High-cleanliness spring steel and production method thereof

A production method and high cleanliness technology, applied in the production of high cleanliness spring steel, in the field of high cleanliness spring steel, can solve the problems of high number and density of inclusions, the performance of spring steel cannot meet the market demand, and the size of inclusions is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Pretreatment

[0055] The hot metal from the blast furnace is desulfurized in the KR desulfurization unit. The chemical composition of the desulfurizer used includes: CaO 80190%, CaF 2 10115%, and the rest are unavoidable impurities; the slag removal rate of desulfurization is 97%.

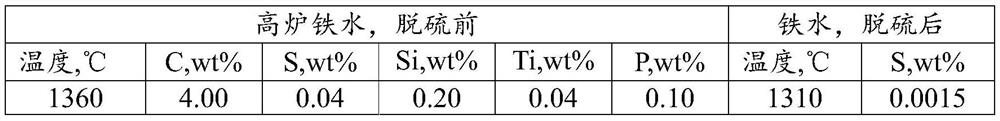

[0056] Among them, the temperature, C content, S content, Si content, Ti content, P content of the blast furnace molten iron, the temperature of the molten iron after desulfurization, and the S content in the molten iron after desulfurization are shown in Table 1.

[0057] [Table 1]

[0058]

[0059] (2) Converter smelting

[0060] The molten iron after pretreatment is mixed with high-quality scrap steel with a thickness of 2 mm to form molten steel and loaded into a converter for desiliconization, dephosphorization, and oxygen blowing decarburization. Scrap steel meets: S≤0.012%, P≤0.015%, Ti≤0.015% scrap steel;

[0061] Use a slide plate to block slag and tap slag. At the begi...

Embodiment 2

[0078] (1) Pretreatment

[0079] The hot metal from the blast furnace is desulfurized in the KR desulfurization unit. The chemical composition of the desulfurizer used includes: CaO 80190%, CaF 2 10115%, and the rest are unavoidable impurities; the slag removal rate of desulfurization is 98%.

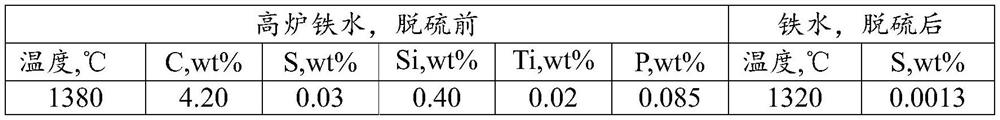

[0080] Among them, the temperature, C content, S content, Si content, Ti content, P content of the blast furnace molten iron, the temperature of the molten iron after desulfurization, and the S content in the molten iron after desulfurization are shown in Table 4.

[0081] [Table 4]

[0082]

[0083] (2) Converter smelting

[0084] The pretreated molten iron is mixed with high-quality steel scrap with a thickness of 1 mm to form molten steel and loaded into a converter for desiliconization, dephosphorization, and oxygen blowing decarburization. Scrap steel meets: S≤0.012%, P≤0.015%, Ti≤0.015% scrap steel;

[0085] Use a slide plate to block slag and tap slag. At the beginning of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com