A protection method for the inner lining of the Hismelt process smelting reduction furnace

A reduction furnace and furnace lining technology, applied in the protection field of HIsmelt process smelting reduction furnace lining, can solve the problems of large consumption, short service life, expensive refractory materials, etc., to reduce erosion and erosion, reduce production costs, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

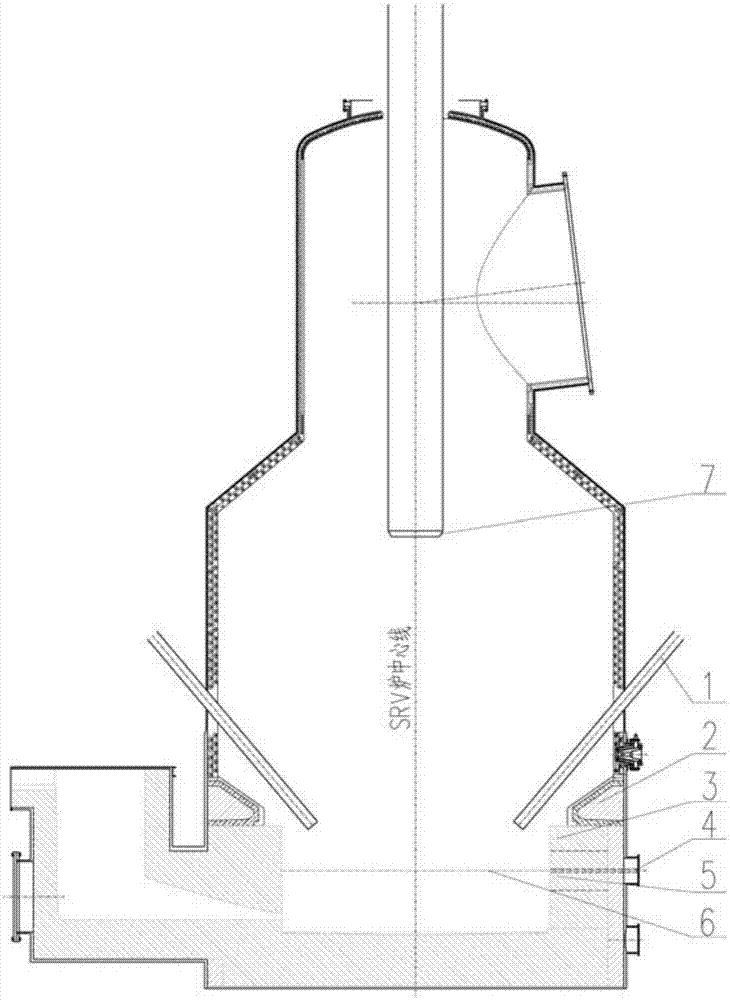

[0021] Add the slagging agent of titanium-containing material into the solid material spray gun equipment 1, and use N 2 Injected into the SRV furnace with a blowing flow rate of 75t / h, the TiO in the titanium-containing material 2 Under the high-temperature reducing atmosphere in the SRV furnace, it melts in the high-temperature slag-iron, and forms a mixture phase of TiC, TiN and solid solution Ti(C,N) and slag in the slag-iron in the slag-iron interface 6 and above. , TiC and TiN have very high melting points, pure TiC is 3150°C, and TiN is 2950°C. No matter in the slag phase or in the molten iron phase, Ti(C,N) exists as tiny solid particles, making the liquid phase Viscosity increased significantly, and the high-viscosity mixture phase was sprayed by hot air spray gun 7 and high-speed N 2 The formed airflow splashes onto the lining surface of the SRV furnace, and the total time for the solid material containing slagging agent to be sprayed into the SRV furnace is 100 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com