A pretreatment method for high magnesium vanadium slag based on magnesizing roasting

A high-magnesium vanadium slag and pretreatment technology, which is applied in the field of vanadium-titanium metallurgy, can solve problems such as the difficulty in solving the three wastes of the sodium chemical method, and achieve the effects of simplifying the pretreatment process, reducing erosion and erosion, and suppressing the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

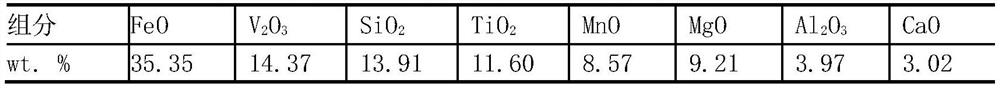

Embodiment 1

[0021] A kind of high-magnesium vanadium slag production and pretreatment method based on magnesizing roasting is characterized in that, comprises the following steps:

[0022] (1) In the process of using vanadium-titanium-magnetite as raw material for steelmaking, after 125T molten iron is blended into the converter, 16kg / t Fe coolant (scrap, iron oxide scale, iron ore, etc.) is added within 3 minutes before the start of oxygen blowing , within 2 minutes after adding the coolant, add 8 kg / t Fe of the mixture of magnesia and waste furnace lining (in which the MgO content is above 90%, and the CaO content is about 2%), and the MgO / V in the vanadium slag 2 o 5 The mass ratio is controlled at 0.4 to 0.5.

[0023] Use top-blown oxygen and bottom-blown nitrogen for blowing; the intensity of top-blown oxygen supply is 3m 3 / (min·tFe), oxygen blowing time is 6min, oxygen pressure is 0.9MPa; bottom blowing nitrogen flow rate is 0.4m 3 / (min·tFe). The molten pool temperature during...

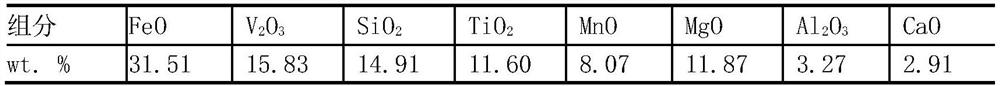

Embodiment 2

[0032] A kind of high-magnesium vanadium slag production and pretreatment method based on magnesizing roasting is characterized in that, comprises the following steps:

[0033] (1) In the process of using vanadium-titanium magnetite as raw material for steelmaking, after 125T molten iron is blended into the converter, 25kg / t Fe coolant (scrap, iron oxide scale, iron ore, etc.) is added within 3 minutes before the start of oxygen blowing , add magnesia 4kg / t Fe within 2min after adding coolant, MgO / V in vanadium slag 2 o 5 The mass ratio is controlled at 0.6-0.7.

[0034] Top-blown oxygen and bottom-blown nitrogen are used for blowing; the strength of top-blown oxygen supply is 2.5m 3 / (min·tFe), oxygen blowing time is 6.5min, oxygen pressure is 0.8MPa; bottom blowing nitrogen flow rate is 0.4m 3 / (min·tFe). Blowing is carried out by blowing oxygen with an oxygen lance, and the blowing time is 6.5 minutes. The molten pool temperature during the blowing process does not exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com