Preparation method of modified polyethylene glycol adipate

A technology of polyethylene glycol ester and polyadipate, which is applied in the field of preparation of modified polyethylene adipate, can solve the problems of difficulty in improving biodegradability, and achieve simple equipment, mild reaction conditions, The effect of saving equipment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

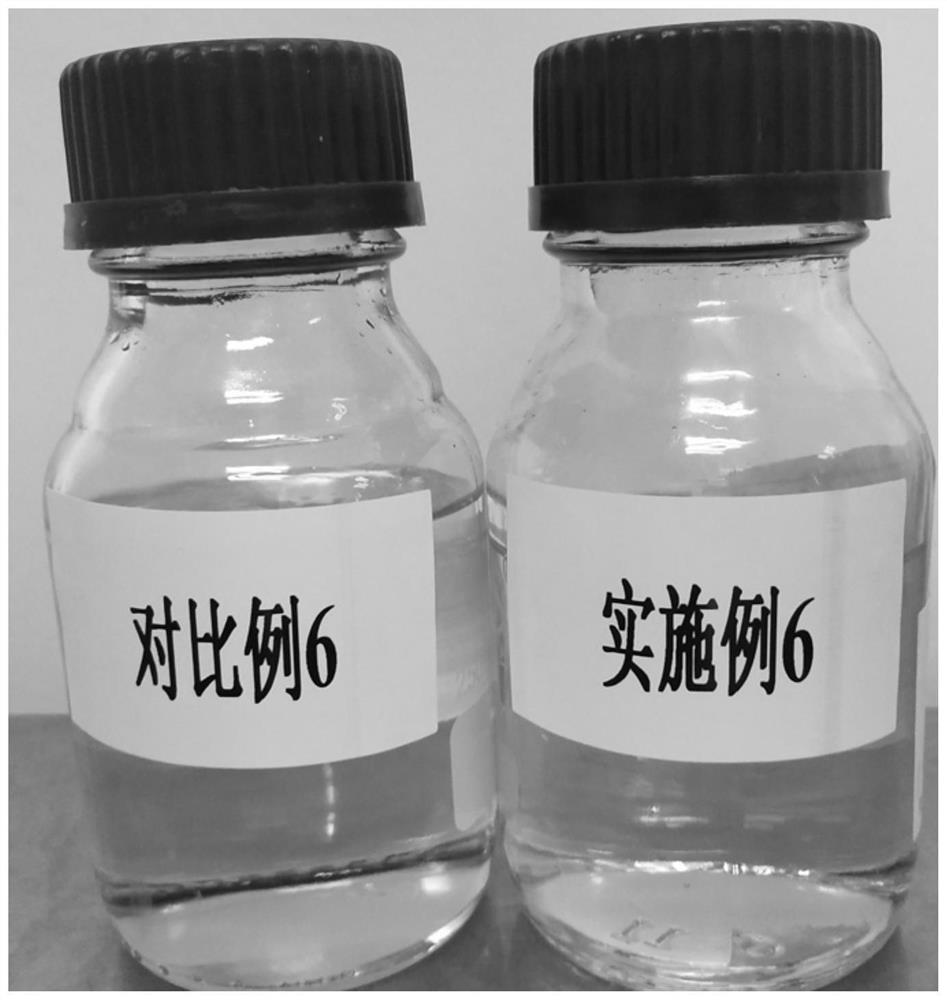

Image

Examples

preparation example Construction

[0025] A preparation method of modified poly(ethylene glycol adipate), which comprises the following steps: adding lactic acid to polyethylene glycol at a molar ratio of polyethylene glycol: lactic acid=1.5 to 3.0:1, and adding under stirring Catalyst, heat up; remove the generated water under vacuum conditions of 600-700mbar, keep warm at 80-85°C for 1-2h, heat up to 100-120°C within 3-4h, keep warm for 1-3h; according to adipic acid: lactic acid = Add adipic acid at a molar ratio of 1.0 to 2.0:1, keep warm for 1 to 3 hours at a temperature of 160 to 165°C, adjust the vacuum to less than 10mbar, keep warm for 2 to 5 hours, and then cool down to 75 to 80°C, that is A modified polyethylene adipate was obtained.

[0026] In the above method, the molecular weight of polyethylene glycol is 200-600; the lactic acid is L-lactic acid; the catalyst is a mixture of methanesulfonic acid and phosphorous acid, wherein the weight ratio of methanesulfonic acid and phosphorous acid is 1:0.05...

Embodiment 1

[0030] Add 900 grams of polyethylene glycol with a molecular weight of 600 in the flask, add a catalyst of 90 grams of lactic acid, 5.0 grams of methanesulfonic acid and 0.7 grams of phosphorous acid under stirring, slowly heat up, if the temperature rises too quickly, the reaction will be violent. Lactic acid will come out at 650 mbar Remove the generated water in time under vacuum conditions, keep warm at 80°C for 2 hours, raise the temperature to 110°C in 3 hours, and keep warm for 2 hours; cool down to 100°C, add 146 grams of adipic acid that has been weighed using a high-level funnel, and put it at a temperature of 160°C After heat preservation for 2 hours under the reaction condition of -165°C; vacuum condition to a maximum of 10mbar, carry out polycondensation and heat preservation for 4 hours, then cool down to 80°C to obtain a slightly yellow (color less than 50 platinum-cobalt standard) transparent product, and its acid value was measured 2.1mgKOH / g, dynamic viscosity...

Embodiment 2

[0036] Add 1100 grams of polyethylene glycol with a molecular weight of 500 in the flask, add a catalyst of 90 grams of lactic acid, 4.1 grams of methanesulfonic acid and 0.6 grams of phosphorous acid under stirring, slowly heat up, if the temperature rises too quickly, the reaction will be violent. Lactic acid will come out at 650mbar Remove the generated water in time under vacuum conditions, keep warm at 80°C for 2 hours, raise the temperature to 110°C for 3 hours, and keep warm for 1 hour; cool down to 100°C, add 190 grams of adipic acid that has been weighed using a high-level funnel, and heat at 160°C After 3 hours of heat preservation under the reaction condition of -165°C; vacuum conditioning to a maximum of 10mbar for polycondensation, after 4 hours of heat preservation, the temperature was lowered to 80°C to obtain a slightly yellow (color less than 50 platinum-cobalt standard) transparent product, and its acid value was measured It is 2.2mgKOH / g, and its dynamic visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com