Patents

Literature

33results about How to "Reduce scour erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

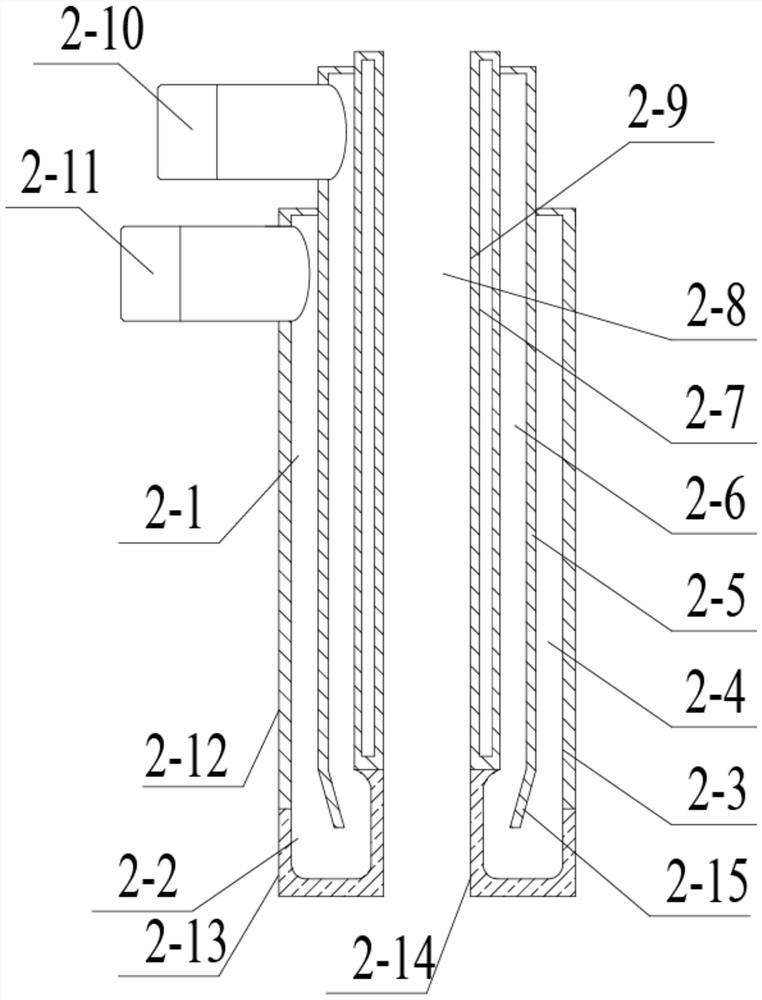

Method for simulating soil slope instability induced by groundwater

InactiveCN108828189AShorten test timeImprove test efficiencyEarth material testingPhysical modelInstability

The invention discloses a method for simulating soil slope instability induced by groundwater. The method is characterized by comprising the following steps: a, putting a physical model on a centrifugal machine; b, raising the height of an external water tank, opening a water outlet valve and a water inlet valve, carrying out water seepage into a soil layer according to the thickness of a saturated soil layer and completing the saturation process of a soil mass; c, closing the water inlet valve, reducing the height of the external water tank, improving the centrifugal acceleration to solidifyand disperse the internal pore water pressure of the physical model; d, after the solidification is finished, opening the water inlet valve, raising the height of the external water tank to the corresponding height according to the preset water level height of an internal water tank; obtaining different infiltration capacity of the water to the slope when the water in the internal water tank seepsinto the soil layer and stays at different heights, and observing the wetting front change and the slope deformation condition of the physical model. The method disclosed by the invention has the advantages that the height of the groundwater level can be accurately adjusted in real time and washing of water current to the slope body is prevented; in the whole test process, high operability, highreliability and good test effect are realized.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

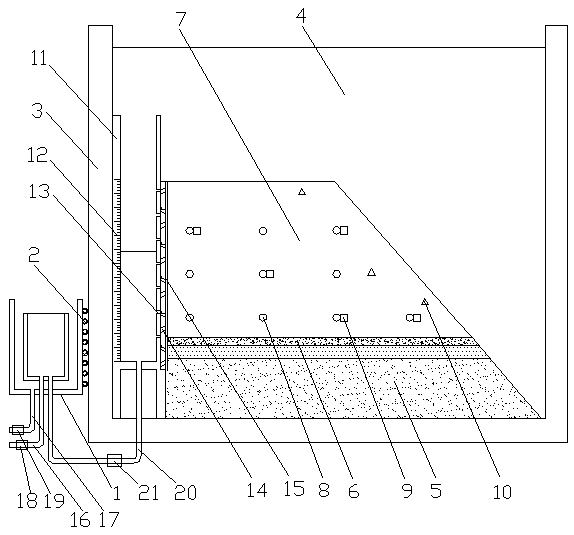

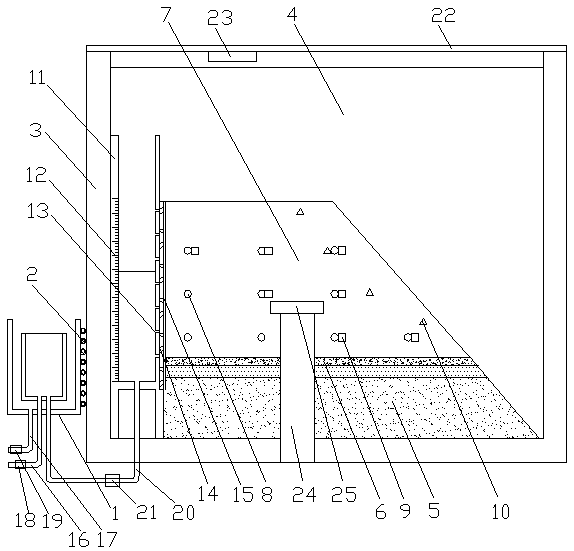

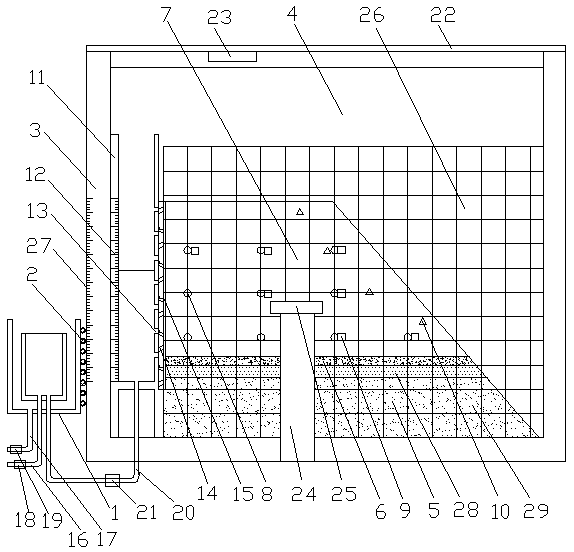

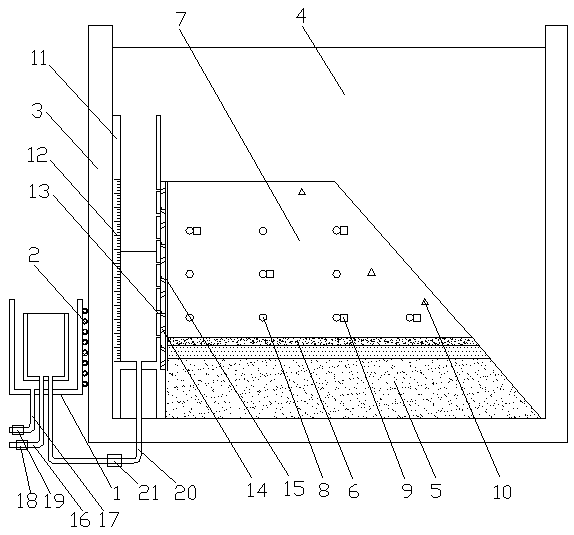

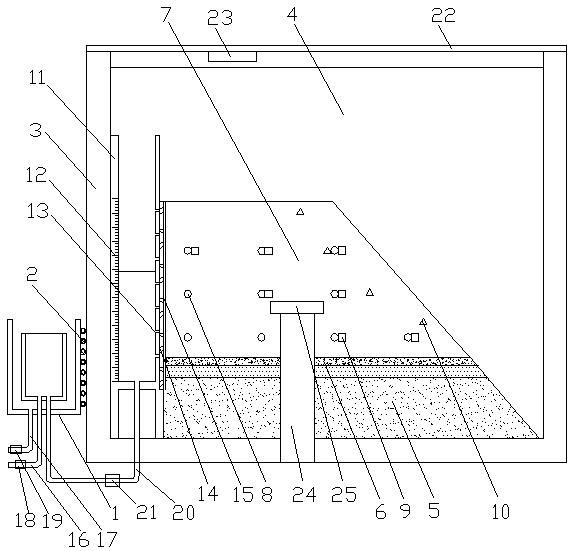

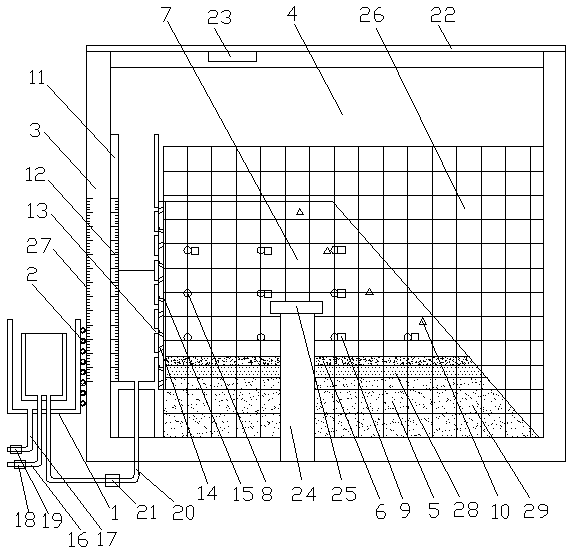

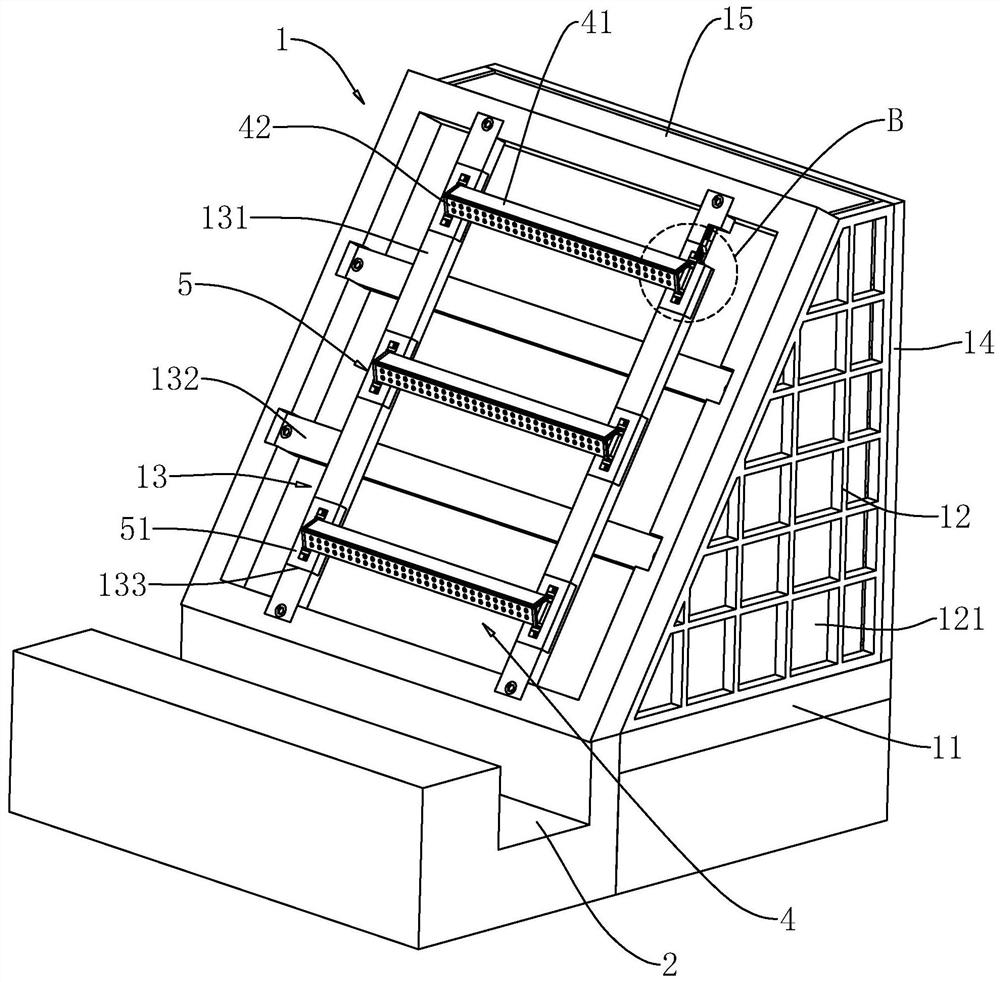

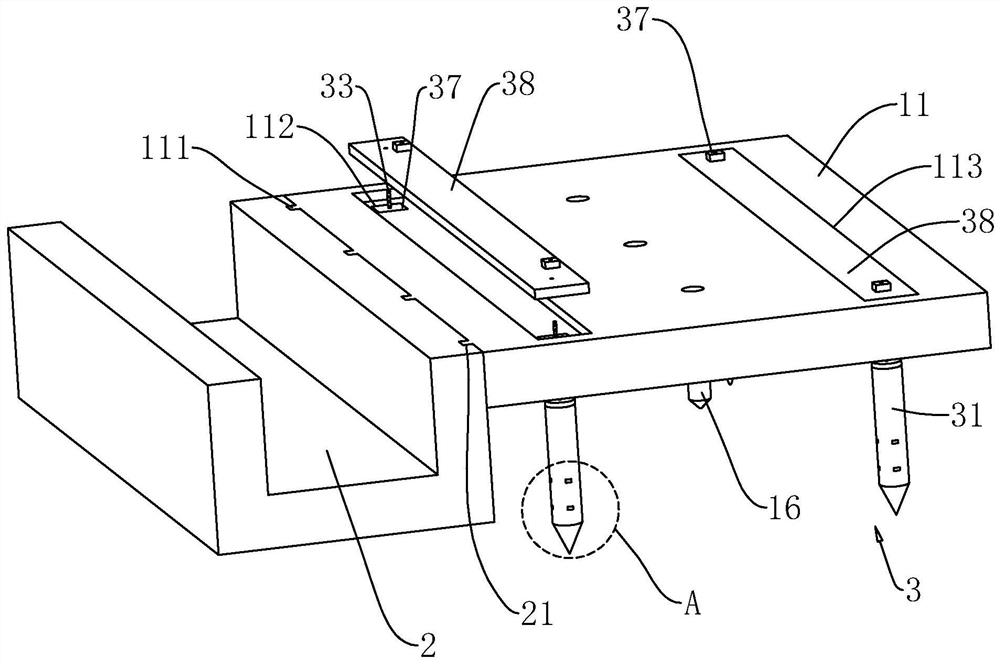

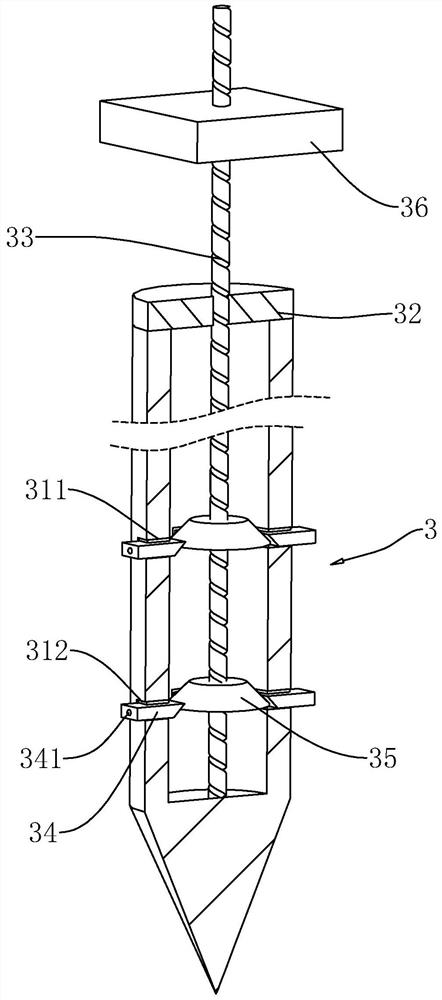

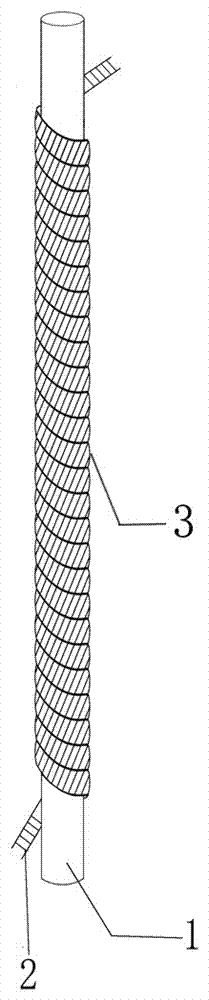

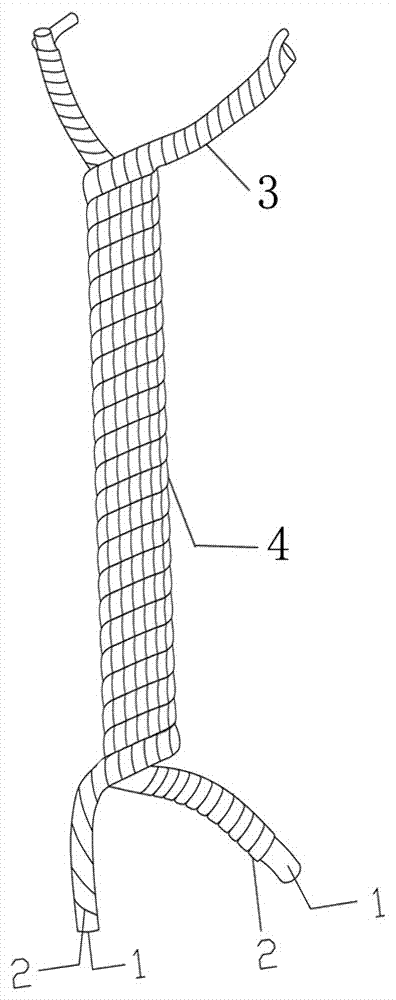

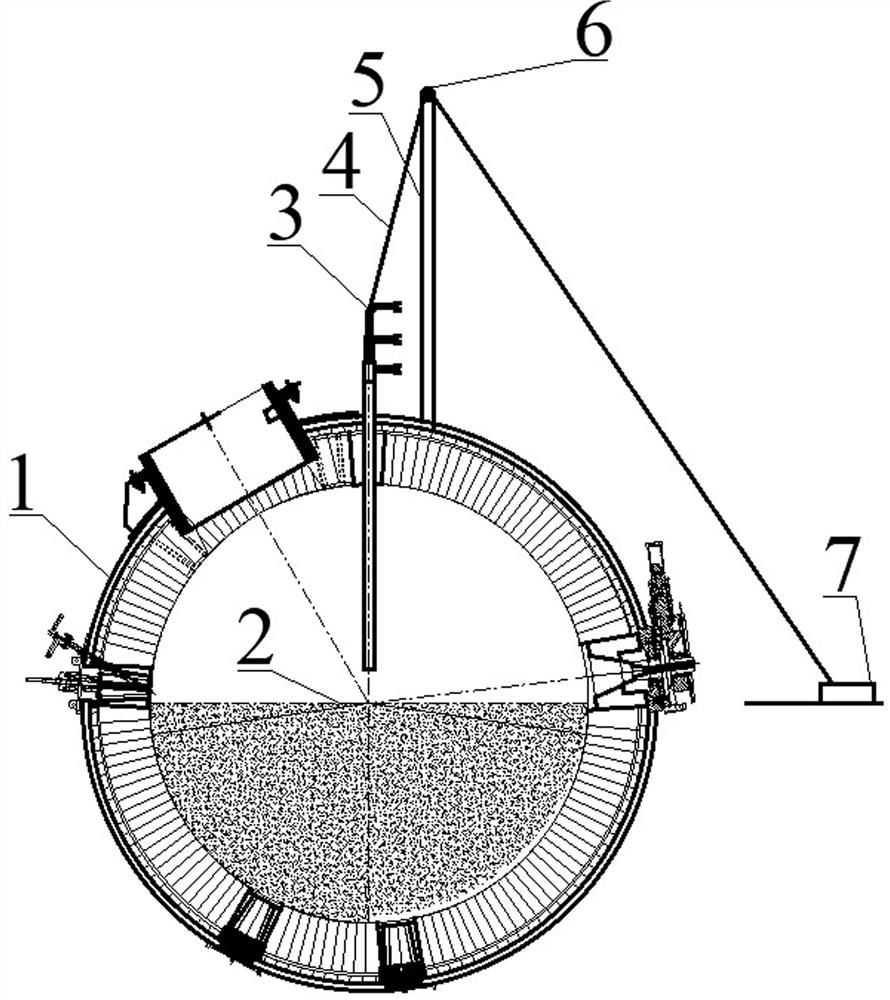

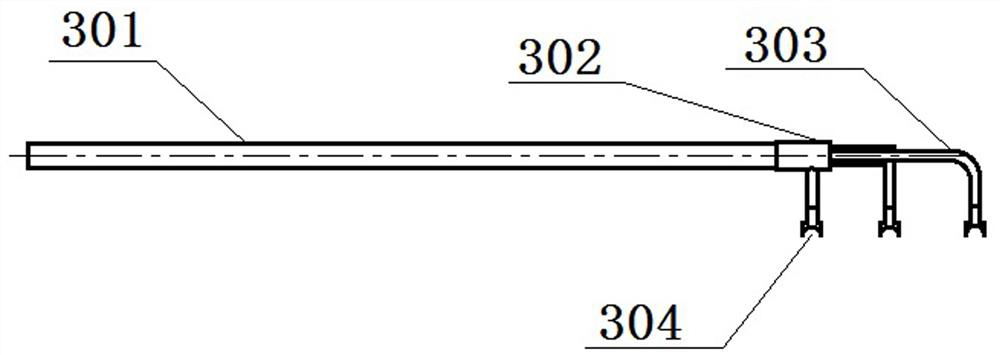

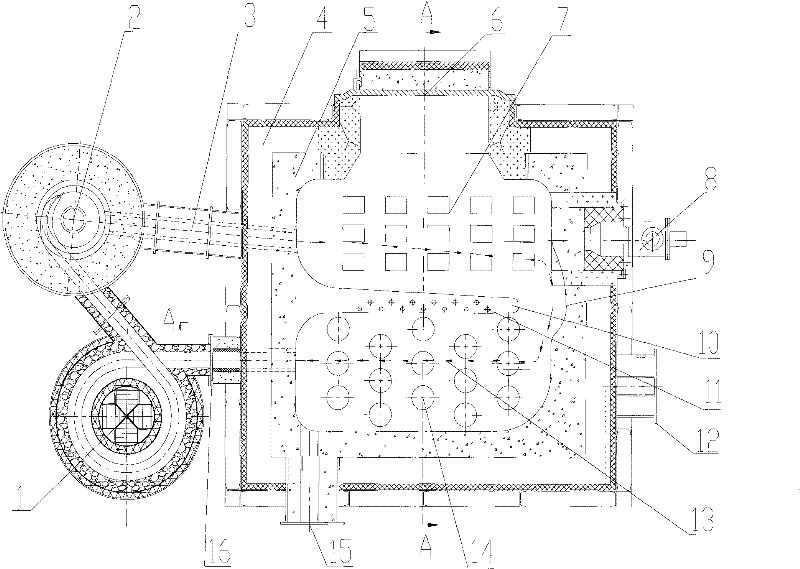

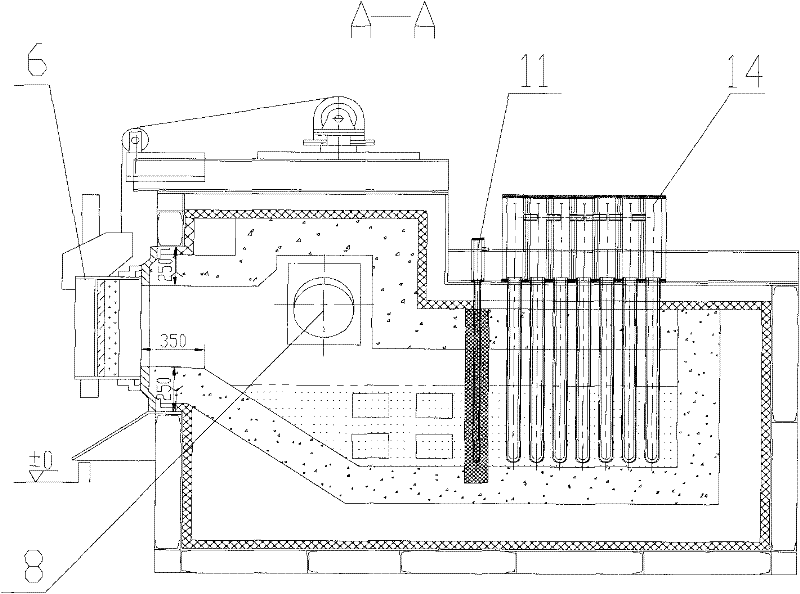

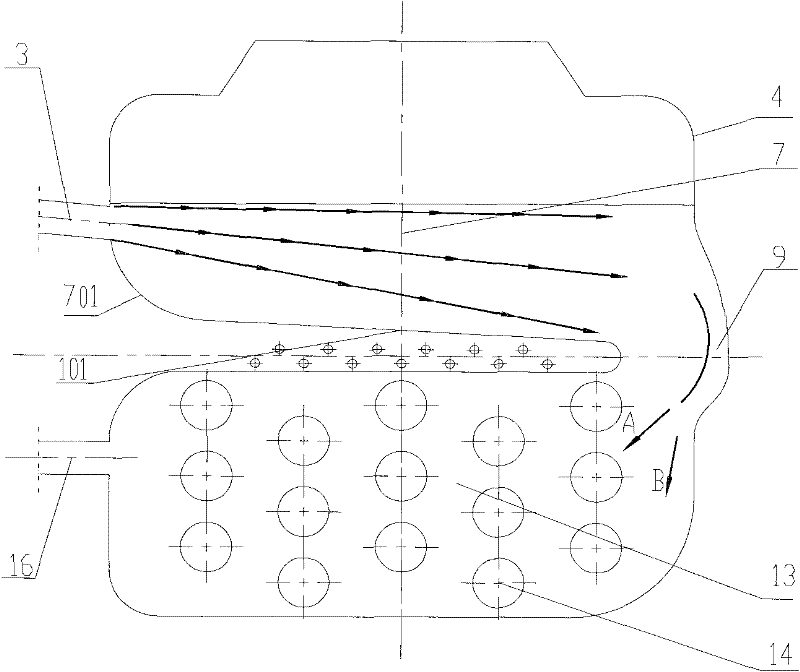

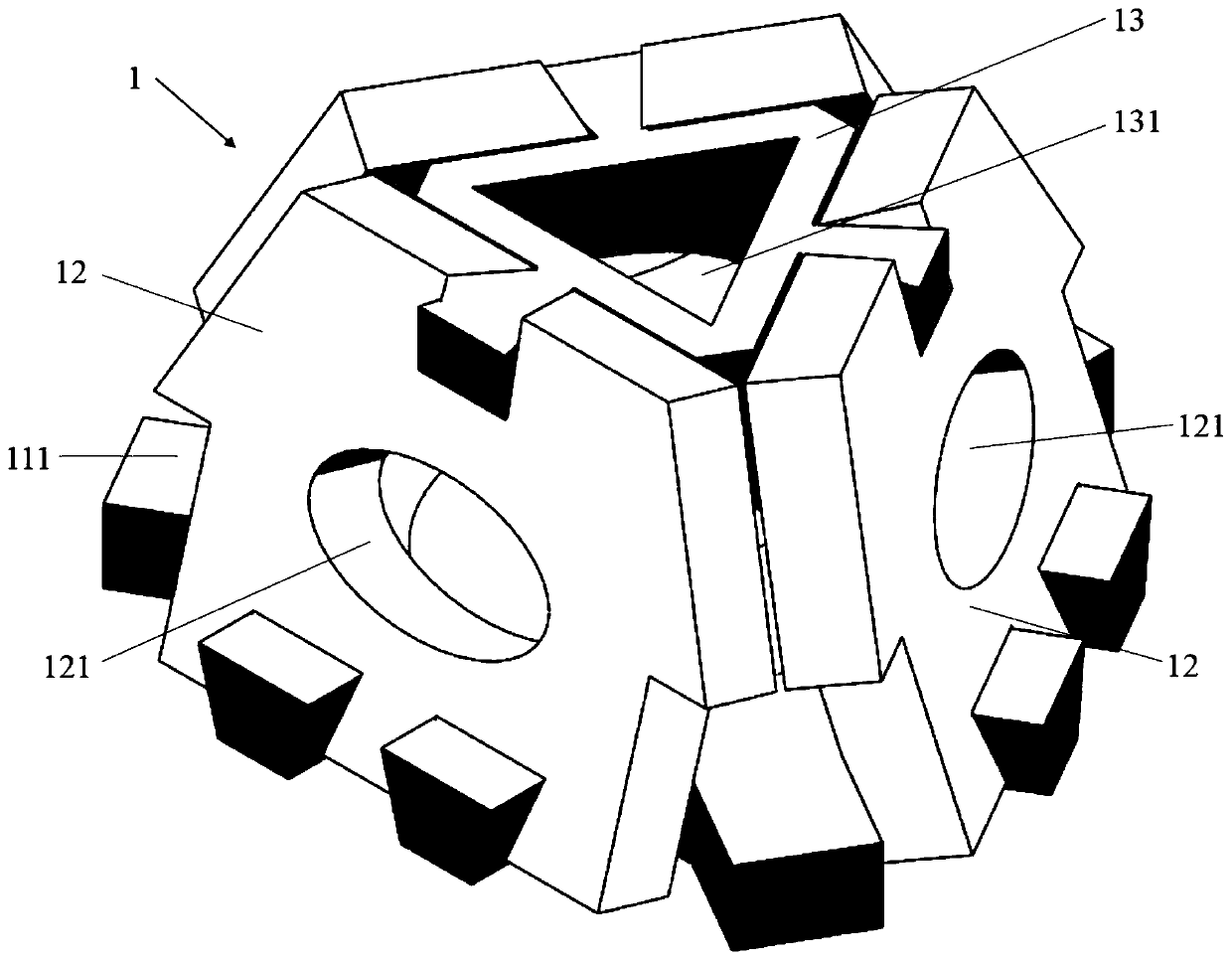

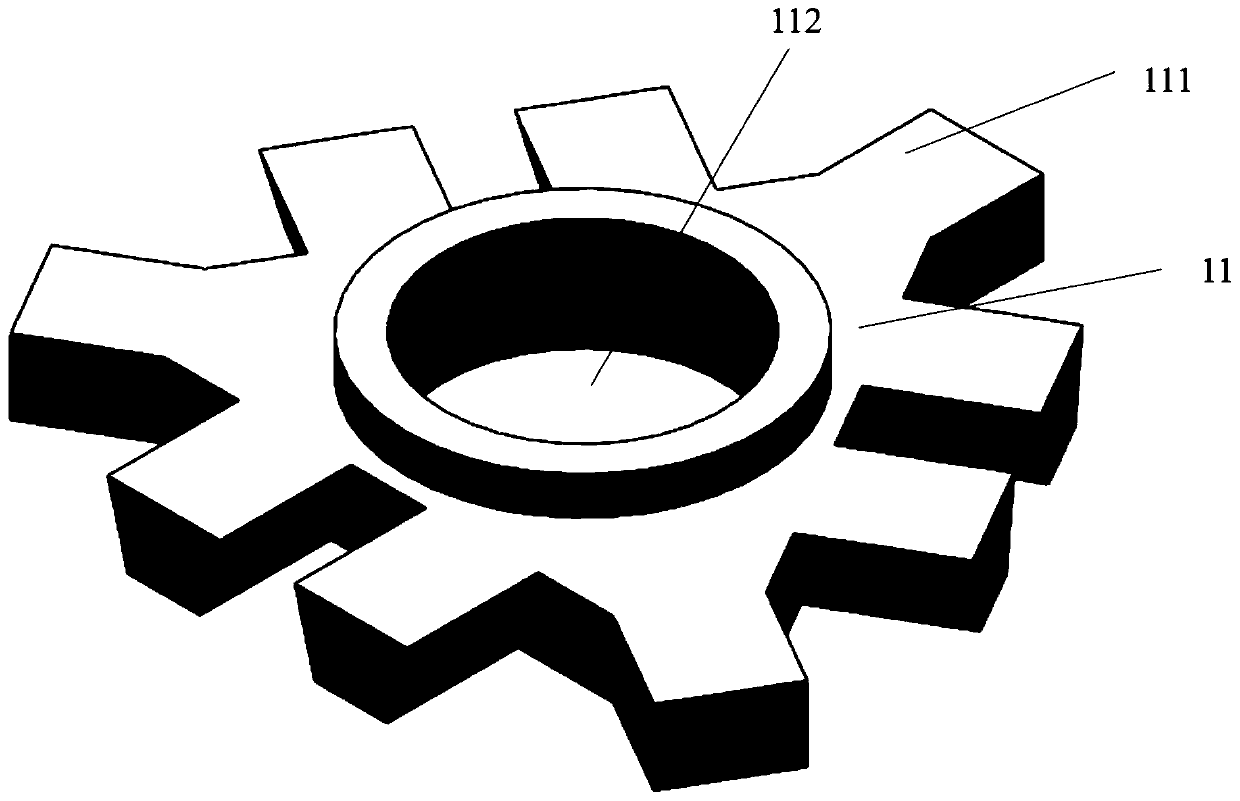

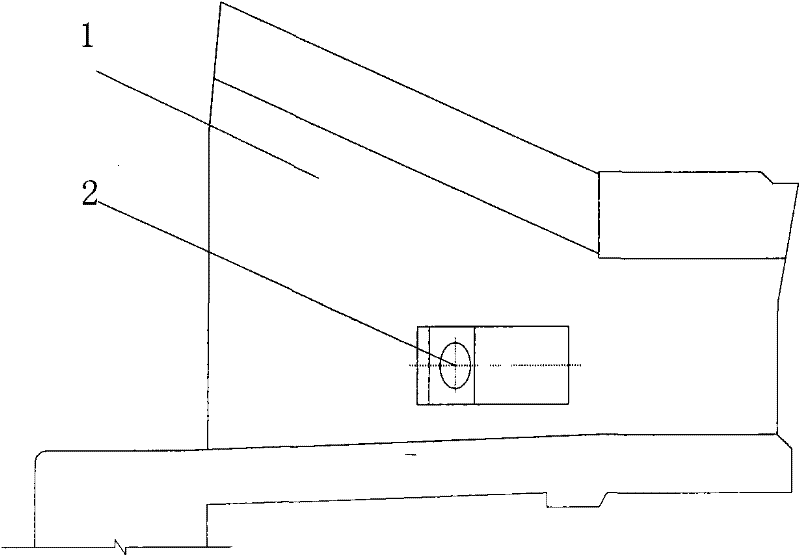

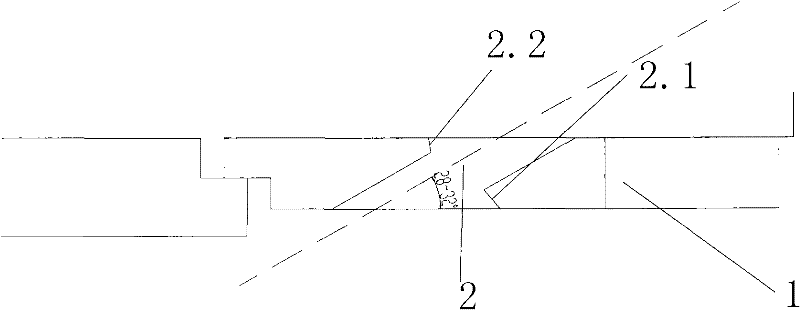

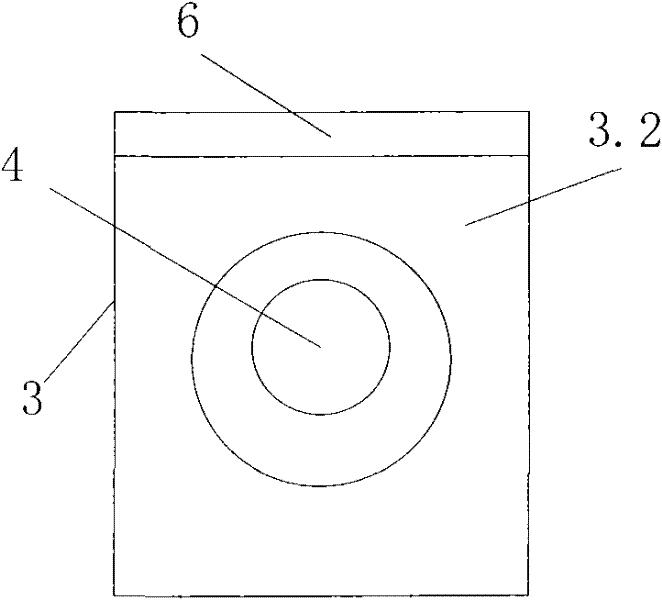

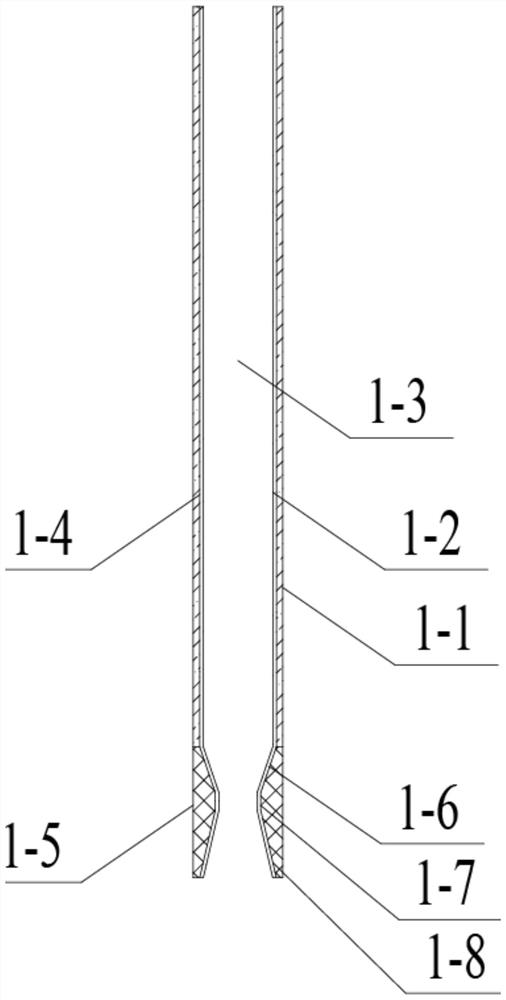

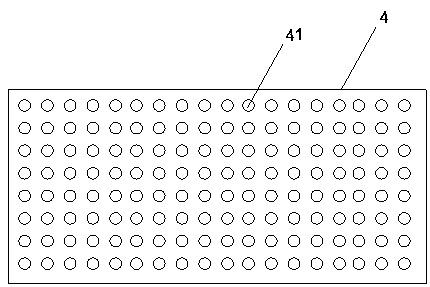

Physical model for simulating soil slope instability induced by groundwater

InactiveCN108828188AUniform penetration rateAvoid scourEarth material testingInstabilityPore water pressure

The invention discloses a physical model for simulating soil slope instability induced by groundwater and belongs to the field of physical model tests. The physical model comprises a model case and ischaracterized by further comprising an external water tank and a lifter, wherein a base is fixedly arranged on the inner bottom wall of the model case; an impervious layer is fixedly arranged on thebase; a soil layer is arranged on the impervious layer; a pore-water pressure sensor, a soil pressure sensor and a differential displacement sensor are arranged in the soil layer; an internal water tank is arranged on one side of the base; water level scales are etched on one side wall of the internal water tank; a plurality of water seeping holes are formed in the other side wall of the internalwater tank; porous stones and geotechnical cloth are sequentially arranged between the water seeping holes and the soil layer; a stainless steel hose is connected to the internal water tank; a water flow sensor is fixedly arranged on the stainless steel flexible hose. According to the physical model disclosed by the invention, underground water level height can be accurately adjusted in real time;in addition, the infiltration capacity of a slope body at certain water level height can be maintained, scouring to a soil model can be effectively avoided, and a good test effect is realized.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

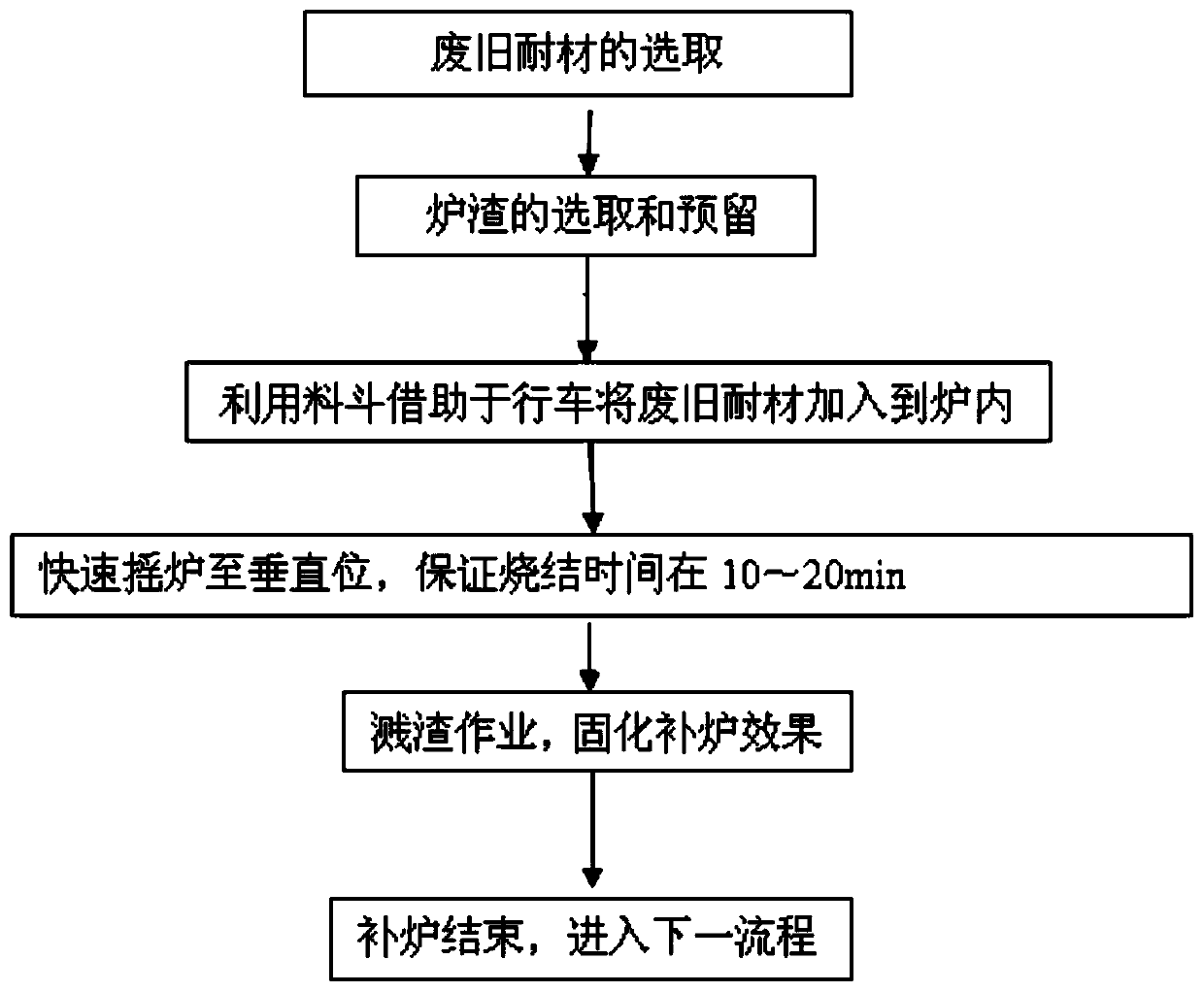

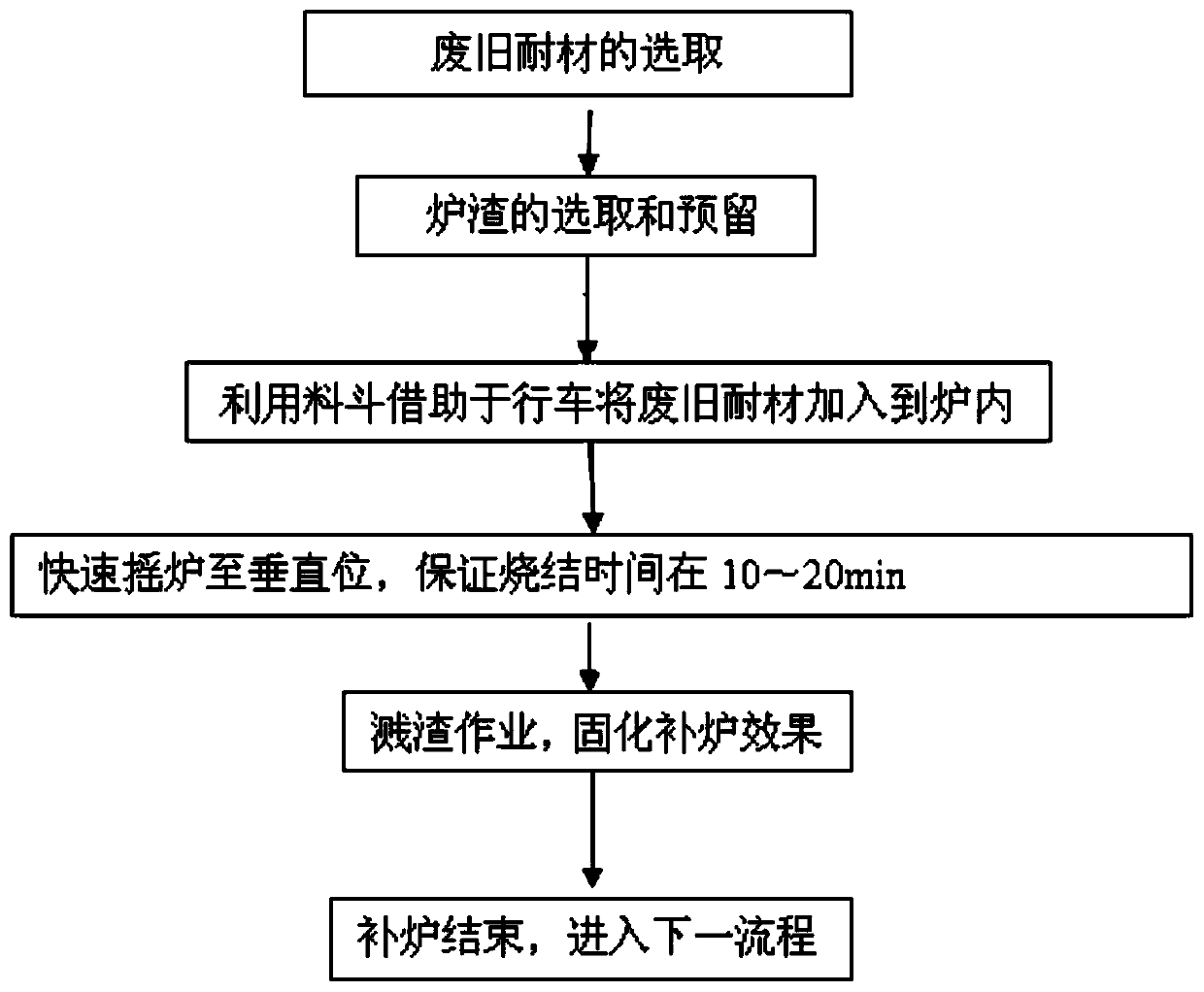

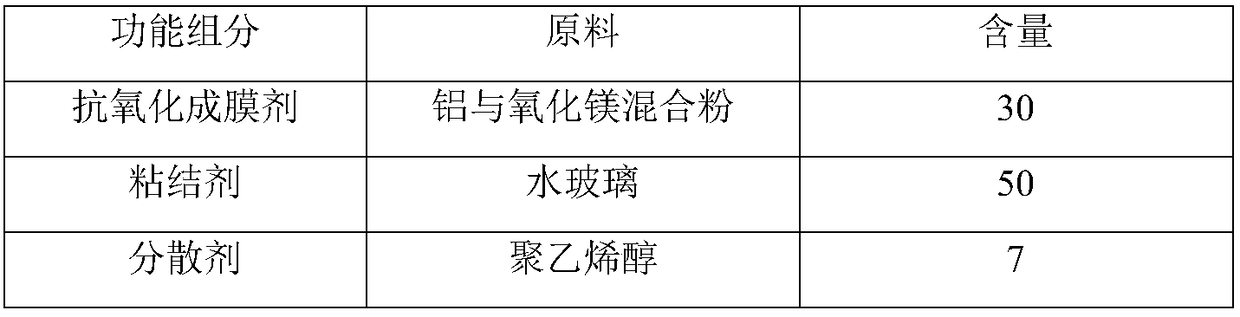

Shaping refractory material converter protection method for converter

InactiveCN110042196AExtended service lifeImprove corrosion resistanceManufacturing convertersBrickErosion rate

The invention discloses a shaping refractory material converter protection method for a converter. The method specifically comprises the following steps of: (1), selecting waste shaping refractory materials; (2), selecting slag and determining the allowance of the slag; and (3), fettling by using the shaping refractory materials. The converter protection method is simple and easy to implement; after the tapping of the converter is finished, how much of the slag to be reserved in the converter is determined according to the size of the slag and the required amount of the shaping refractory materials, the slag is quickly cooled and bonded together after a waste magnesia carbon brick or magnesite is added in, and the slag is integrated with converter lining by utilizing the temperature difference of the slag and the interface of the converter lining and through mutual diffusion among minerals, so that the fettling effect is achieved, the erosion rate of a working layer of the converter lining is slowed down, smoothness of a bottom blowing pipeline is protected, and long-acting visual operation of bottom blowing is achieved

Owner:NANJING IRON & STEEL CO LTD

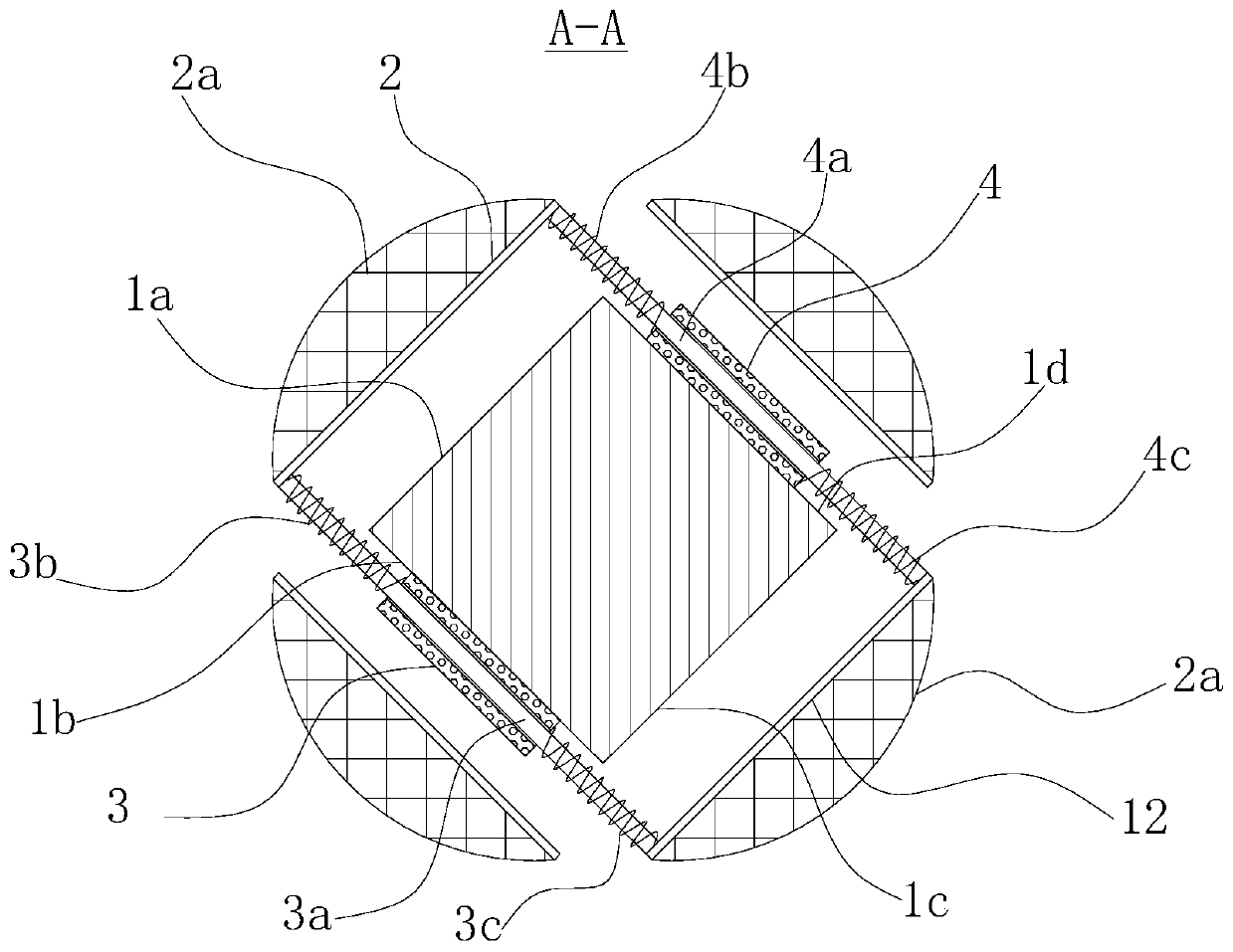

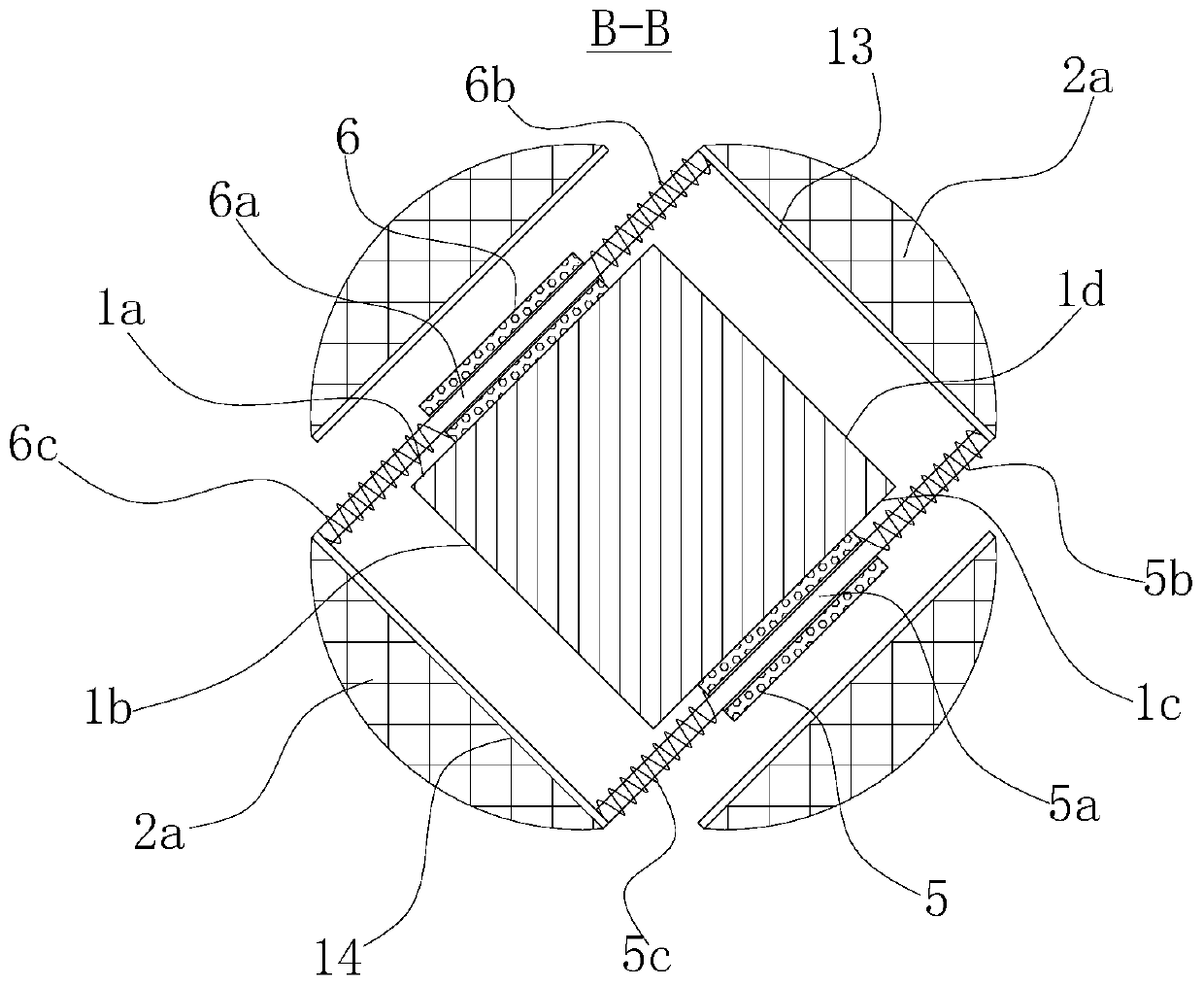

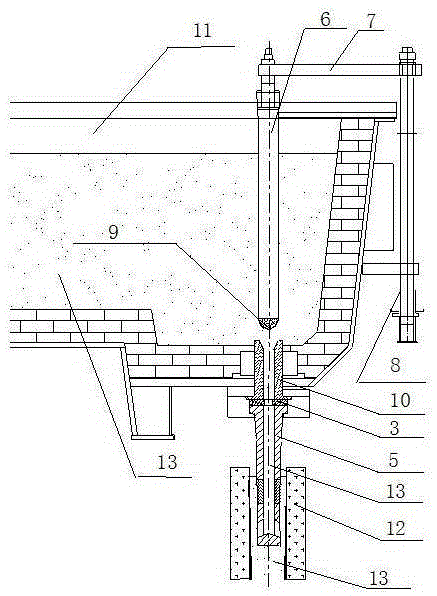

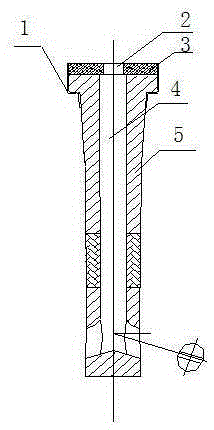

Water conservancy retaining wall structure capable of preventing water and soil loss

InactiveCN112459108AReduce scour erosionImprove protectionArtificial islandsBreakwatersMechanical engineeringRetaining wall

The invention relates to a water conservancy retaining wall structure capable of preventing water and soil loss. The water conservancy retaining wall structure comprises a retaining wall body, whereinenergy dissipation assemblies and connecting assemblies are arranged on one side of the retaining wall body; a plurality of energy dissipation assemblies are arranged at intervals in the height direction of the retaining wall body; the two connecting assemblies are are respectively arranged on both ends of the energy dissipation assemblies; the energy dissipation assemblies comprise first energydissipation plates and second energy dissipation plates which are hinged to one side of the first energy dissipation plates; the connecting assemblies comprise first sliding blocks which are hinged tothe ends of the first energy dissipation plates and second sliding blocks which are hinged to the ends of the second energy dissipation plates; connecting strips are respectively arranged on the bothends of the energy dissipation assemblies; chutes are formed in the connecting strips; the first sliding blocks and the second sliding blocks which are located on the same ends of the energy dissipation assemblies are arranged in one chute in a sliding mode; and connecting springs are respectively arranged between one groove wall of the chute and the first sliding block as well as between the other groove wall of the chute and the second sliding block. The water conservancy retaining wall structure has the effect of increasing the structural stability of a retaining wall.

Owner:安徽丰之源工程建设有限公司

Composite sewing thread of silk and yarn covering structure

The invention relates to a composite sewing thread of a silk and yarn covering structure. The sewing thread is prepared by using polytetrafluoroethylene filaments as covering yarn core wires, using yarn with performance the same as or similar to or complementary to performance of filtering material surface layer fiber as the covering yarn, forming covering yarn through a covering technology, using the covering yarn as plied yarn and then conducting cabling and plying. Due to hairness of the covering yarn, more dust escaping through needle holes can be intercepted, and meanwhile the yarn layer has certain elasticity and can more compactly block the filter bag sewing needle holes, thereby improving the dust removing efficiency of a filter bag. Due to the covering effect of yarn, polytetrafluoroethylene filaments poor in wear resistance are protected, and the sewing thread has higher wear resistance.

Owner:苏州耐德新材料科技有限公司

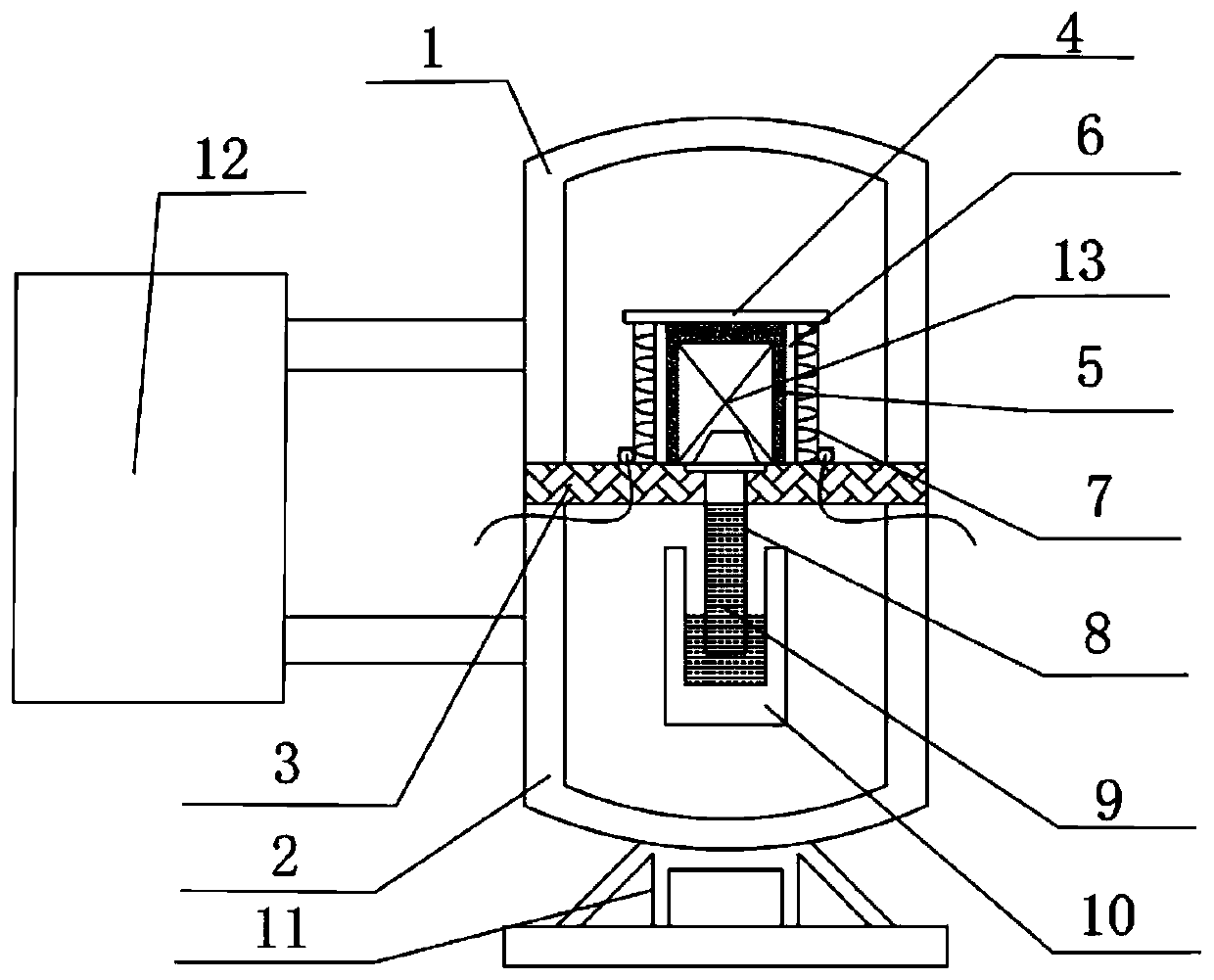

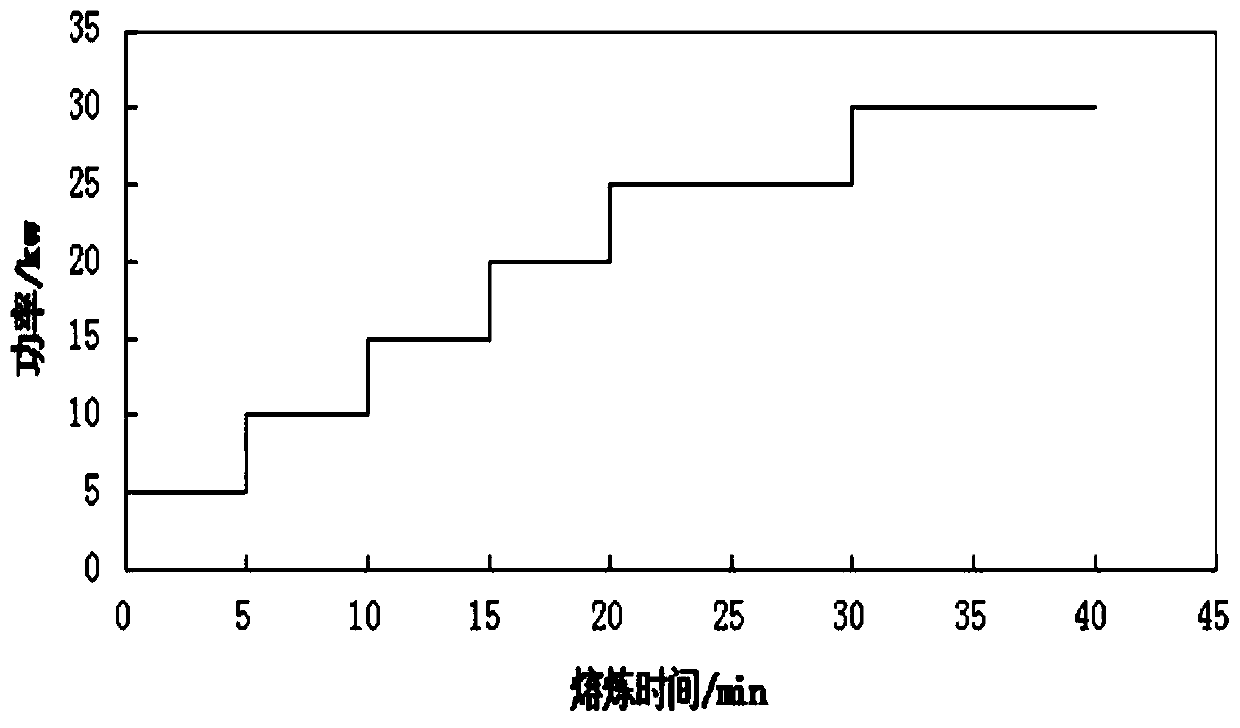

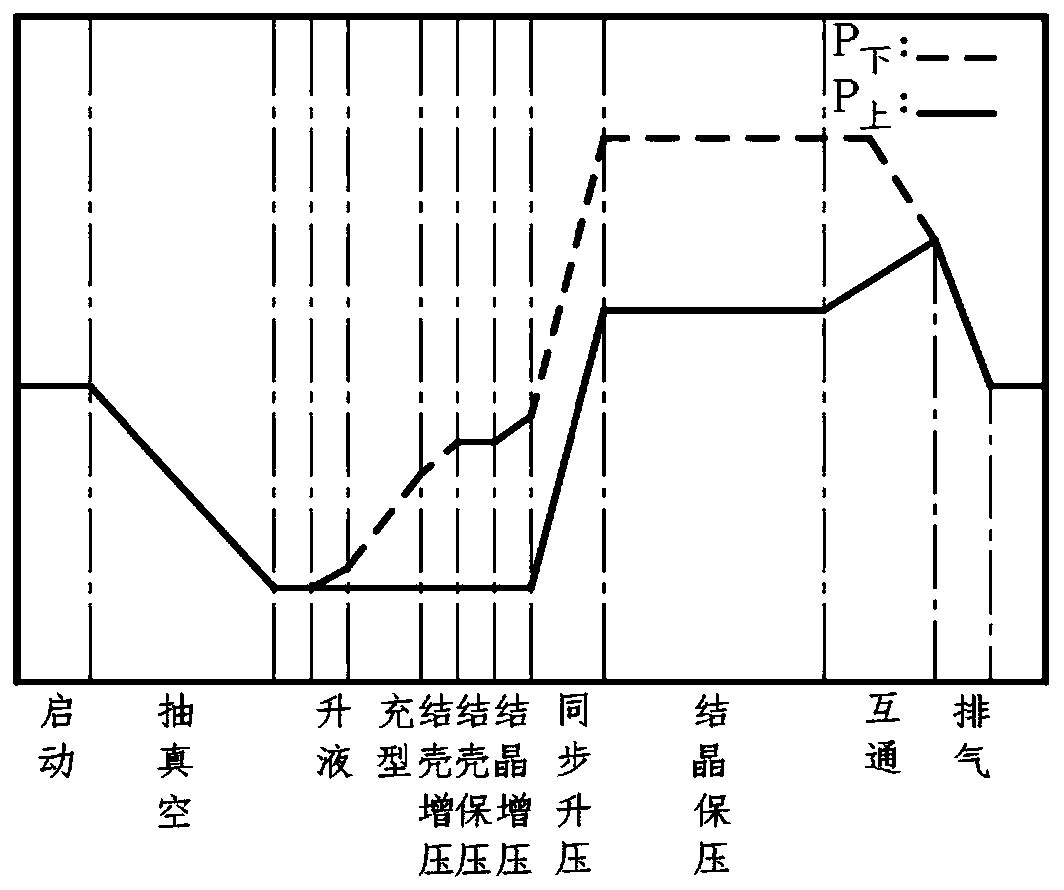

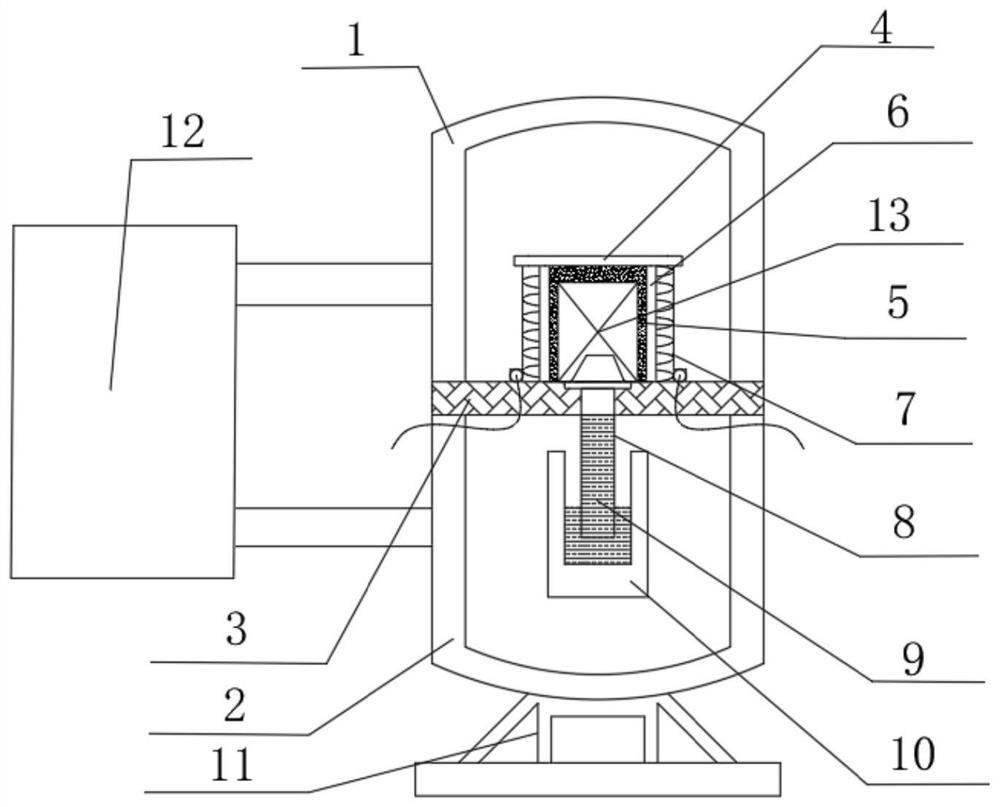

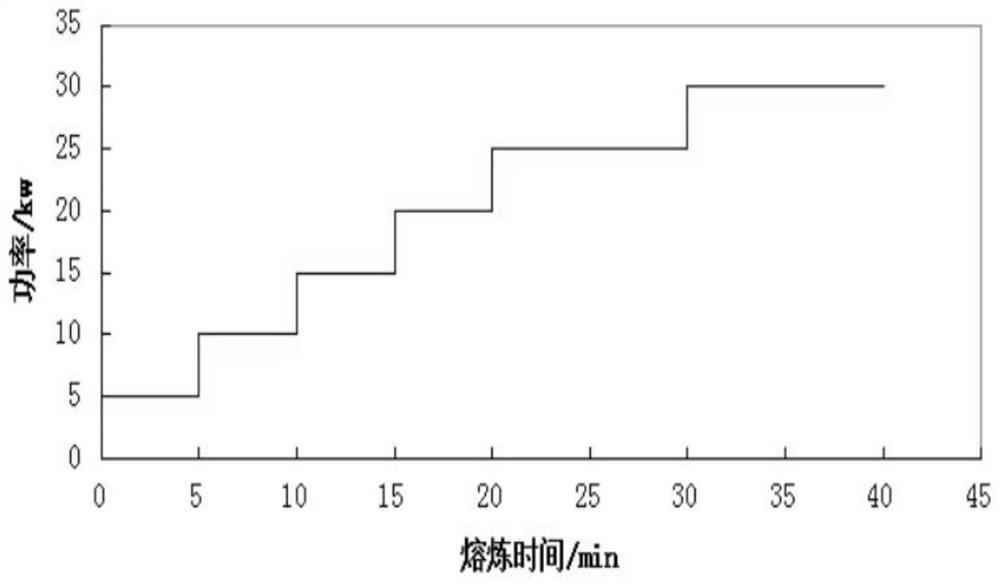

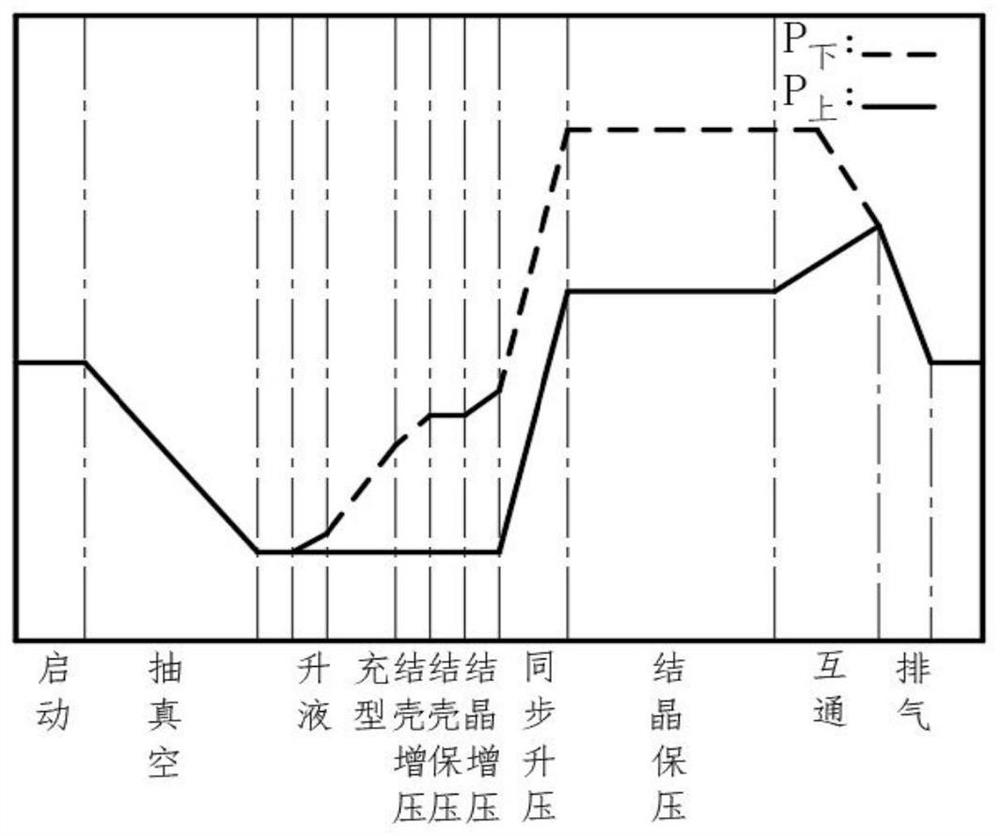

High-temperature alloy floating wall tile pressure-regulating precision casting method under action of external electromagnetic field

ActiveCN110421144AImprove metallurgical qualityReduce solidification segregationFoundry moulding apparatusWaxForced convection

The invention provides a high-temperature alloy floating wall tile pressure-regulating precision casting method under the action of an external electromagnetic field. The method comprises the following steps that printing is carried out by adopting a 3D printing technology to obtain a wax mould of a pouring system; the wax mold is atomized, polished and ground, and surface texture of the wax moldis removed; a multilayer shell is prepared on the wax mold; the shell is demolded; high-temperature alloy melt is poured into the shell by adopting vacuum counter-gravity pressure regulation to form acasting, an alternating electromagnetic field is added in the casting process of the casting, the electromagnetic volume force in the filling and solidification processes plays a stirring role on thehigh-temperature alloy melt, forced convection is generated to change the temperature field and the concentration field of the high-temperature alloy melt, and grains are refined. The high-temperature alloy floating wall tile pressure-regulating precision casting method is matched with a pressure regulating casting device, the alternating electromagnetic field is applied in the process of castingfilling and solidification, the effect of electromagnetic stirring forced convection is realized, the metallurgical quality of castings is improved, internal defects are reduced, and the density is improved.

Owner:SHANGHAI JIAO TONG UNIV

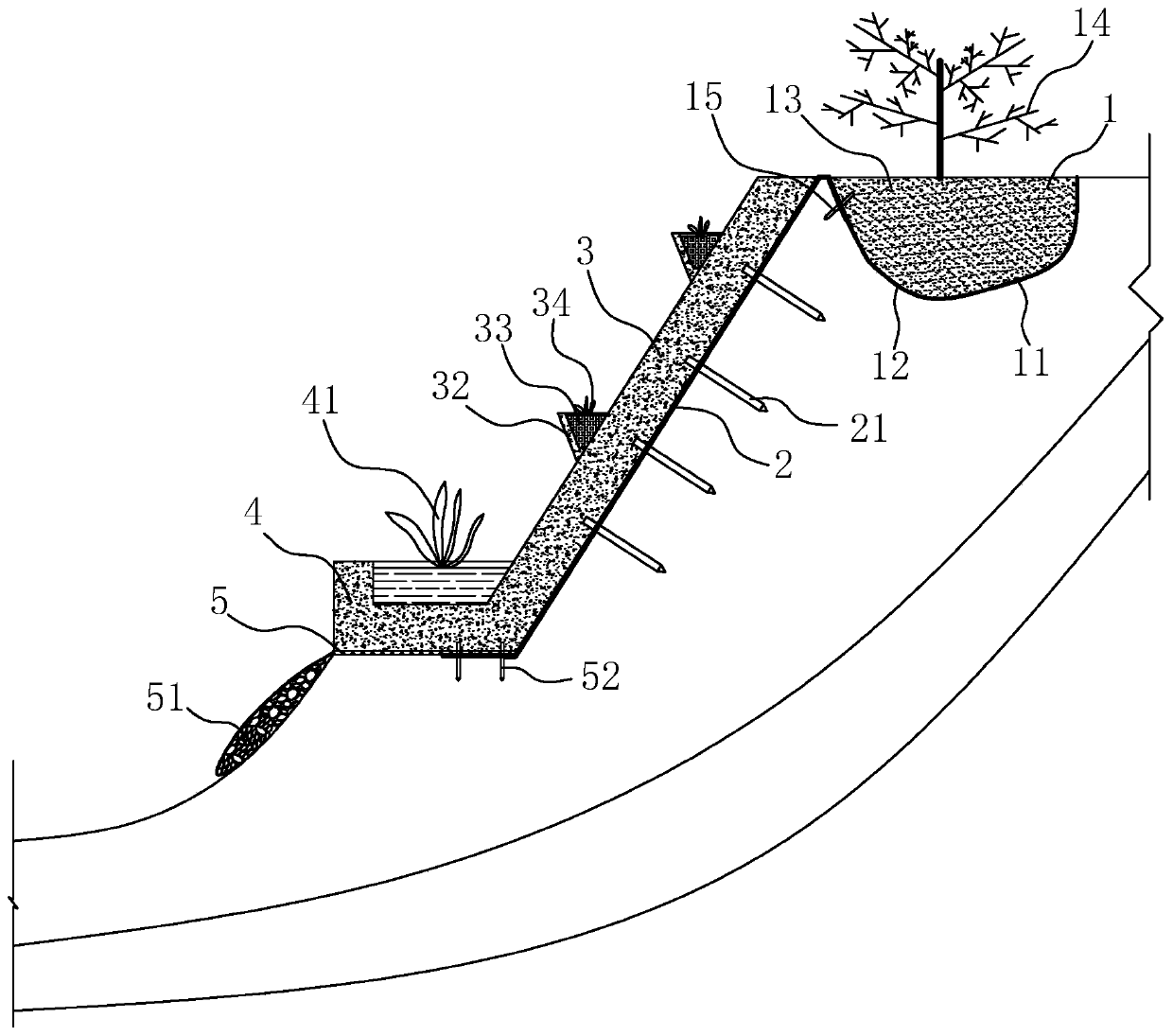

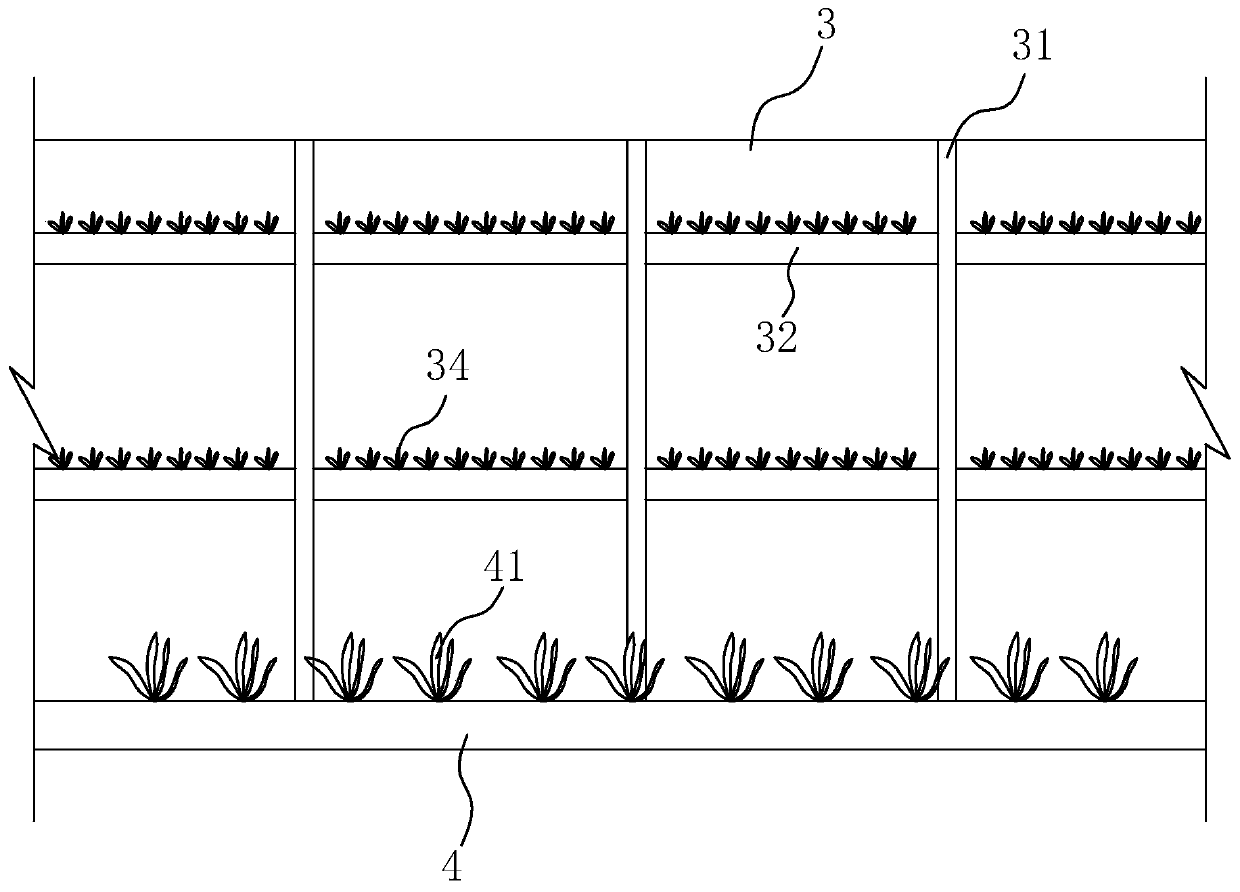

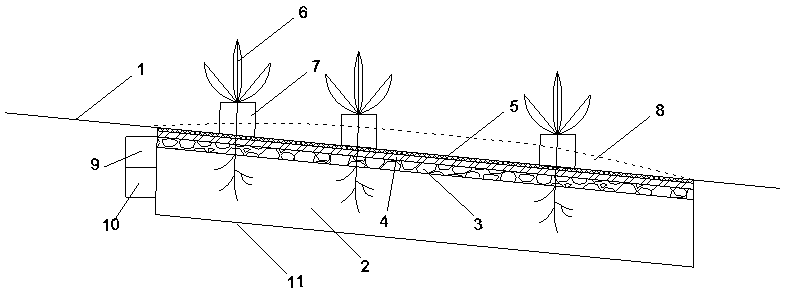

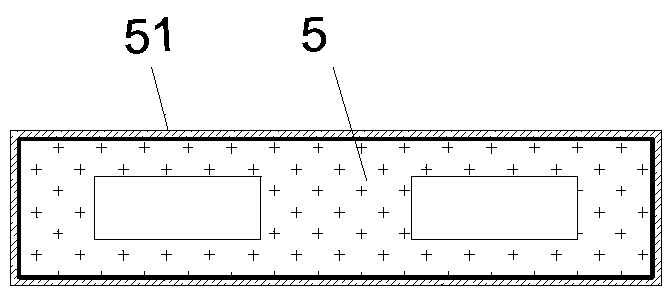

Soft rock slope ecological protection structure and construction method thereof

ActiveCN113174973AImprove liquidityImprove adhesionClimate change adaptationGrowth substratesVegetationDrainage tubes

The invention discloses a soft rock slope ecological protection structure and a construction method thereof. The soft rock slope ecological protection structure comprises an ecological protection layer and a drainage system, wherein the ecological protection layer comprises a permeable drainage layer, a soft rock matrix ecological concrete layer and a vegetation base soil layer, the permeable drainage layer is attached to the slope surface of the soft rock slope body, and the soft rock matrix ecological concrete layer and the vegetation base soil layer are sequentially arranged on the upper surface of the permeable drainage layer; and the drainage system comprises in-slope drainage pipes embedded in the soft rock slope body and a slope surface drainage structure arranged on the upper surface of the vegetation base soil layer. According to the protection structure, all the protective layers work together, multiple anti-seepage and drainage functions are achieved, the soft rock slope is stabilized together, and the construction cost is low; and meanwhile, the slope greening effect is improved, and the stability of the interior of the soft rock slope is enhanced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

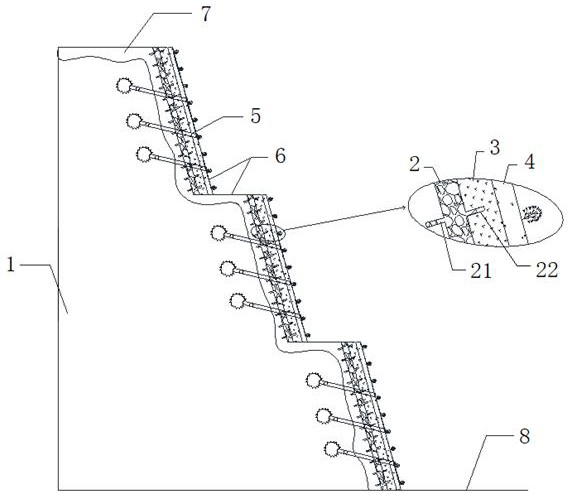

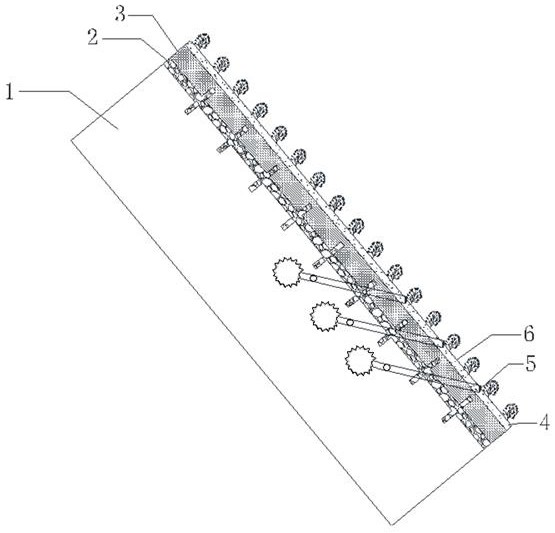

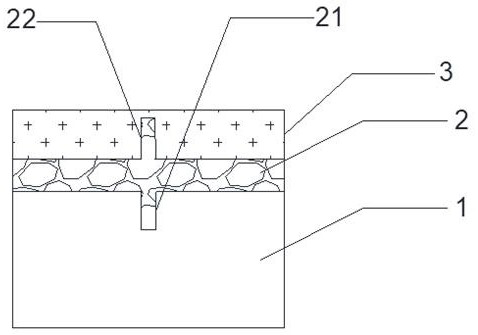

Comprehensive treatment structure for ecological protection of river channel landslide prevention slope and construction method of comprehensive treatment structure

PendingCN111472322AReduce pollutionReduce landslidesCoastlines protectionAgriculture gas emission reductionRiver routingLandslide

The invention relates to a comprehensive treatment structure for ecological protection of a river channel landslide prevention slope and a construction method of the comprehensive treatment structure.The comprehensive treatment structure for protection comprises a buffer filter belt arranged at the edge of a river channel embankment, a protective net layer laid on the river channel slope surface,a concrete protective wall poured on the river channel slope surface, an ecological planting groove fixed to the bottom of the concrete protective wall and a reinforcing net connected to the lower portion of the ecological planting groove in a pressed mode and extending to the bottom of a riverbed, wherein a planting tunnel is formed in the river channel embankment, the buffer filter belt comprises ecological geotechnical cloth laid in the planting tunnel and a planting soil layer, the protective net layer is in lap joint with the ecological geotechnical cloth, and an anchoring rod is anchored on the river channel slope surface; aquatic purification plants are planted in the ecological planting groove; and reinforcing stone blocks are loaded in the reinforcing net to form a reinforcing layer. Through the treatment structure, comprehensive protection of the river channel embankment is achieved, and the phenomena of landslide and water and soil loss are reduced.

Owner:苏州市相城生态建设管理有限公司

Method of prolonging service life of oxygen lance of converter

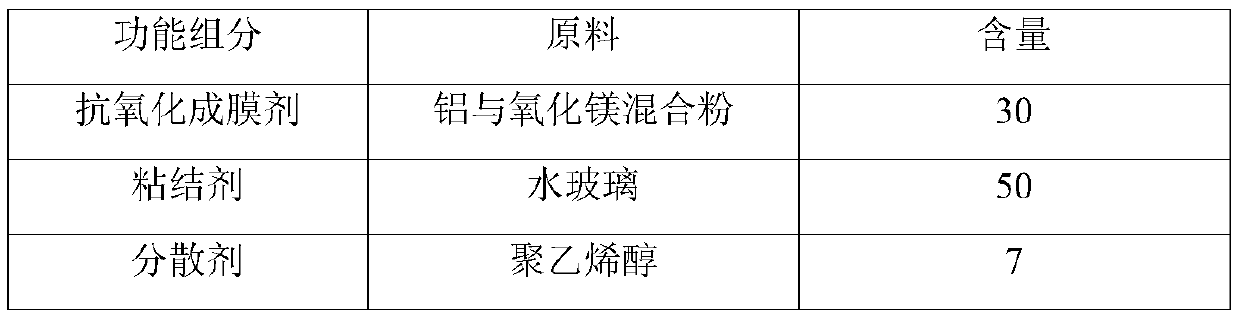

ActiveCN108642233AHigh temperature resistantImprove adhesionManufacturing convertersSlagBoron nitride

The invention relates to a method of prolonging the service life of an oxygen lance of a converter. The method comprises the following steps: carrying out treatment on bottom end surface of a spray head of the oxygen lance and treatment on side wall of an oxygen lance body, coating a high-temperature-resistant antioxidant coating to the bottom end surface of the spray head of the oxygen lance, carrying out induction heating or flame heating treatment on the end surface, spraying a first layer with a coal gas type flame high pressure spray gun, and spraying a second layer with an oxygen-acetylene flame high pressure spray gun; derusting the side wall of the gun body to a range 2-10 m far from the bottom end surface by taking the bottom end surface of the spray head of the oxygen lance as the starting point, and then smearing a coating; and spraying boron nitride powder to the coating by using the oxygen-acetylene flame high pressure spray gun. The method has the advantages that the service life of the oxygen lance is prolonged, and the labor intensity of workers is alleviated to a great extent; the deslagging treatment time as slag is attached to the oxygen lance is saved, the blowing rhythm is more compact, the effective operating efficiency of the converter is increased, and the output of steel is improved.

Owner:ANGANG STEEL CO LTD

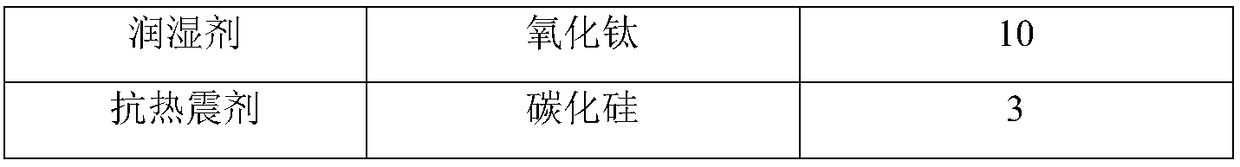

High-cleanliness spring steel and production method thereof

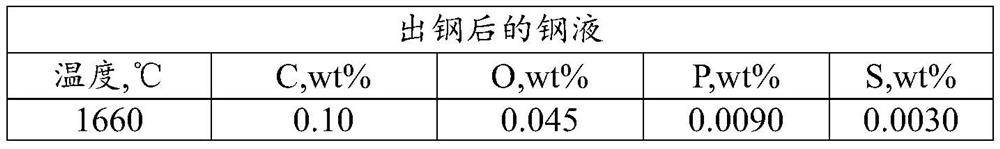

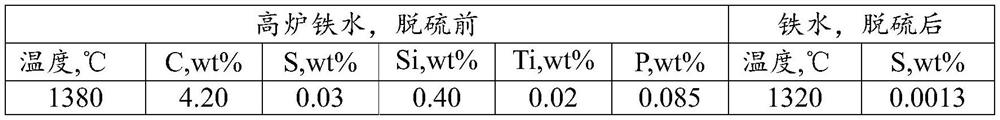

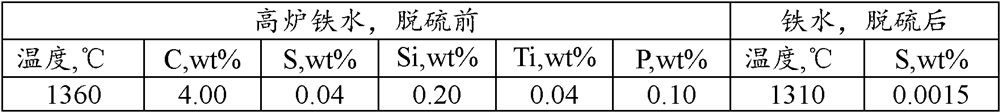

ActiveCN113061799ASmall sizeImprove purityManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses high-cleanliness spring steel and a production method thereof. The production method comprises the following steps: pretreatment: desulfurizing molten iron until the content of S in the molten iron is less than or equal to 0.0015%; mixing the molten iron and waste steel into molten steel, carrying out desiliconization, dephosphorization and oxygen blowing decarburization, obtaining the molten steel with the temperature of 111011110 DEG C, the C content of 0.1010.15%, the O content of smaller than or equal to 0.045%, the P content of smaller than or equal to 0.011% and the S content of 0.00110.008%, carrying out slag stopping tapping, carrying out deoxidation alloying, and the flow of argon blowing at the bottom of a steel ladle during tapping and the flow of argon blowing at the bottom of the steel ladle after tapping are 80011000 NL / min and 1001200 NL / min respectively; refining the molten steel to adjust chemical components and inclusions, and the flow rates of the argon blowing at the bottom of the steel ladle are respectively 1001500 NL / min, 2001100 NL / min and 501100 NL / min in other time when slag charge adding and alloying treatment are carried out and the temperature is increased by electrifying; then carrying out vacuum refining and vacuum breaking soft stirring in sequence, and the flow of the argon blowing at the bottom of the steel ladle is 20150 NL / min and 501100 NL / min; and casting into a steel billet. In the high-cleanliness spring steel prepared through the production method, the density of inclusions with the size larger than 5 micrometers is smaller than or equal to 0.5pcs / mm < 2 >, the length-width product of the maximum inclusions is smaller than or equal to 900 micrometers < 2 >, and the high-cleanliness spring steel has high cleanliness.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

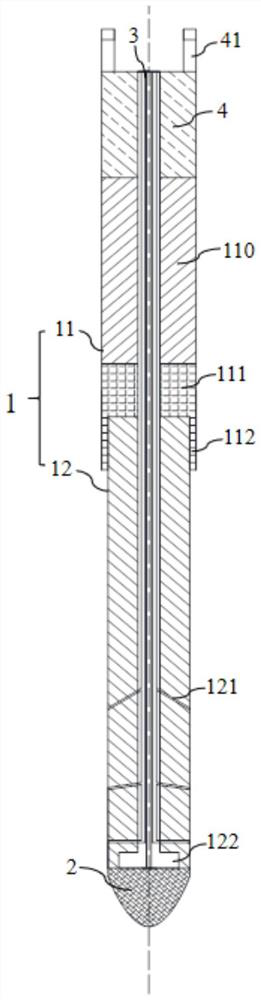

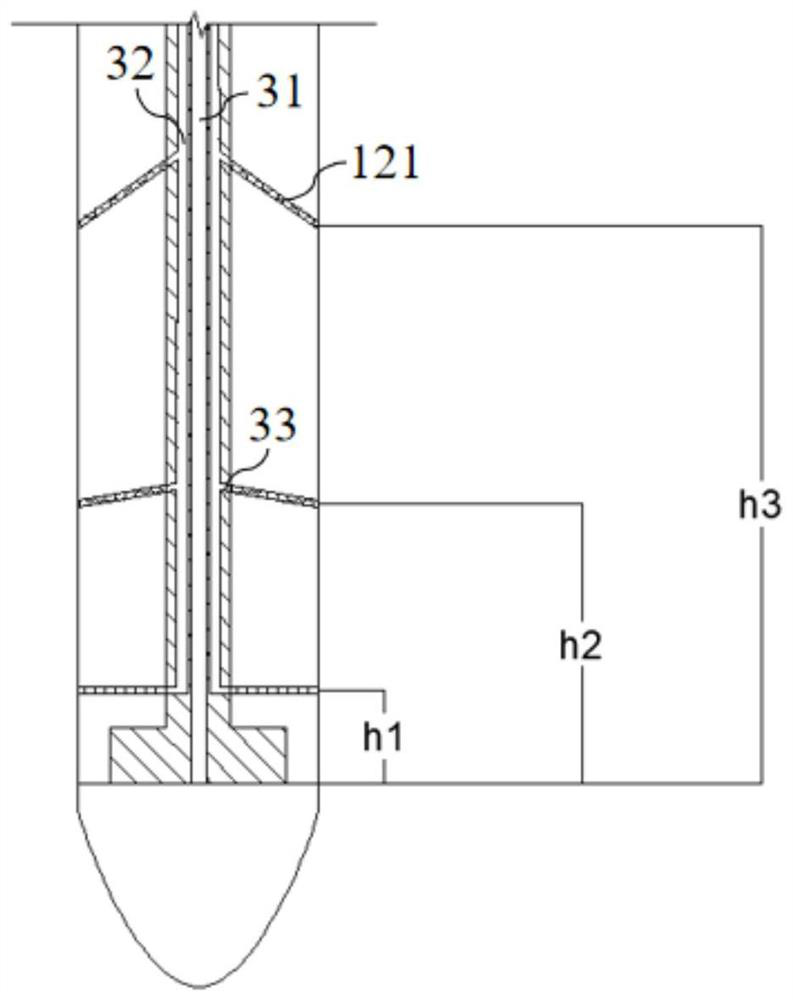

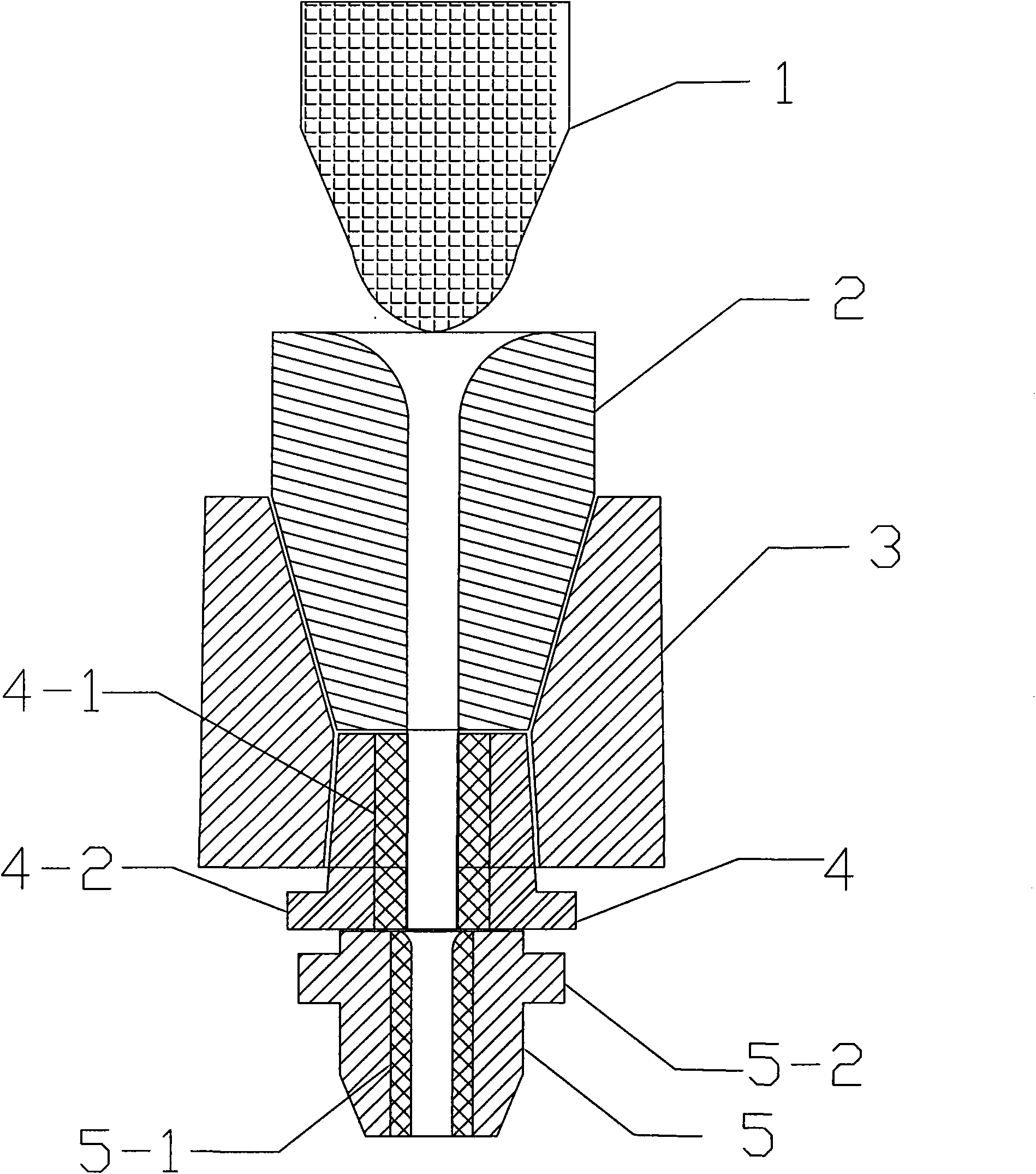

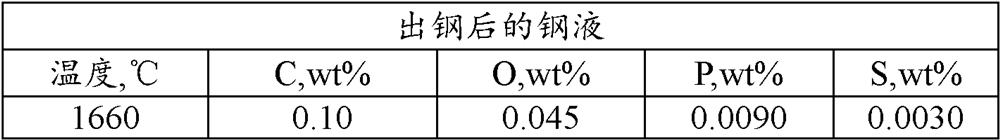

Multi-air-channel stopper rod

InactiveCN114160781ASuppress confluence vortexPrevent slagMelt-holding vesselsStructural engineeringMechanical engineering

The invention discloses a multi-air-channel stopper rod, and relates to the technical field of stopper rods. The multi-air-channel stopper rod comprises a stopper rod body and a stopper rod head, the bottom of the stopper rod body is connected with the stopper rod head, the stopper rod body comprises a stopper rod shell and a rod core, and the rod core is nested in the inner layer of the stopper rod shell; a main channel and a branch channel are arranged in the rod core, and the two ends of the main channel are connected with the argon inlet hole and the stopper rod head respectively. A side channel is arranged in the stopper rod shell, and one end of the branch channel is connected with the argon inlet hole and communicated with the side channel. According to the plug rod, the restraining effect on confluence vortexes generated at the water gap can be achieved, the space utilization rate of the plug rod is further increased by further developing the design of an existing plug rod, and argon blowing can be conducted more flexibly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

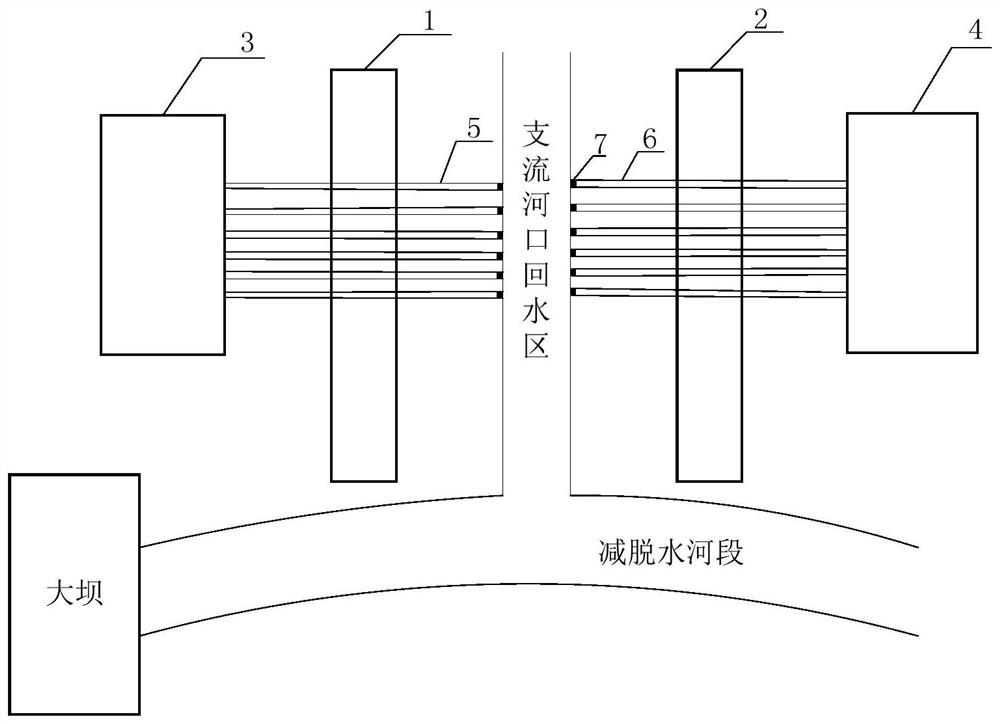

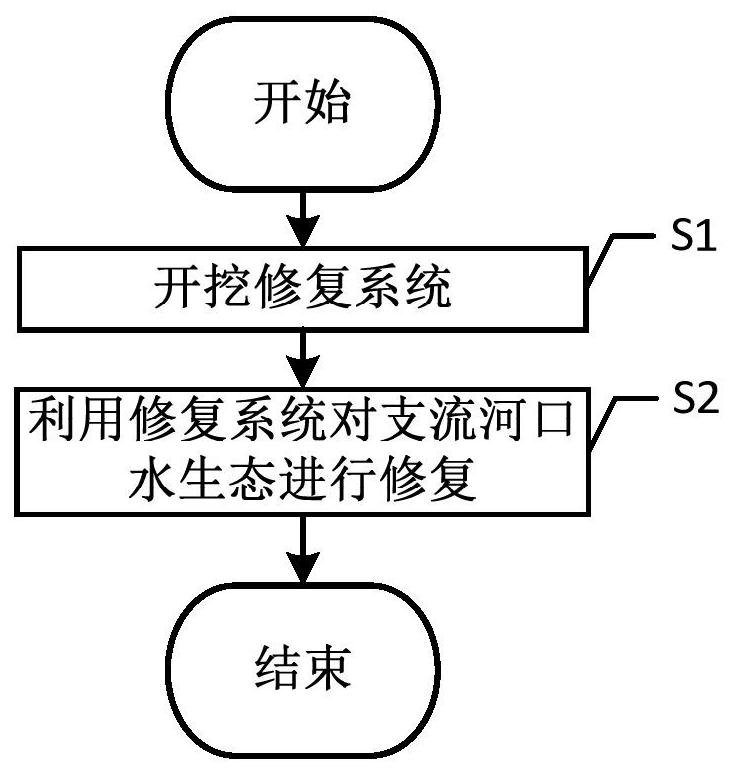

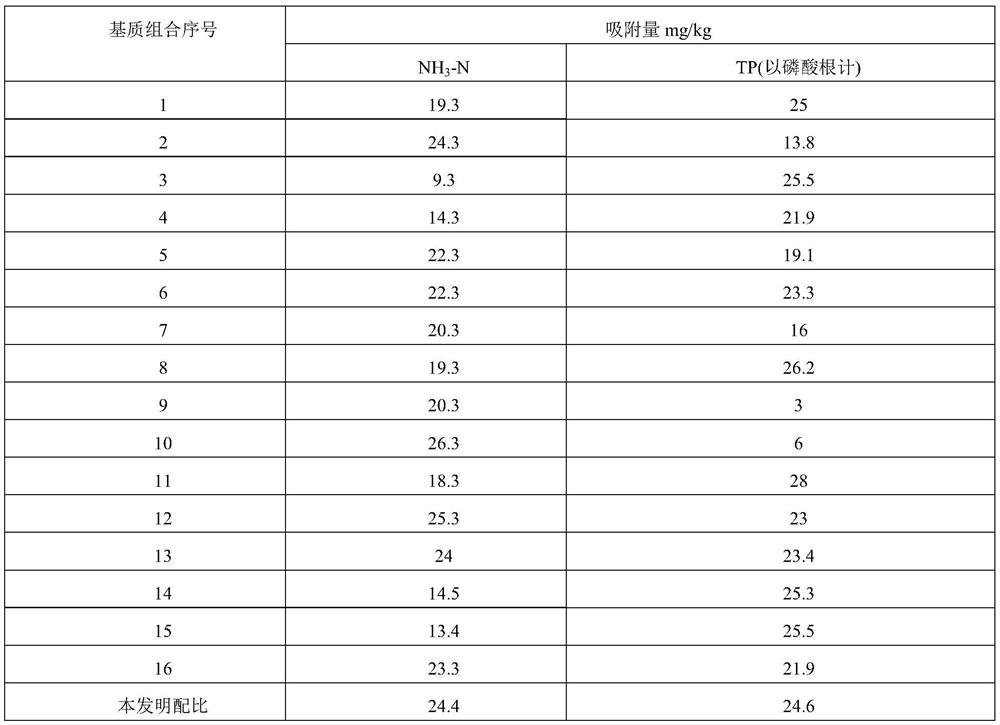

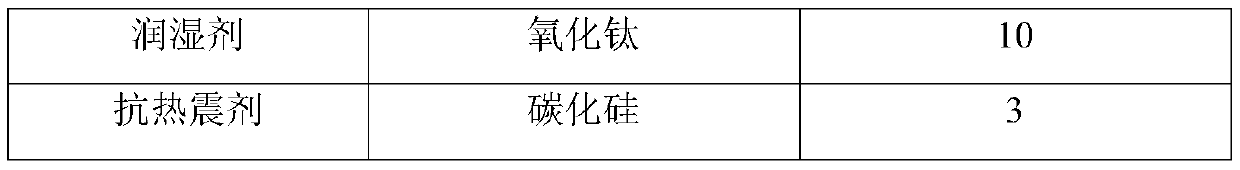

Water ecological restoration system and method for tidal tributary estuary of dam-back dehydration reach

ActiveCN111747532AReduce pollutionImprove purification efficiencyClimate change adaptationCoastlines protectionEnvironmental engineeringEstuary

The invention discloses a water ecological restoration system and method for a tidal tributary estuary of a dam-back dehydration reach. The system comprises a first bank slope type wetland, a second bank slope type wetland, a first overflow type wetland, a second overflow type wetland, a first group of wetland hydrological branches, a second group of wetland hydrological branches and gates. According to the invention, the problems that the existing wetland layout about the branch water return area mostly adopts a single wetland type when the wetland technology is used, and the function is relatively single are solved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

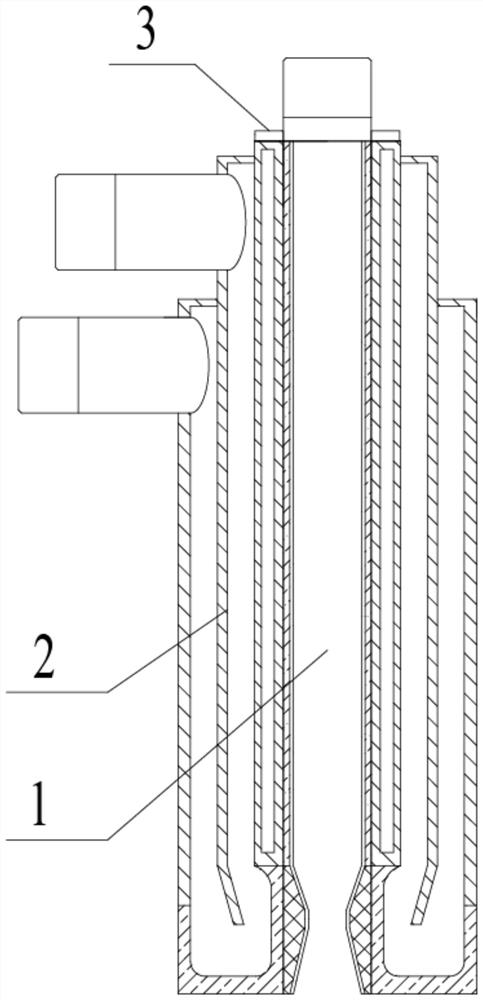

Tundish control flow method of small square billet continuous casting stopper rod and tundish water gap

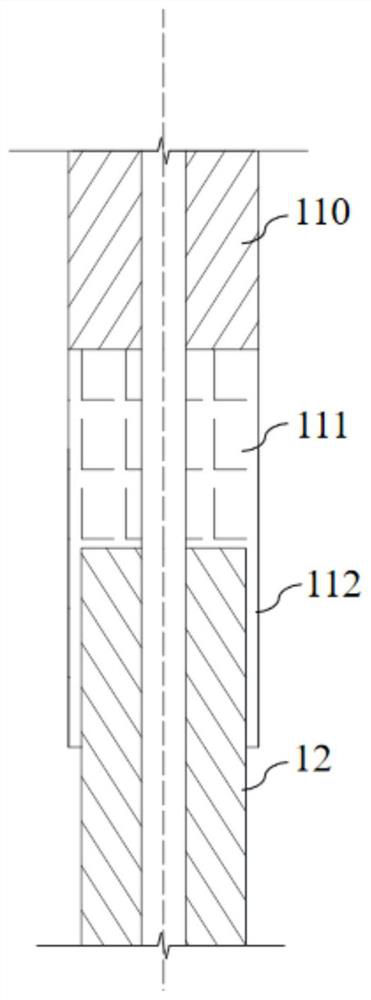

InactiveCN101564762AIncrease the area of the annular seamReduce scour erosionMelt-holding vesselsWater gapNozzle

A tundish control flow method of a small square billet continuous casting stopper rod belongs to the technical field of steel casting. An upper water gap and a middle water gap are closely abutted with each other and arranged in a tundish nozzle pocket brick from top to bottom, wherein a zirconium core is embedded into the middle water gap; a tundish water gap of a lower water gap, which is closely abutted with the middle water gap, is arranged below the tundish nozzle pocket brick, and a zirconium core is also embedded into the lower water gap; a part of the upper part of the tundish nozzle pocket brick, which is matched with the upper water gap, is in a reverse cone cylinder shape, and a part of the lower part of the tundish nozzle pocket brick, which is matched with the middle water gap, is in a cone cylinder shape with a smaller cone angle; center lines of the upper water gap, the middle water gap and the lower water gap are overlapped; the outside diameter of the zirconium core embedded into the middle water gap is larger than that of the zirconium core embedded into the lower water gap, and the inside diameter of the zirconium core embedded into the middle water gap is larger than or equal to that of the zirconium core embedded into the lower water gap; and the tundish control flow is realized by adjusting a spacing between a stopper rod arranged on the upper water gap and the upper water gap and changing the lower water gap. In the invention, integral stopper rod control flow and diameter fixing water gap control flow are organically combined, therefore, the control flow effect is good.

Owner:河南济源钢铁(集团)有限公司

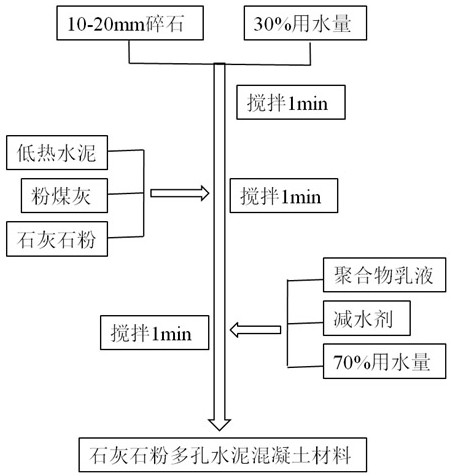

Limestone powder porous cement concrete material for dock chamber bottom plate drainage cushion layer and preparation method thereof

The invention relates to a limestone powder porous cement concrete material for a dock chamber bottom plate drainage cushion layer and a preparation method thereof. The limestone powder porous cementconcrete material is composed of low-heat cement, fly ash, limestone powder, a polymer emulsion, 10-20mm broken stone, water and a water reducing agent. The limestone powder porous cement concrete material is adopted as the dock chamber bottom plate cushion layer, and the porosity is large, the limestone powder porous cement concrete material is convenient to accumulate and discharge water broughtby ships going in and out of docks, reduces water pressure and scouring damage borne by walls and pavement structures, increases a preliminary aggregate wetting step in the limestone powder porous cement concrete material preparation process, facilitates full coating of slurry on the surface of aggregate, has good mixture working performance, and is convenient for construction and maintenance, proper limestone powder is matched with low-heat cement, so that the mechanical properties of the porous concrete are improved, the porous concrete is durable and applicable, and the limestone powder iseasily available in production, low in price and convenient to popularize and use.

Owner:HUNAN CSCEC5B CONCRETE +1

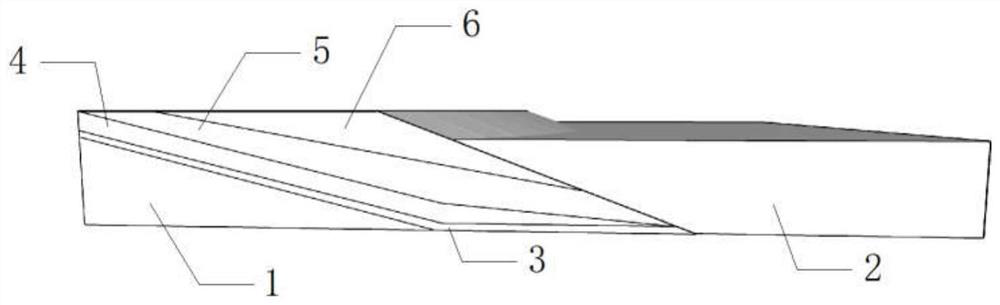

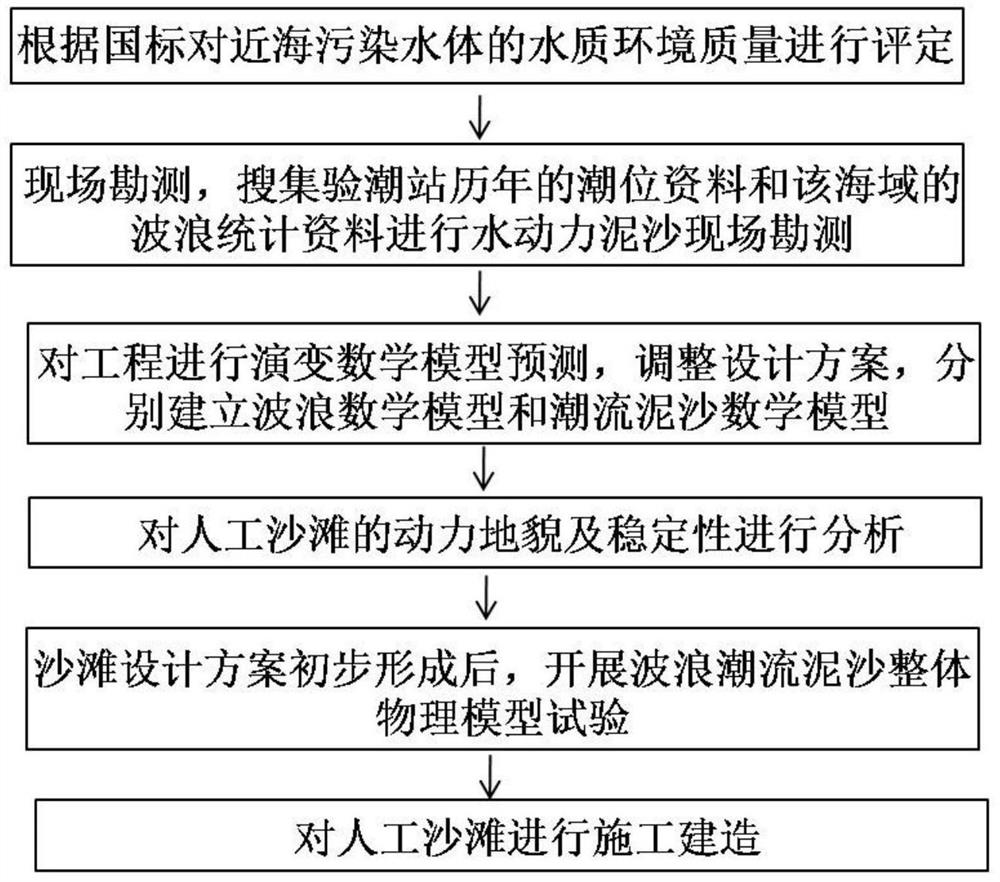

An artificial beach multi-layer structure biological water purification system and its construction method

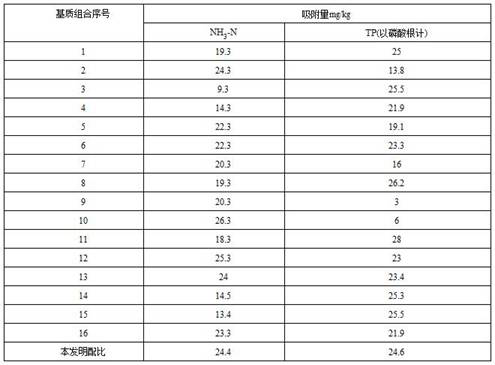

ActiveCN111003882BTo design thicknessEfficient removalTreatment involving filtrationMultistage water/sewage treatmentFiltrationBiological filter

The invention discloses a biological water quality purification system with a multi-layer structure of an artificial beach, which comprises a water-filled grid, a biological filter layer, a coarse sand layer and a fine sand layer which are successively laid on the beach surface in a natural state from bottom to top with a thickness of more than 5 cm. layer, the cross-sectional shape formed by the water-filled grid, the biological filter layer, the coarse sand layer and the fine sand layer constitutes the balanced cross-sectional shape of the beach. The invention also discloses the construction method of the system. The multi-layer filled beach of the present invention provides a space for nitrifying bacteria to survive and multiply, and can effectively remove nitrogen and phosphorus pollutants in coastal waters, so that the concentration of pollutants can be controlled within a safe range; the system can be established in any hydrological Coasts with suitable conditions are not restricted by terrain, simple in structure, and low in cost; the combination of grilles, biological filter materials, coarse sand, and fine sand can change the hydrodynamic conditions inside the beach water body, and can effectively reduce the impact of waves and tides in the open sea. The scouring and erosion of the artificial beach reduces the repair work in the later stage.

Owner:HOHAI UNIV

Furnace top blowing redox method for refining furnace

ActiveCN114369728AReduce sulfur contentShort oxidation timeCharge manipulationGas emission reductionCombustionRedox

The invention discloses a top-blowing oxidation reduction method for a refining furnace, which comprises the following steps: firstly, inserting a top-blowing spray gun into the refining furnace from a spray gun hole of a refining furnace body through a lifting device, and then connecting the top-blowing spray gun with a gas supply metal hose to complete equipment installation; when crude copper melt enters a refining furnace, a top-blowing spray gun is used for blowing oxygen for combustion supporting and heat preservation, when the crude copper melt in a furnace body of the refining furnace reaches 300 t or above, a crude copper melt sample is taken for oxygen and sulfur content analysis, needed oxidation time and gas flow are calculated, then compressed air and oxygen-enriched air are introduced into the top-blowing spray gun for oxidation, and after oxidation is finished, oxygen and sulfur in the top-blowing spray gun are removed. Natural gas is introduced through the top-blowing spray gun for top-blowing reduction, and after reduction is finished, the top-blowing spray gun is switched to be subjected to heat preservation. According to the top-blowing redox technology, the use frequency of redox mouth and furnace mouth bricks is reduced, the service life of the bricks in a vulnerable area is prolonged, efficient and long-period stable operation of the refining furnace is achieved, the frequency of overhaul and maintenance is reduced, and materials and overhaul cost are saved.

Owner:广西金川有色金属有限公司 +1

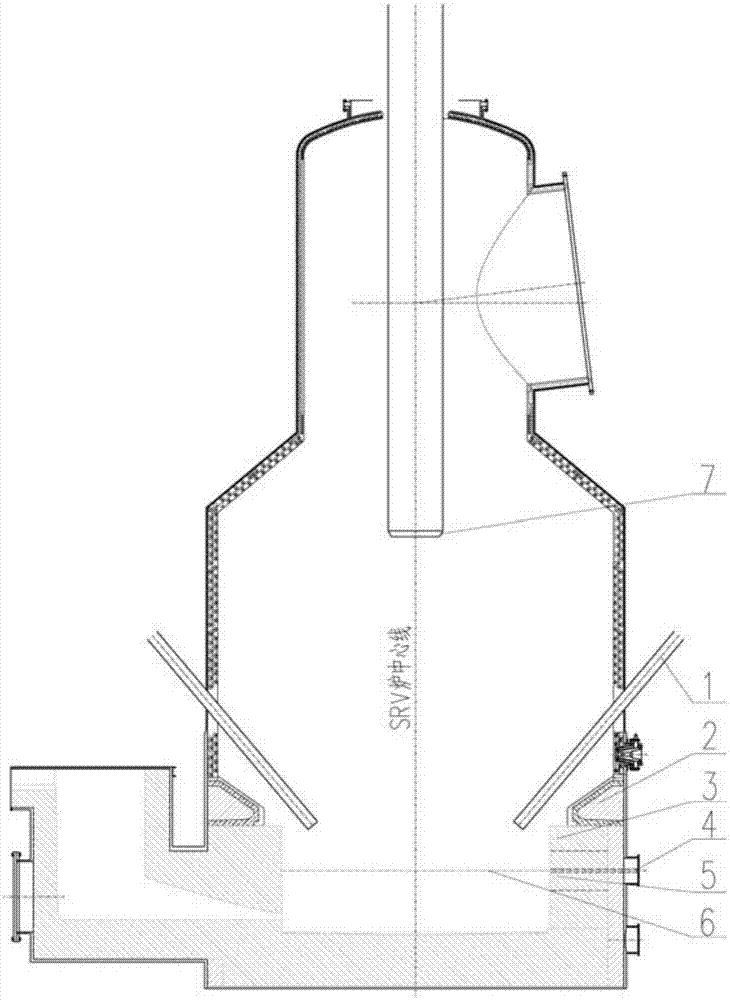

A protection method for the inner lining of the Hismelt process smelting reduction furnace

Owner:BEIJING SHOUGANG INT ENG TECH

Bridge pier stud with power generation device

PendingCN109972500AReduce scour erosionExtended service lifePiezoelectric/electrostriction/magnetostriction machinesClimate change adaptationWater flowEngineering

The invention provides a bridge pier stud with a power generation device, and belongs to the technical field of bridge equipment. The bridge pier stud comprises a pier stud, the power generation device is arranged on the outside of the pier stud, and comprises an upper fixed plate, a connecting column, a sliding rod, a lower fixed plate and a driving mechanism, the upper fixed plate is horizontally fixed on the pier stud, the lower fixed plate is horizontally fixed on the pier stud, the upper fixed plate is provided with a plurality of first perforations, the lower fixed plate is provided witha plurality of second perforations, the sliding rod is inserted into the first perforation and the corresponding second perforation, an upper limiting position plate is fixedly arranged at the upperend of the sliding rod, the lower end of the sliding rod is fixedly provided with a lower limiting plate, the upper sleeve of the sliding rod is sleeved with a pressing spring, the pressing spring ispositioned between the lower fixed plate and the lower limiting plate, a plurality of piezoelectric sheets are arranged between the sliding rod and the connecting column, and the driving mechanism candrive the sliding rod to slide up and down along the first perforations and the second perforations to cause bending deformation of the piezoelectric sheets. The bridge pier stud with the power generation device can utilize the water flow around the pier stud to achieve power generation and is green and environment-friendly.

Owner:ZHEJIANG OCEAN UNIV

A tundish composite flow control process and equipment for slab continuous casting machine

InactiveCN103273053BExtended service lifeImprove reliabilityMelt-holding vesselsSlab casterEngineering

The invention discloses a tundish composite flow control process for a slab continuous casting machine and equipment of the tundish composite flow control process. The process includes a stopper rod flow control operation stage and a submersed nozzle flow control stage, the stopper rod flow control operation stage is applied to a low casting speed state of the slab continuous casting machine, and the submersed nozzle flow control stage is applied to a normal casting speed state of the slab continuous casting machine. The equipment comprises a stopper rod and a stopper rod driving part for driving the stopper rod to move up and down. The process has the advantages that the stopper rod is used for flow control during an initial cast-on process of a tundish and an unsteady production process; after normal casting of the slab continuous casting machine, the stopper rod is lifted to a high-order position, sized casting of a submerged nozzle is adopted, and composite flow control casting is realized by cooperation of the two processes; on one hand, scouring erosion of the tundish stopper rod is reduced, and flow control reliability is improved; on the other hand, erosion scouring of a stopper rod head is reduced, accident loss caused by the fact that flow is out of control is reduced, and service life of the tundish is prolonged. The equipment has the advantages of simplicity, less investment, convenience in operation and long service life of the tundish.

Owner:JIGANG GRP

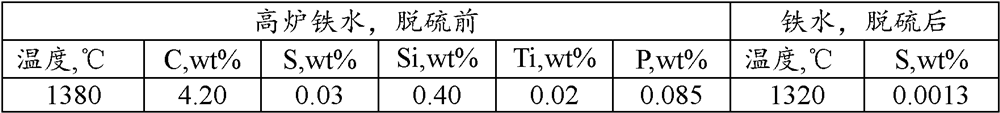

High cleanliness spring steel and production method thereof

ActiveCN113061799BSmall sizeImprove purityManufacturing convertersProcess efficiency improvementChemical compositionSlag

The invention discloses a high cleanliness spring steel and a production method thereof. The production method includes pretreatment: desulfurizing molten iron to the extent that S≤0.0015% in molten iron; mixing molten iron and scrap steel into molten steel for desiliconization, dephosphorization, oxygen blowing and decarburization, and obtaining a temperature of 1630-1660° C., C 0.10-0.35 %, O≤0.045%, P≤0.011%, S 0.003~0.008% of molten steel, slag blocking and tapping and deoxidation alloying, the flow rate of argon blowing at the bottom of the ladle during tapping and after tapping is respectively 800~ 1000NL / min, 100~200NL / min; after that, the molten steel is refined to adjust the chemical composition and inclusions, and the flow rate of argon blowing at the bottom of the ladle is 300~500NL during the addition of slag and alloying treatment, when electrifying and heating up, and during the rest of the time. / min, 200~300NL / min, 50~100NL / min; then vacuum refining and air-breaking soft stirring are carried out in sequence, and the flow rate of argon blowing at the bottom of the ladle is 20~50NL / min, 50~100NL / min respectively; billet. In the high-cleanness spring steel prepared by the production method, the density of inclusions with a size of 5 μm or more is ≤ 0.5 pieces / mm 2 , the length-width product of the largest inclusion is less than or equal to 900 μm 2 , with high cleanliness.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

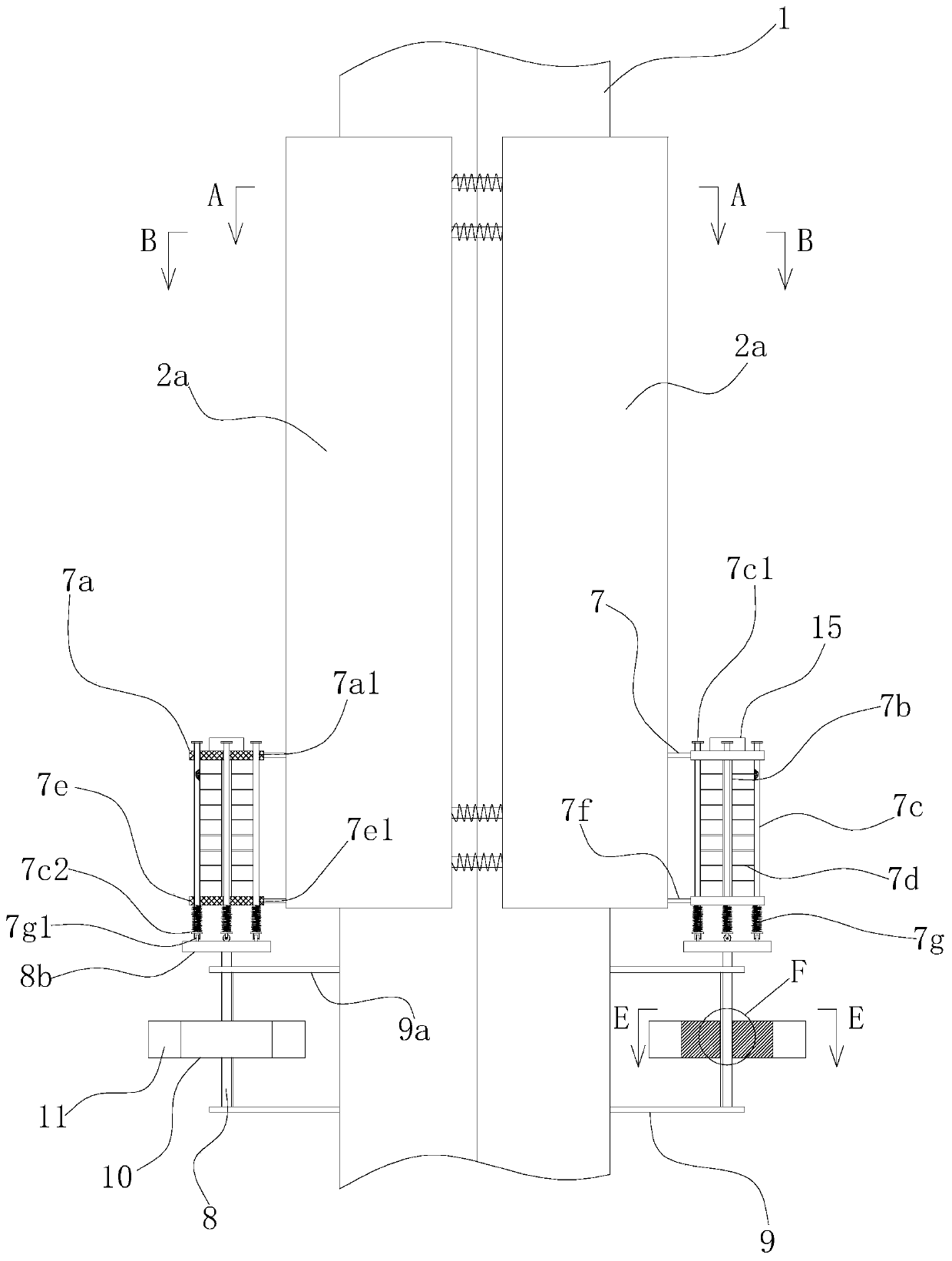

RH method vacuum tank with lifting gas pipeline and arrangement method of lifting gas pipeline thereof

Owner:MCC CAPITAL ENGINEERING & RESEARCH

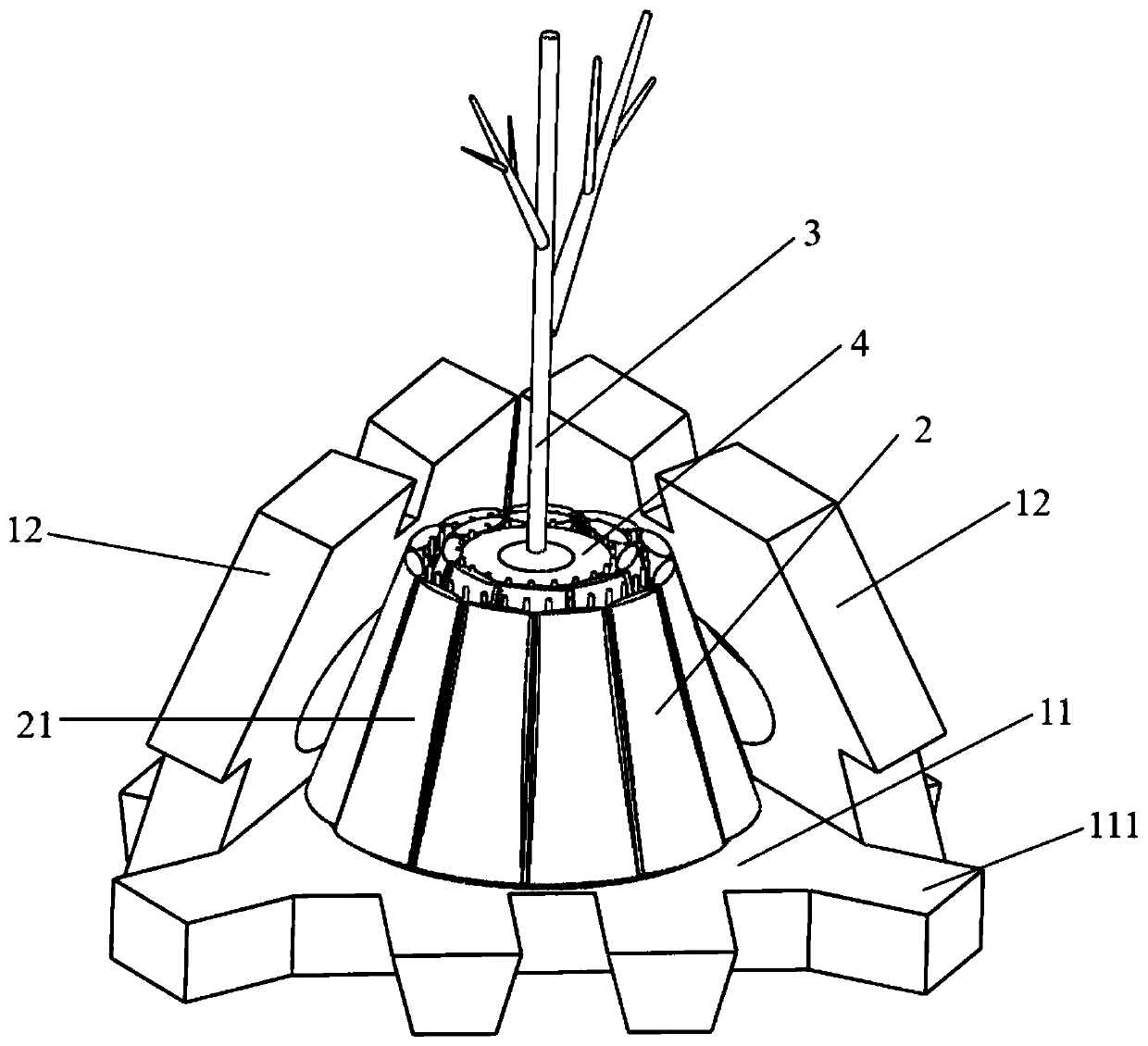

Inner structure of high-efficiency energy-saving aluminum and aluminum alloy isothermal smelting furnace

InactiveCN101852543BInto the uniformReduce lossesLighting and heating apparatusCirculating pumpErosion

The invention provides an inner structure of a high-efficiency energy-saving aluminum and aluminum alloy isothermal smelting furnace, a partition wall is arranged at the middle part of a hearth, the hearth is divided into a furnace starting melting region and a heating region through the partition wall, a feeding well and a circulating pump are arranged outside a furnace body, the inlet of the circulating pump is communicated with the hearth of the heating region, the outlet of the circulating pump is communicated with the feeding well, the feeding well is communicated with the hearth of the furnace starting melting region, the partition wall is provided with an inclined surface with an inclination angle of 3 to 20 degrees, a guiding region is arranged at one end of the partition wall, and the guiding region is arranged between the furnace starting melting region and the heating region and is in the shape of a spindle-shaped small-curvature arc. When in working, an aluminum liquid in the furnace starting melting region passes through the guiding region and enters the heating region in a more advantageous flowing state. The inner structure of the aluminum and aluminum alloy isothermal smelting furnace enhances the heat exchange between the aluminum liquid and a heater, reduces the scouring erosion of the aluminum liquid to a wall surface and enables the temperature to be more uniform by adjusting the flowing direction of the aluminum liquid in the heating region.

Owner:SUZHOU LONGRAY THERMAL TECH

A revetment structure and breakwater

The invention relates to the technical field of oceanographic engineering, in particular to a bank protection structure and a breakwater. The structure comprises a bottom plate and at least three sideplates; included angles larger than 0 degree and smaller than 90 degrees are formed between the side plates and the bottom plate, and the side plates and the bottom plate are fixedly connected; a containing cavity is formed between the bottom plate and the side plates, and solid matter is placed in the containing cavity; the structure is formed by splicing the bottom plate and the side plates, the bottom plate and the side plates can be subject to machining and filed assembling on site, in the loading and unloading process, the structure is rapid and convenient, the structure is filled with the solid matter, the self weight can be increased, and the structure can be prevented from moving or toppling due to wave washing. According to the breakwater, plants are cultivated in the structure,a biological protection function is formed, root systems of the plants can extend and grow in adjacent structures, interconnection and interlocking between the structures can be formed, the structure,whole breakwater and breakwater protection face stability can be increased, and the scour erosion to the blowing and filling island making shore can be reduced.

Owner:OCEAN UNIV OF CHINA

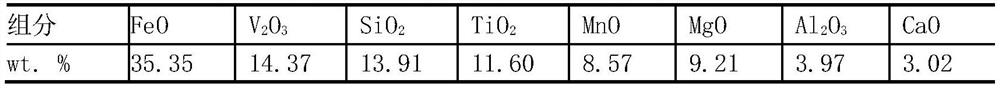

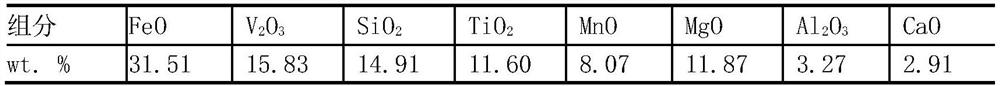

A pretreatment method for high magnesium vanadium slag based on magnesizing roasting

ActiveCN111534661BWell mixedReduce scour erosionManufacturing convertersPartial oxidationPretreatment method

The invention discloses a method for producing and pretreating high-magnesium vanadium slag based on magnesizing roasting, and belongs to the technical field of vanadium metallurgy. The invention provides a new idea for solving the three-waste disposal problem and the unutilized waste heat of vanadium slag in the existing vanadium extraction process by sodium and calcification methods. The steps are: after the molten iron is mixed into the converter, add coolant and raw materials containing magnesia, and use top-blown oxygen and bottom-blown nitrogen / argon for blowing; after blowing, leave the high-magnesium vanadium slag in the converter for pretreatment, The bottom blowing gas is switched to oxygen; the cooled pretreated vanadium slag is crushed and ground in a conventional way, and roasted without salt for a short time. The invention directly generates high-magnesium vanadium slag in the converter and utilizes the waste heat of the vanadium slag to complete the partial oxidation of the vanadium slag, thereby creating favorable conditions for subsequent simplification of the roasting process and reduction of roasting costs.

Owner:CHONGQING UNIV

A Method of Improving the Service Life of Converter Oxygen Lance

The invention relates to a method of prolonging the service life of an oxygen lance of a converter. The method comprises the following steps: carrying out treatment on bottom end surface of a spray head of the oxygen lance and treatment on side wall of an oxygen lance body, coating a high-temperature-resistant antioxidant coating to the bottom end surface of the spray head of the oxygen lance, carrying out induction heating or flame heating treatment on the end surface, spraying a first layer with a coal gas type flame high pressure spray gun, and spraying a second layer with an oxygen-acetylene flame high pressure spray gun; derusting the side wall of the gun body to a range 2-10 m far from the bottom end surface by taking the bottom end surface of the spray head of the oxygen lance as the starting point, and then smearing a coating; and spraying boron nitride powder to the coating by using the oxygen-acetylene flame high pressure spray gun. The method has the advantages that the service life of the oxygen lance is prolonged, and the labor intensity of workers is alleviated to a great extent; the deslagging treatment time as slag is attached to the oxygen lance is saved, the blowing rhythm is more compact, the effective operating efficiency of the converter is increased, and the output of steel is improved.

Owner:ANGANG STEEL CO LTD

A tidal tributary estuary water ecosystem and its construction method in the post-dam dewatering reach

ActiveCN111747532BImprove purification efficiencyImprove purification effectClimate change adaptationCoastlines protectionEnvironmental engineeringEstuary

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

A pressure-regulating precision casting method for superalloy floating wall tiles under the action of an external electromagnetic field

ActiveCN110421144BQuality improvementImprove inner qualityFoundry moulding apparatusSuperalloyForced convection

The invention provides a high-temperature alloy floating wall tile pressure-regulating precision casting method with the action of an external electromagnetic field, comprising: using 3D printing technology to print a wax mold of the gating system; atomizing and polishing the wax mold to remove the surface of the wax mold layer pattern; prepare a multi-layer shell on the wax mold; then demould the shell; use vacuum anti-gravity pressure regulation to pour the superalloy melt into the shell of the shell to form a casting. The variable electromagnetic field makes the electromagnetic body force in the process of filling and solidification stir the superalloy melt, and produces forced convection to change the temperature field and concentration field of the superalloy melt and refine the grains. The invention cooperates with the pressure regulating casting device to apply an alternating electromagnetic field during the filling and solidification process of the casting, realizes the effect of electromagnetic stirring and forced convection, improves the metallurgical quality of the casting, reduces internal defects, and increases the density.

Owner:上海鑫凝控材料科技有限公司

Side burning device structure of float glass smelting kiln

The invention discloses a side burning device structure of a float glass smelting kiln, comprising a side wall of the float glass smelting kiln, a burner guide hole is arranged on the side wall, an arc-shaped burner is arranged in the burner guide hole, and the central angle of the arc-shaped burner is 50 degrees-80 degrees. Since the arc-shaped burner is adopted and is inserted to the arc-shapedburner hole of a side burning hole brick and the side burning hole brick is inserted to the burner guide hole and is tightly attached to the wall of the burner guide hole, the invention solves the problems of sealing between the burner guide hole and the arc-shaped burner well, and meanwhile, due to the adoption of the arc-shaped structure of the adopted burner, the invention breaks through the traditional structure form so that the nozzle angle of the arc-shaped burner can be adjusted to the optimum spraying angle, thereby ensuring the spraying angle of flames, avoiding the situation of mutual interference of the flames at both sides, and then fuels can fully burn in the smelting kiln; and besides, the arc-shaped structure reduces the washing erosion of the flames on small furnace side walls.

Owner:长利玻璃洪湖有限公司

Water-cooled spray gun for blowing high-temperature oxidizing gas and method for blowing oxidizing gas

ActiveCN112708723AExacerbate burnoutAvoid entrainmentManufacturing convertersElectric furnaceInsulation layerThermal break

The invention discloses a water-cooled spray gun for blowing high-temperature oxidizing gas and a method for blowing the oxidizing gas. The spray gun comprises a gun core and a water jacket. The gun core is inserted into the water jacket. The gun core comprises a gun body and a gun head, the water jacket comprises a jacket body and a jacket head, and the gun head of the gun core and the jacket head of the water jacket are made of metal materials with high heat conductivity coefficients. The gun body of the water-cooled spray gun for blowing the high-temperature oxidizing gas communicates with a pipeline for conveying the high-temperature oxidizing gas, and the gun head communicates with a metallurgical furnace, so that blowing of the oxidizing gas is completed. According to the water-cooled spray gun for blowing the high-temperature oxidizing gas and the method for blowing the oxidizing gas, the internal energy-kinetic energy conversion rule of gas in a gun head spray pipe is fully utilized, a protective coating and a vacuum heat insulation layer are ingeniously arranged, heat exchange between cooling water and the high-temperature oxidizing gas can be effectively blocked, oxidation corrosion of the high-temperature oxidizing gas to the pipeline can also be restrained, and cooling of the end of the spray gun can also be enhanced.

Owner:SUZHOU UNIV

Arid region ecological remediation control system and control method based on 5G network

ActiveCN111213537AReduce slopeReduce scour erosionSewerage structuresFlow control using electric meansEnvironmental resource managementEnvironmental engineering

The invention discloses an arid region ecological remediation control system and control method based on 5G network. The arid region ecological remediation control system comprises rainfall monitoringmodules, 5G communication modules, a cloud treatment system, a water and sand filtering plate control module and the like, wherein the ecological remediation region is divided into a plurality of small regions, the rainfall monitoring module is arranged in each small region, and can be used for obtaining rainfall data of each small region within a certain period; and the 5G communication module is arranged in each small region, and can be used for transmitting the rainfall data to the cloud treatment system; the cloud treatment system can transmit instruction to control the water and sand filtering plate control module; and the water and sand filtering plate control module can be used for regulating flow of permeability of unit length or length of the water and sand filtering plate to realize water separation and precipitation and reinforce ecological remediation reliability.

Owner:ZHEJIANG YINGLUOHUA NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com