Side burning device structure of float glass smelting kiln

A technology of float glass and device structure, which is applied in the field of structural devices to realize side-firing production of float glass melting furnaces, and can solve problems such as small contact area between combustion-supporting air and fuel, uneven and effective mixing, erosion of small furnace side walls, etc. problems, to achieve the effect of shortening the black area, increasing the effective heat transfer area, and reducing erosion and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

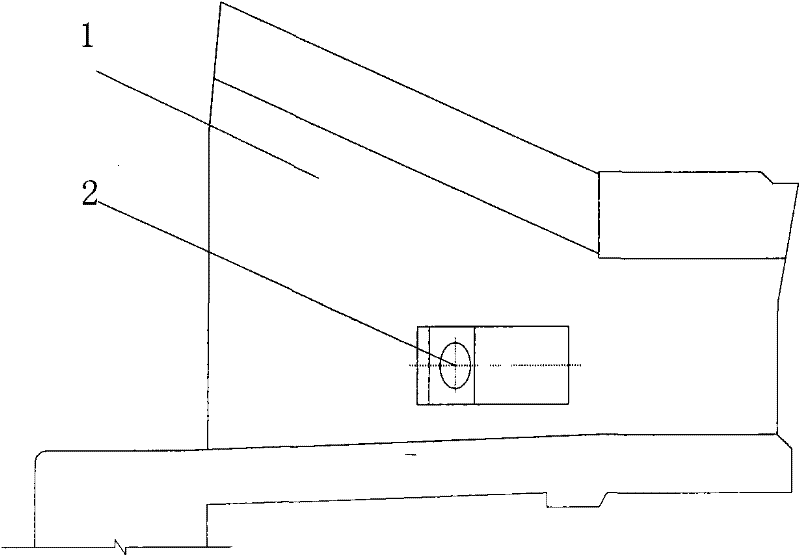

[0022] like figure 1 As shown, it is a side wall 1 of a small furnace, and the lower part of the side wall 1 is provided with a burner guide hole 2 .

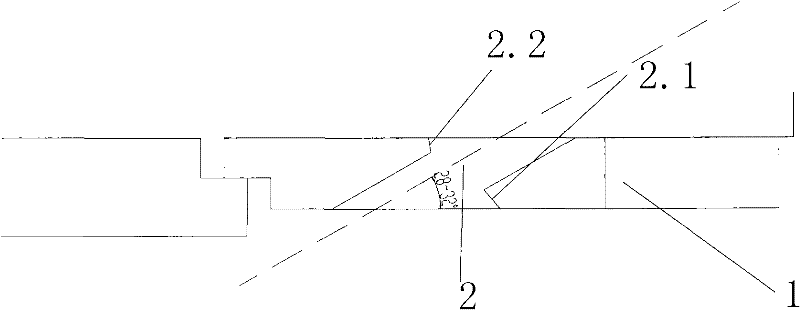

[0023] The structure of the burner guide hole 2 is as follows figure 2 As shown, the burner guide hole and the axis of the side wall are arranged obliquely, and the angle between the center line of the burner guide hole and the axis of the side wall is 25° to 35°, and the optimum angle is 28° to 32°. A first limit plane 2.1 is set on the outer side of the side wall in one end of the burner guide hole 2, and a second limit plane 2.2 is set on the inner side of the side wall in the other end of the burner guide hole 2. The first limit plane 2.1 and the second limit plane 2.1 Plane 2.2 is relatively misaligned. The first limit plane 2.1 and the second limit plane 2.2 are arranged in a relative dislocation, which can ensure that the side-burning brick 3 is inserted between the two limit planes.

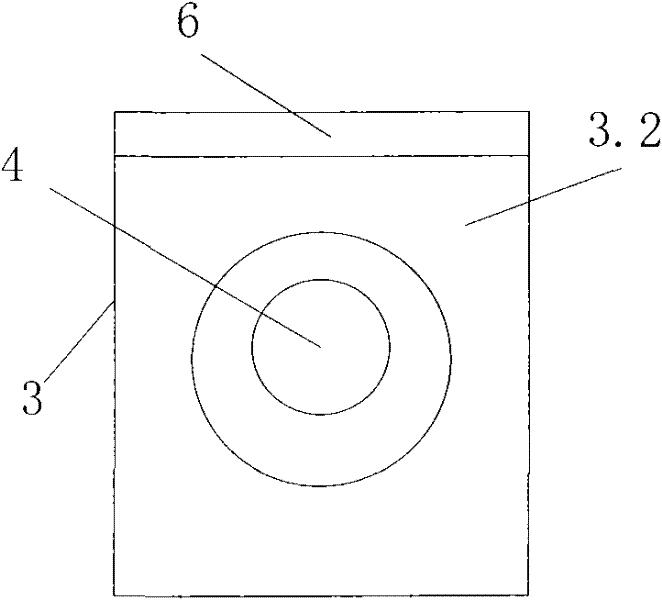

[0024] The structure of side bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com