product, excellent smooth diffusion and lubricity, good isolation and demoulding effect, and easy biodegradability.

[0039] Take 50ml of an aqueous solution with a product concentration of 10% and put it in a 250ml Erlenmeyer flask, add 25% of the inoculation amount, shake it at 30°C for 5h, measure COD, and calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com