Water-cooled spray gun for blowing high-temperature oxidizing gas and method for blowing oxidizing gas

A high-temperature oxidation, water-cooled technology, applied in the field of water-cooled spray gun and oxidizing gas injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

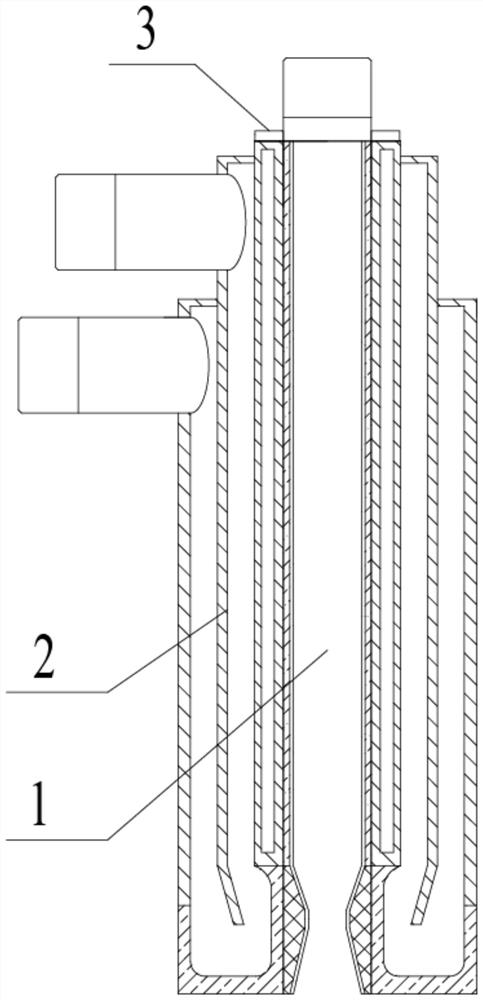

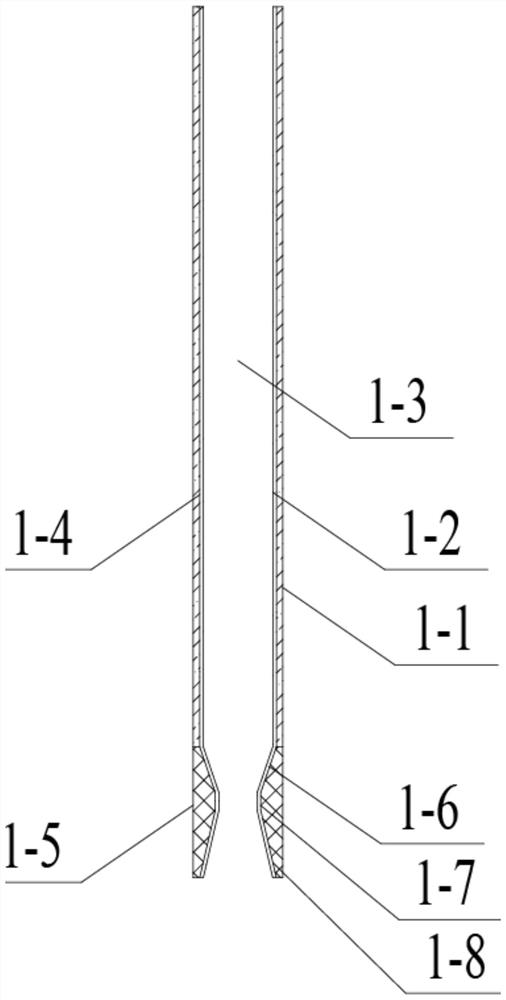

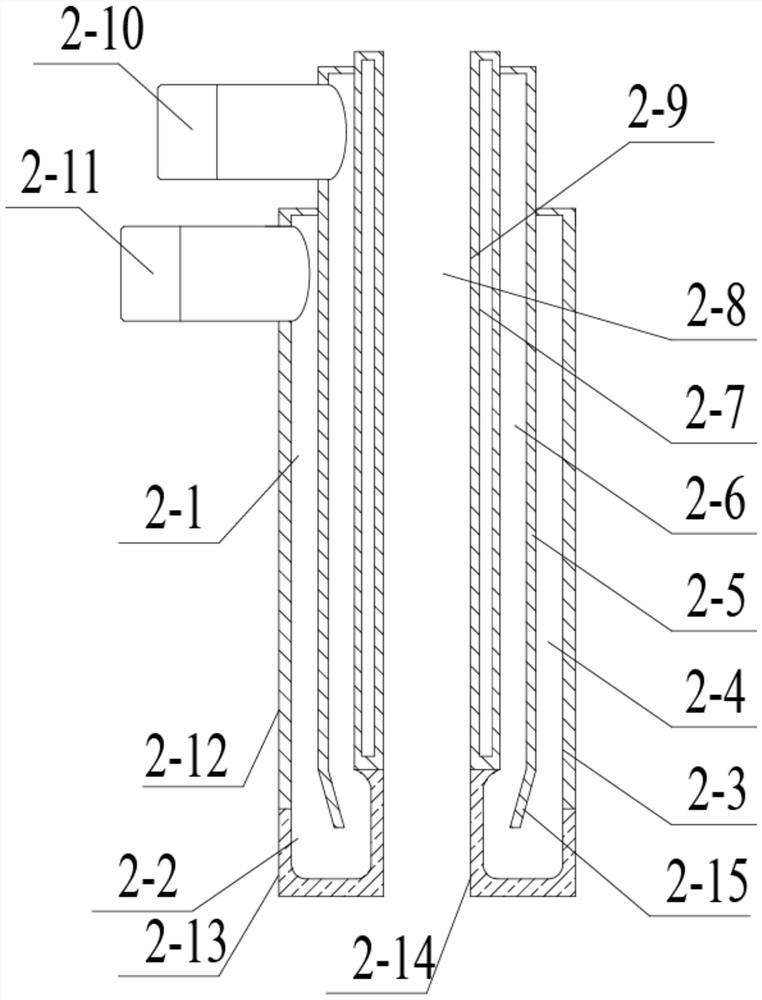

[0036] See attached Figure 1-4 :

[0037]A water-cooled spray gun for blowing high-temperature oxidizing gas, including a gun core 1 and a water jacket 2; the gun core is inserted into the water jacket; the gun core includes a gun body 1-4 and a gun head 1-5; the gun head is from top to bottom Including rounded table-shaped pipe 1-6, straight pipe 1-7, round table-shaped pipe 1-8; water jacket includes sleeve body 2-1 and sleeve head 2-2; sleeve body includes inner wall 2-7, water baffle 2-5 , outer wall 2-3; one end of the sheath is connected to the inner wall, and the other end is connected to the outer wall; the inner wall of the gun core is provided with a protective coating, and the gun core is inserted into the water jacket to form a spray gun. After the combination, the lower end of the gun core and the water jacket are flush , the gun core can be pulled out from the water jacket, and the gun core can be replaced;

[0038] The gun core is hollow as the high-temperatu...

Embodiment 2

[0046] On the basis of Example 1, the hollow layer on the inner wall of the jacket is evacuated, and the width of the vacuum structure is 3mm, which further reduces the thermal conductivity and enhances the heat insulation effect; the rest remain unchanged.

Embodiment 3

[0048] On the basis of Example 1, the lower end of the baffle is a vertical structure (see Figure 5 ); the rest remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com