Composite sewing thread of silk and yarn covering structure

A composite material and sewing thread technology, which is applied in the field of sewing thread, can solve the problems of poor wear resistance of sewing thread and low dust removal efficiency of dust filter bags, and achieve the effects of reducing wear and tear, reducing the risk of filter bag rupture, and reducing the rate of thread breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

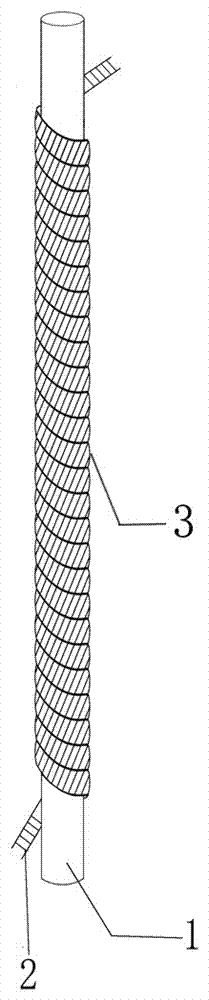

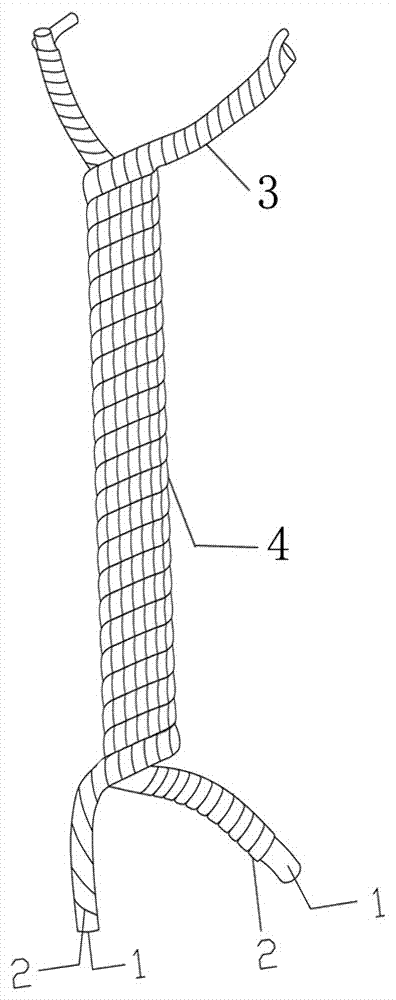

[0031] Step 1, use a round 440dtex polytetrafluoroethylene monofilament produced by the "paste extrusion" process as the core wire 1, and a 20S polyphenylene sulfide single yarn as the outer covering yarn 2, through the covering yarn machine Covering is performed to form a covered yarn 3 . The twist direction of the covering twist is 520T / m, and the twist direction is "S"; the twist of the single yarn of the outer covering yarn 2 is 520T / m, and it is carded and spun using polyphenylene sulfide fibers with a linear density of 1.8dtex and a shear length of 51mm.

[0032] Step 2: Take two covered yarns 3 formed by the above-mentioned process, and carry out parallel twisting and plying through a plying machine to form a sewing thread 4 with a twist of 480 T / m and Z twist.

[0033] Step 3, after the above-mentioned polytetrafluoroethylene monofilament and polyphenylene sulfide covered yarn 3 are twisted and plied into a thread, they need to be shaped by a heating plate blanching se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com